Industrial multistage communicated liquid fermentation method for bacillus cereus preparation for dissolving oscillatoria in pond

A technology of Bacillus cereus and Oscillator pond, applied in the field of microbial preparations, can solve problems such as no industrialized production of inoculants, industrialized fermentation production of inoculants, etc., achieve good dissolution specificity, and ensure high purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

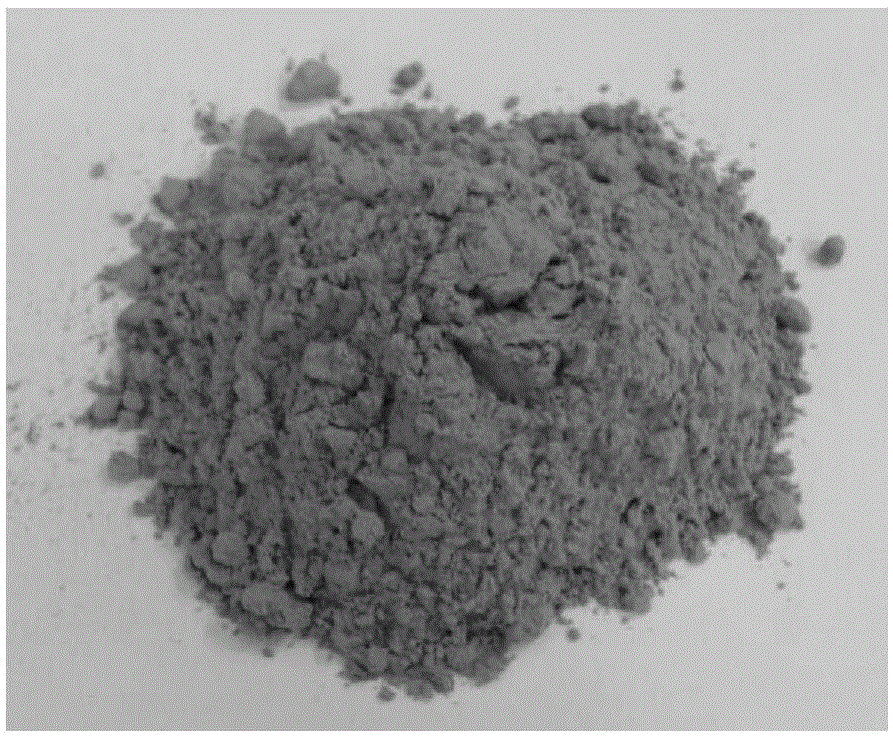

Image

Examples

Embodiment 1

[0046] The industrialized multi-stage connected liquid fermentation method of the Bacillus cereus preparation provided in this embodiment comprises the following steps:

[0047] (1) Establishment of industrialized liquid fermentation parameters of bacterial agents

[0048] The 50L primary fermentation tank system platform was used to study and establish the process parameters of the industrialized liquid fermentation of bacterial agents. Taking the spore formation rate of Bacillus cereus CZBC1, the algae-lysis efficiency and effect time of inoculant fermentation products as the core indicators, the relevant fermentation parameters were established and optimized.

[0049] First, using the single factor test method, on the basis of the basic fermentation medium, different carbon sources (glucose, sucrose, glucose+sucrose, soluble starch, molasses, corn steep liquor, cornstarch, bran, bran+molasses, Soluble starch + corn steep liquor), different nitrogen sources (peptone, yeast ...

Embodiment 2

[0067] The industrialized multi-stage connected liquid fermentation method of the Bacillus cereus preparation provided in this embodiment comprises the following steps:

[0068] Production and application were carried out in the Huadu Microbial Industrial Fermentation Experimental Factory of the South China Sea Fisheries Research Institute of the Chinese Academy of Fishery Sciences in Huadu District, Guangzhou City and Guangzhou Xinhai Lisheng Biotechnology Co., Ltd. The fermentation system is a multi-stage fermentation system of 50L-500L-5000L Unicom fermentation system.

[0069] (1) First prepare the seed liquid of CZBC1 bacterial strain in the laboratory, and the preparation method of the seed liquid of CZBC1 bacterial strain is the same as that in Example 1.

[0070] (2) The formula of the fermentation medium is 7.5g of glucose, 7.5g of molasses, 5g of yeast extract, 5g of peptone, 20g of soybean protein, 1g of NaCl, KH in 1L of water 2 PO 4 0.2g and MgSO 4 0.2g, accord...

Embodiment 3

[0077] The difference from Example 2 is that the fermentation medium formula contains 0.6g of glucose, 8.5g of molasses, 5g of yeast extract, 7g of peptone, 18g of soybean protein, 1.3g of NaCl, and KH in 1L of water. 2 PO 4 0.15g and MgSO 4 0.3g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com