Preparation method of polyvinylidene fluoride/graphene oxide composite ultrafiltration membrane

A kind of polyvinylidene fluoride, graphene composite technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

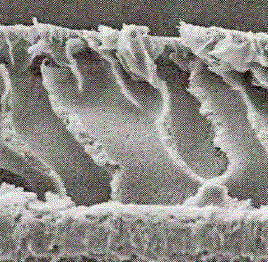

Image

Examples

Embodiment Construction

[0019] A preparation method of polyvinylidene fluoride / graphene oxide composite ultrafiltration membrane: preliminary preparation: (1) spare the following materials: adopt graphene oxide prepared by Hummers oxidation method as hydrophilic additive, polyvinylidene fluoride as membrane substrate, N , N-methylacetamide is used as a solvent, and deionized water is used as a coagulation bath; (2) Dry the material in step (1) in a vacuum oven at 80°C for at least 12 hours to remove the moisture absorbed by the material;

[0020] Production process: ① Accurately weigh a certain mass of graphene oxide, disperse it in N,N-methylacetamide solution, and ultrasonically treat it for at least 10 hours to obtain a fully exfoliated bulk liquid;

[0021] ② Stir and dissolve the polyvinylidene fluoride powder in the N,N-methylacetamide solution at 70°C, mix the graphene oxide dispersion with the polyvinylidene fluoride casting solution, stir for 24 hours, and ultrasonicate for 2 hours, To obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com