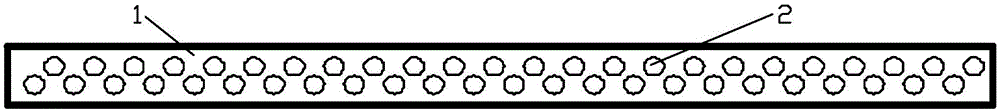

Multi-channel kaolin plate ceramic membrane support, preparation method and application thereof

A ceramic membrane support and kaolin technology, applied in the field of ceramic membranes, can solve the problems of easy cracking during sintering, harmful to the health of production personnel, and low production efficiency, and achieve easy process control, wide application range and high porosity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1) In terms of parts by mass, 95 parts of kaolin ceramic aggregate with an average particle size of 180 μm, 1 part of pore-forming agent activated carbon powder with a particle size of 20 μm, 1 part of dispersant polyvinyl alcohol (PVA) powder with a molecular weight of 2000 and After mixing 3 parts of gelatin powder, a gel injection molding binder with a purity of 98%, ball milling for 2 to 4 hours to obtain a mixed powder, add RO water at a volume ratio of 2.2:1 between the mixed powder and RO water, and heat in a water bath to 85°C, ball milling for 20 hours to obtain slurry;

[0034] 2) Maintain the temperature of the slurry at 80°C. After vacuum defoaming, immediately inject the slurry into a flat film forming mold, and form it in situ at 20°C to obtain a wet billet; a number of tubular or rod-like molds extending through the channels of the opposing side walls;

[0035] 3) Demould the above-mentioned wet blank, dry in the shade at room temperature for 24 hours, d...

Embodiment 2

[0040] 1) In terms of parts by mass, 80 parts of kaolin ceramic aggregate with an average particle size of 1 μm, 5 parts of pore-forming agent starch with a particle size of 1 μm, 5 parts of dispersant polyethylene glycol (PEG) powder with a molecular weight of 1000 and After 10 parts of gel injection molding binder agar powder with a purity of 98% were mixed, ball milled for 4 hours to obtain a mixed powder, and the volume ratio of the mixed powder to RO water was 1.5:1 by adding RO water, and heated in a water bath to 45 °C, ball milled for 18 hours to obtain slurry;

[0041] 2) Maintain the temperature of the slurry at 45°C. After vacuum defoaming, immediately inject the slurry into a flat film forming mold, and form it in situ at 15°C to obtain a wet billet; a number of tubular or rod-like molds extending through the channels of the opposing side walls;

[0042] 3) Demould the above-mentioned wet blank, dry in the shade at room temperature for 72 hours, dry at 60°C for 12...

Embodiment 3

[0047] 1) In terms of parts by mass, 90 parts of kaolin ceramic aggregate with an average particle size of 100 μm, 3 parts of pore-forming agent activated carbon powder with a particle size of 10 μm, and 2 parts of dispersant methyl cellulose (MC) powder with a molecular weight of 2800 After mixing with 5 parts of gel injection molding binder agarose powder with a purity of 98%, ball milling for 3 hours to obtain a mixed powder, add RO water at a ratio of 1.8:1 by volume of the mixed powder and RO water, and heat in a water bath to 75°C, ball milling for 12 hours to obtain slurry;

[0048] 2) Maintain the temperature of the slurry at 75°C. After vacuum defoaming, immediately inject the slurry into a flat film forming mold, and form it in situ at 25°C to obtain a wet billet; a number of tubular or rod-like molds extending through the channels of the opposing side walls;

[0049] 3) Demould the above-mentioned wet blank, dry in the shade at room temperature for 48 hours, dry at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com