Stainless steel pipe type multilayer sintering filter screen precision filtering device capable of realizing backwashing

A precision filtration, stainless steel technology, applied in fixed filter element filters, filtration separation, chemical instruments and methods, etc., can solve the problems of inconvenient and incomplete cleaning, low degree of automation, and high labor costs, saving filtration time and processing. Mature craftsmanship and good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

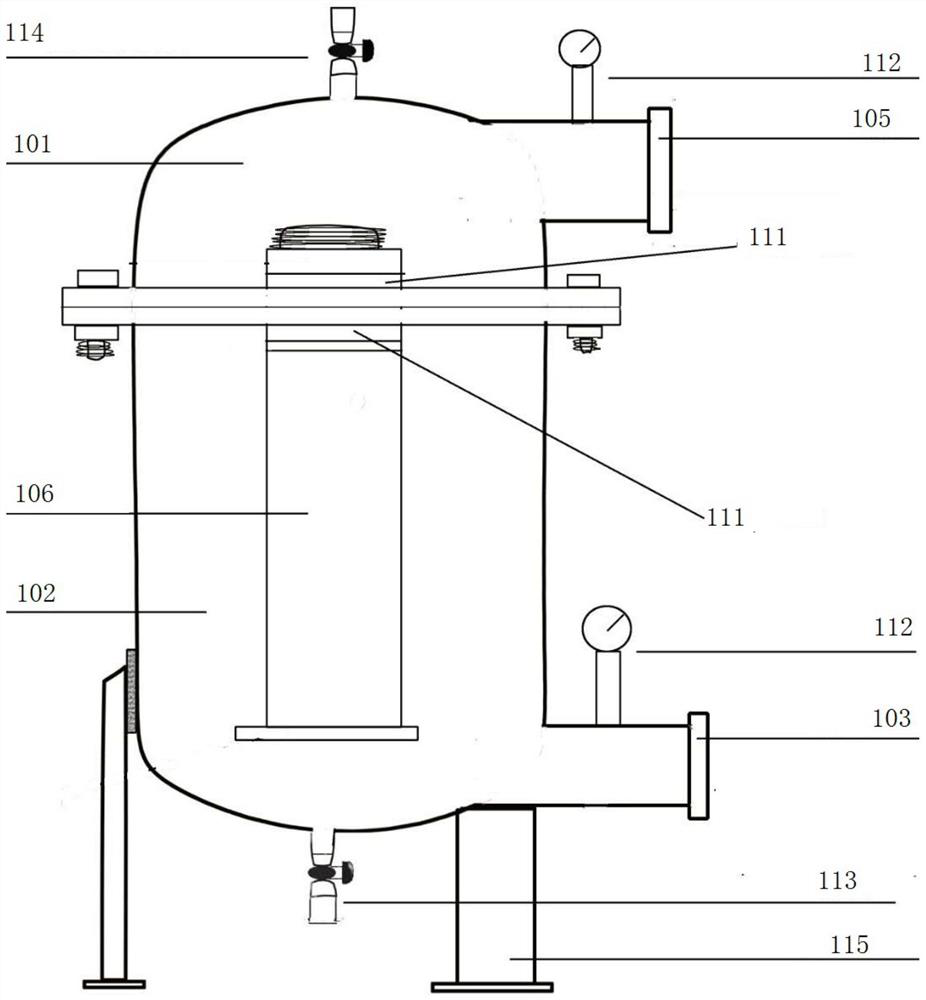

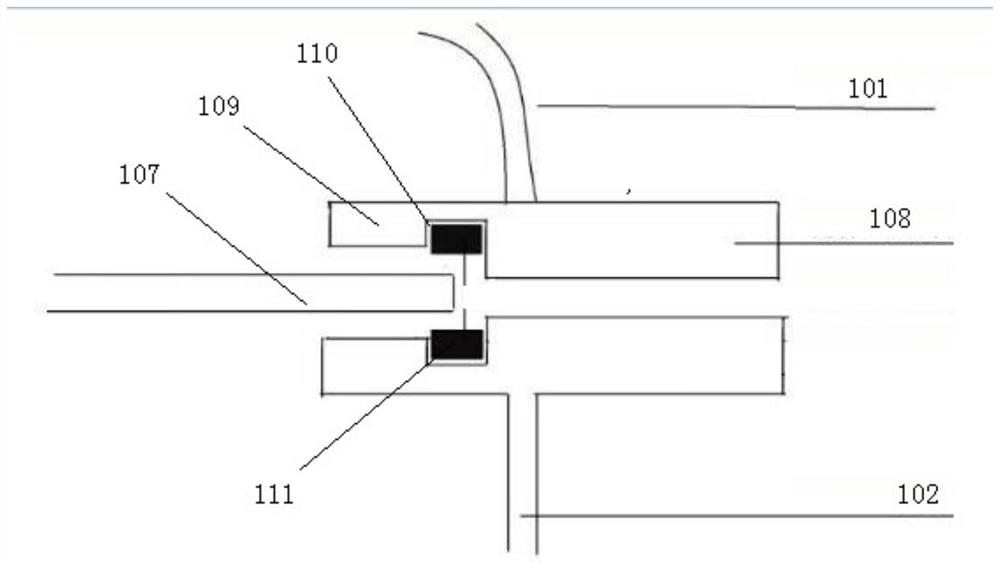

[0045] like Figure 1-7 As shown, a backwashable stainless steel tubular multi-layer sintered filter screen precision filter device includes an upper cover 101, a cylinder 102, a liquid inlet 103, a liquid outlet 105, a filter element assembly 106 and a partition 107; The upper cover 101 is arranged on the top of the cylinder 102, the liquid inlet 103 is arranged on the cylinder 102, the liquid outlet 105 is arranged on the upper cover 101, and the partition 107 is arranged on the upper cover 101 and the cylinder Between 102; the upper cover 101 and the cylinder 102 are connected by flanges, the partition 107 is provided with an opening matching the filter element assembly 106, and the filter element assembly 106 is connected to the partition 107 through the opening;

[0046] Based on the above structure, the partition 107 divides the upper cover 101 and the cylinder 102 into two different cavities, and the filtrate enters from the liquid inlet 103 of the cylinder 102. Since t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com