Advanced treatment and reuse method of high-temperature nitrochlorobenzene wastewater

A technology of nitrochlorobenzene and high-temperature wastewater, which is applied in natural water treatment, water/sludge/sewage treatment, osmosis/dialysis water/sewage treatment, etc., to reduce the addition of fungicides and reducing agents, good removal effect, adaptable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

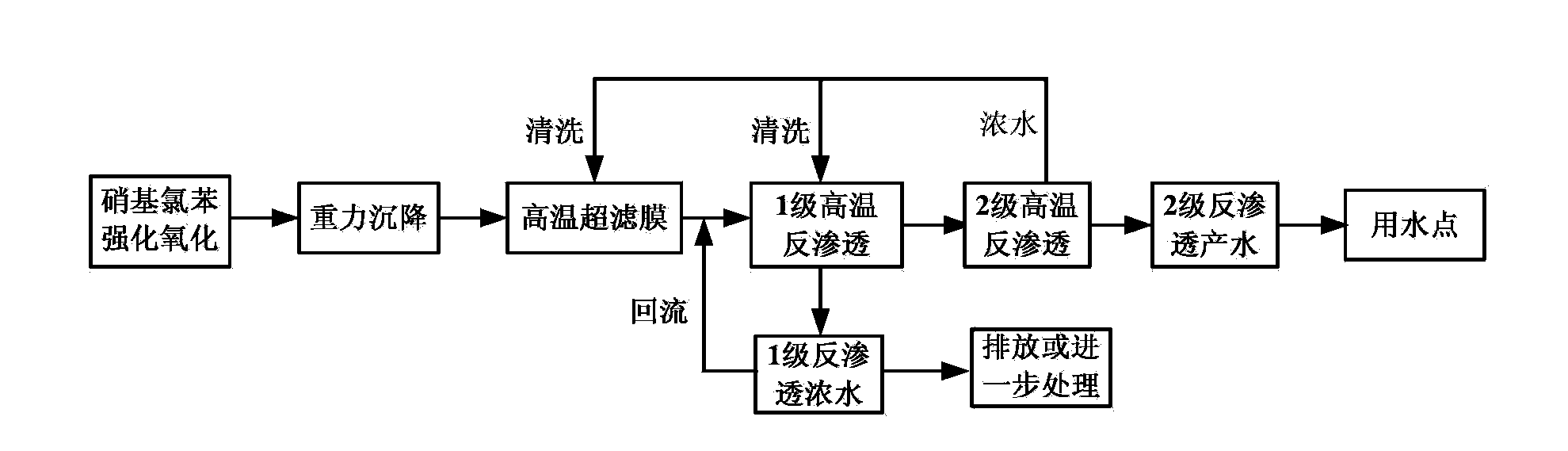

[0036] The treatment process of the produced water after the enhanced oxidation-gravity sedimentation of nitrochlorobenzene wastewater is as follows: figure 1 As shown, the main characteristics of the water quality of the produced water include: temperature 55°C, pH 7.0, COD 80mg / L, chroma 150 times, total iron content 30mg / L, conductivity 15000μs / cm, Cl - The content is 100mg / L. The process water after 55°C enhanced oxidation-sedimentation is sent to the ultrafiltration membrane system of cross-flow filtration through the ultrafiltration feed water pump. The ultrafiltration uses 0.01 μm PVDF hollow fiber ultrafiltration membrane, and the effective membrane area is 45m 2 , the membrane filtration flux is 180L / m when the water supply pressure is 0.3bar 2 h, the recovery rate of the ultrafiltration system is adjusted to 50%, and the ultrafiltration concentrated water is circulated to the gravity sedimentation tank of the enhanced oxidation process; the water quality of the ultr...

Embodiment 2

[0040] The treatment process of the produced water after the enhanced oxidation-gravity sedimentation of nitrochlorobenzene wastewater is as follows: figure 1 As shown, the main characteristics of the water quality of the produced water include: temperature 60°C, pH 7.5, COD 90mg / L, chroma 160 times, total iron content 35mg / L, conductivity 25000μs / cm, Cl - The content is 120mg / L. The process water after 60°C enhanced oxidation-sedimentation is sent to the ultrafiltration membrane system of cross-flow filtration through the ultrafiltration feed water pump. The ultrafiltration under high temperature conditions uses 0.1 μm PTFE hollow fiber ultrafiltration membrane with an effective membrane area of 50m 2 , the membrane filtration flux is 126L / m when the water supply pressure is 0.25bar 2 h, the recovery rate of the ultrafiltration system is adjusted to 55%, and the concentrated ultrafiltration water is circulated to the gravity sedimentation tank of the enhanced oxidation pro...

Embodiment 3

[0044] The treatment process of the produced water after the enhanced oxidation-gravity sedimentation of nitrochlorobenzene wastewater is as follows: figure 1 As shown, the main characteristics of the water quality of the produced water include: temperature 65°C, pH 8.0, COD 100mg / L, chroma 180 times, total iron content 55mg / L, conductivity 30000μs / cm, Cl - The content is 200mg / L. The process water after 65°C enhanced oxidation-sedimentation is sent to the ultrafiltration membrane system through the ultrafiltration feed water pump. The ultrafiltration under high temperature conditions uses 0.05μm PES hollow fiber curtain ultrafiltration membrane modules, and the effective membrane area is 48m 2 , the membrane filtration flux is 91L / m under the condition of negative pressure of -0.5bar 2 h, the ultrafiltration concentrated water is sent to the gravity sedimentation tank of the enhanced oxidation process through the circulating pump; the water quality of the ultrafiltration mem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com