Self-cleaning method for filter assembly of washing machine

a washing machine and filter assembly technology, applied in the field of washing machines, can solve the problems of filter membrane, large waste of water resources, large water consumption of the entire laundry process, etc., and achieve the effect of prolonging the service life of the filter assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

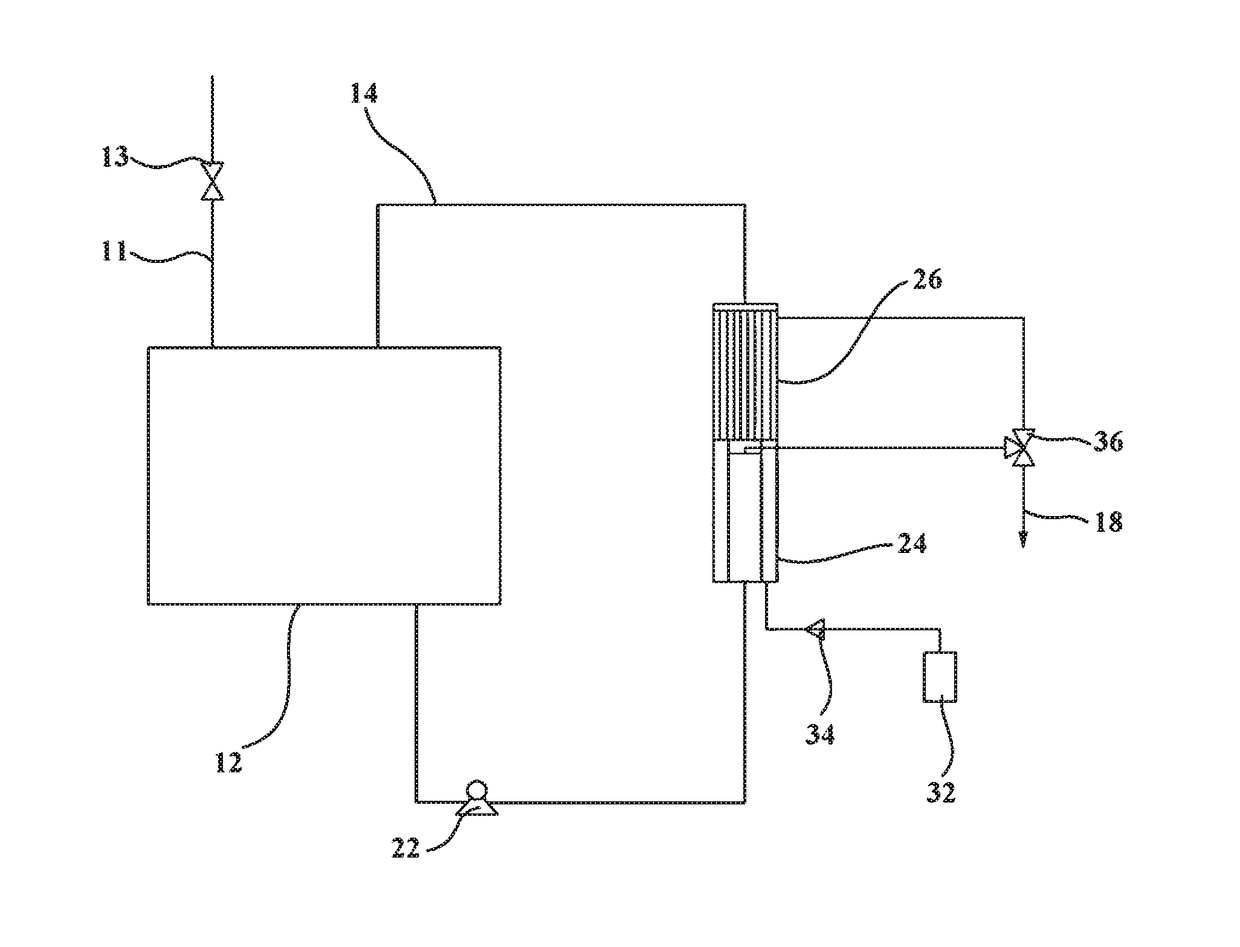

[0031]FIG. 1 is a schematic diagram of a washing machine according to an embodiment of the present invention. The washing machine may comprise a washing tub 12, a drainage pump 22, and a filter assembly. The filter assembly comprises a front filter 24 and an ultrafiltration membrane assembly 26. The washing tub 12 is usually composed of an outer tub and an inner tub which is rotatable within the outer tub. An upper part of the washing tub 12 is provided with a fresh water inlet which is connected to a water supply port through a pipeline 11, and when a valve 13 on the pipeline 11 is opened, fresh washing water or fresh rinsing water may enter the washing tub 12. A lower part of the washing tub 12 is provided with a drainage port, and the drainage port is in communication with the filter assembly via a drainage pump 22 through a pipeline. A water output port of the ultrafiltration membrane assembly 26 is in communication with the washing tub 12 through a water intake pipeline 14.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com