Back-washing regeneration method of ceramic membrane method brine refining process filter

A brine refining and filtering technology, which is applied in chemical instruments and methods, fixed filter element filters, filtration and separation, etc., can solve problems such as dirty mud removal, affecting the high-flux production capacity of ceramic membranes, and affecting normal production, etc. Achieve the effects of increasing energy consumption, prolonging the regeneration cleaning cycle, and prolonging the production running time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

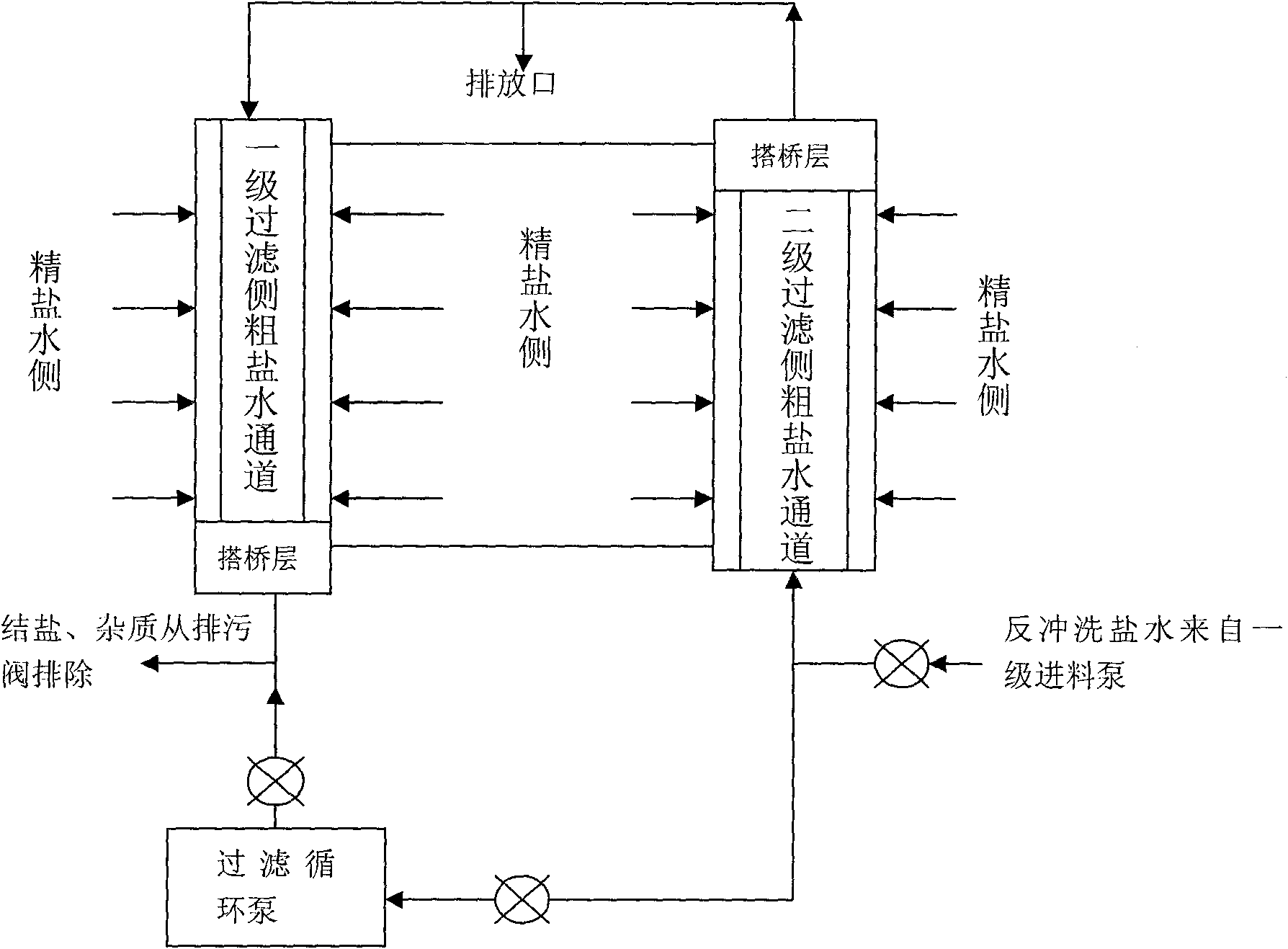

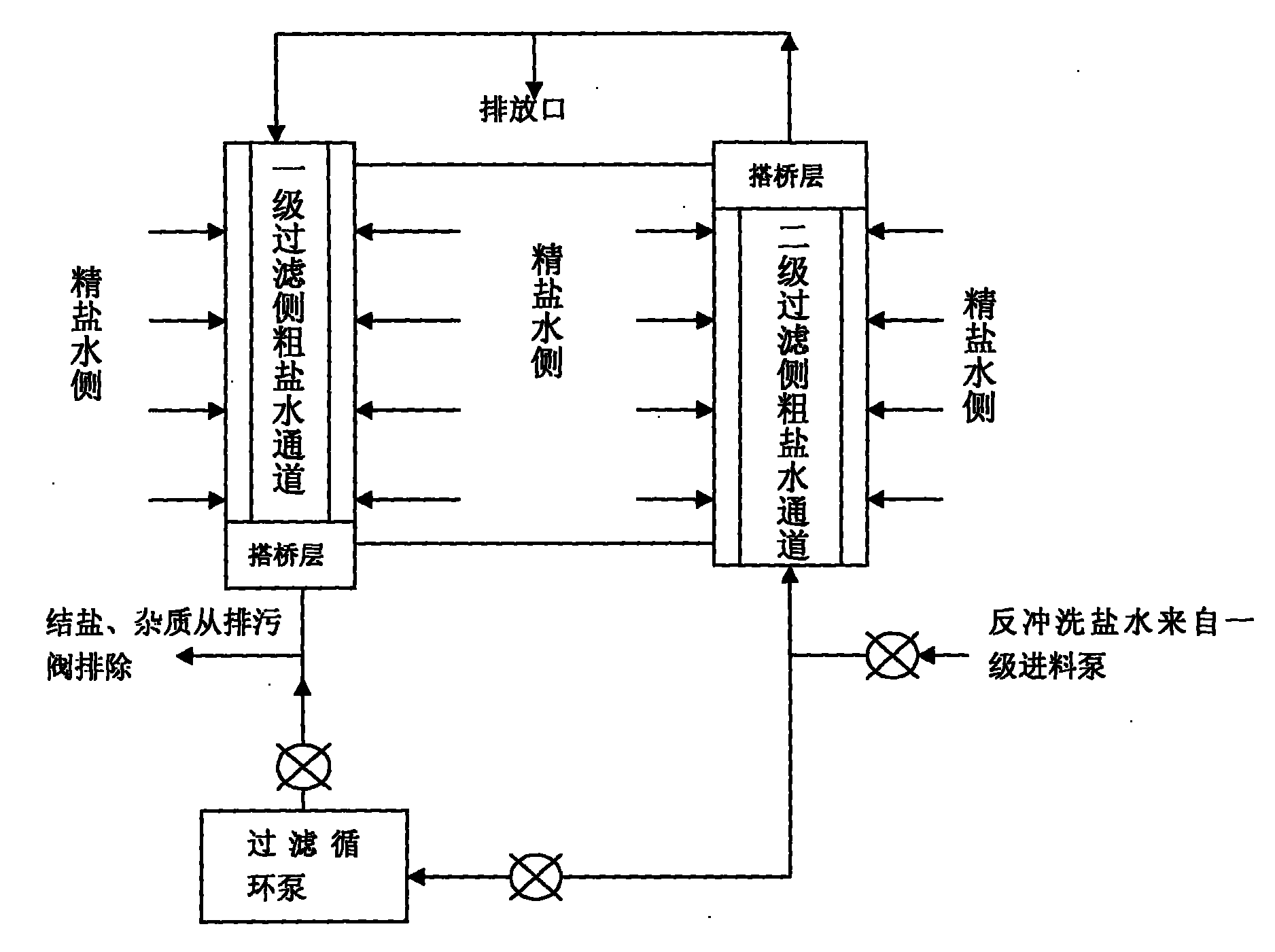

[0012] When salt mud and fibrous impurities form ceramic membrane tubes to bridge and block the initial stage, backwash regeneration should be carried out. The specific steps are as follows:

[0013] a. When the filtration pressure on the primary side of the filter rises to 0.45MPa, close the refined brine outlet valve, isolate unqualified brine from entering the refined brine system, stop the operation of the filtration circulation pump, and reduce the pressure on the end face of the primary inlet membrane tube to 0.15-0.2 MPa.

[0014] b. Open the bottom valve of the first-stage side sewage of the filter and the return valve of unqualified brine, and turn on the first-stage feed pump, so that the coarse brine flows from the second stage to the reverse direction of the first stage at a pressure of 0.2-0.28MPa, and the flow rate is 0.7m / s , to form a brine back flushing pressure difference of 0.12-0.15MPa, to separate the salt mud agglomeration and impurities on the inner wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com