Feed fermentation packaging bag

A packaging bag and feed technology, which is applied in the field of packaging bags, can solve problems such as difficult heat dissipation, bag explosion, and external air entry, and achieve the effects of ensuring fermentation quality, improving heat dissipation, and avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In the following detailed disclosure, with reference to the accompanying drawings, the embodiments are fully described with reference to the accompanying drawings, which are characterized in part as illustrations of specific embodiments that can be implemented, in order to make the technical solutions of the present invention more clear and clear to those skilled in the art, The embodiments described below are not limited to this, and the present invention will be described in further detail below with reference to the embodiments and the accompanying drawings.

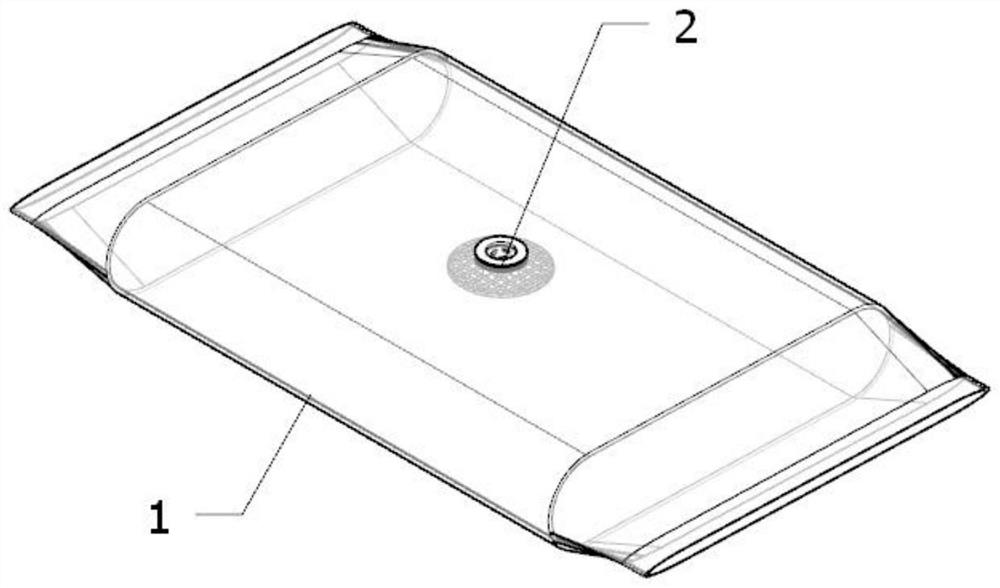

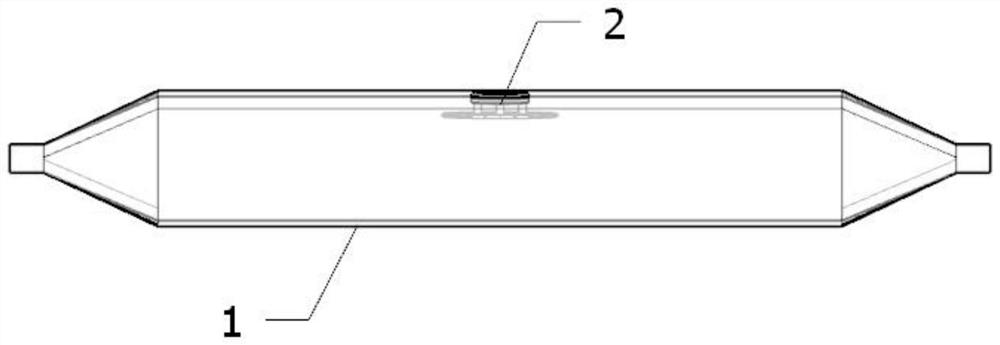

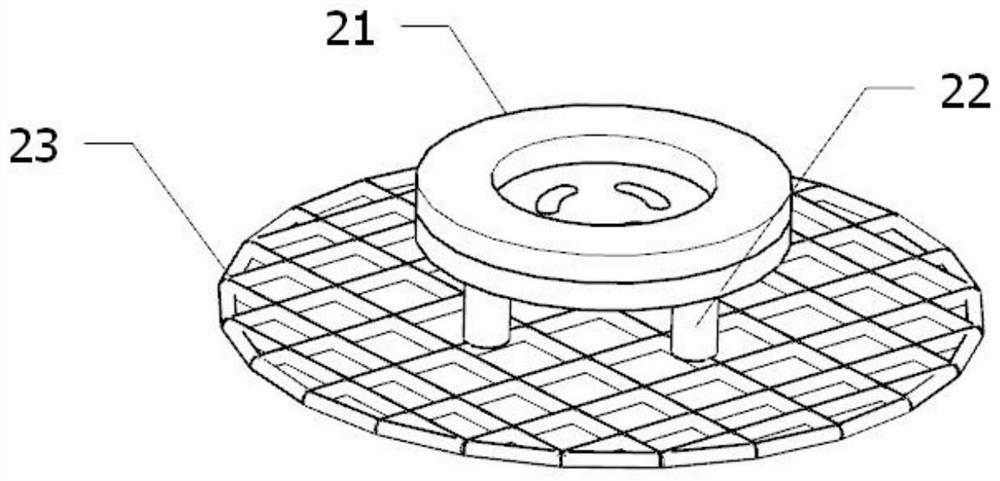

[0024] like Figure 1-Figure 3 As shown, in the embodiment, the bag body 1, the bag body 1 is an airtight plastic film, the bag body 1 is provided with a ventilation hole, the shown ventilation hole is provided with a one-way valve 2, and the one-way valve 2 includes a breathing valve 21 and the tray 23 disposed in the bag body 1 , the breathing valve 21 is provided with a plurality of pillars 22 extending into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com