Washing machine filtering assembly self-cleaning method

A filter component and self-cleaning technology, which is applied to the control device of washing machines, other washing machines, washing devices, etc., can solve the problems of cleaning agent residue, incomplete cleaning of filter components, and influence of filtering effect, etc., and achieve the effect of prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

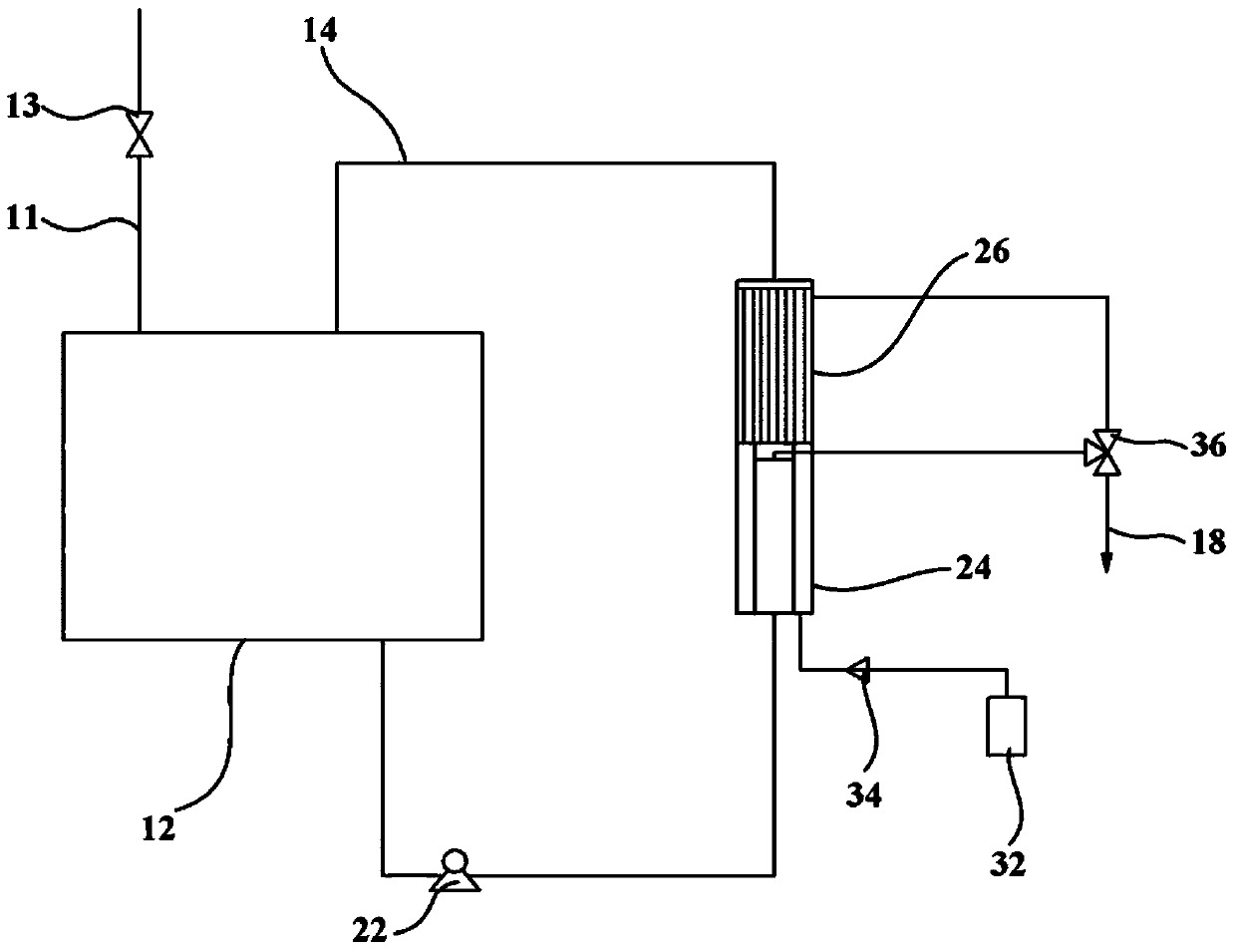

[0031] figure 1 is a schematic schematic diagram of a washing machine according to an embodiment of the present invention. The washing machine may include a washing tub 12, a drain pump 22, and a filter assembly. The filter assembly includes a pre-filter 24 and an ultrafiltration membrane assembly 26 . The washing tub 12 is generally composed of an outer tub and an inner tub that can rotate in the outer tub. Washing tub 12 top is provided with clear water inlet, and it connects tap water outlet by pipeline 11, when opening valve 13 on the pipeline 11, can enter washing with clear water or rinse with clear water in washing tub 12. The lower part of the washing tub 12 is provided with a drain port, and the drain port communicates with the filter assembly via a drain pump 22 through a pipeline. The water production port of the ultrafiltration membrane module 26 communicates with the washing tub 12 through the water inlet pipeline 14 . When using the clean water washing functi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com