Method for producing modified bentonite by using urea-chitosan

A technology of bentonite and chitosan, applied in chemical instruments and methods, other chemical processes, etc., can solve problems such as additional pollution costs, and achieve the effects of good fixation effect, good application prospect and obvious removal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method utilizing urea-chitosan to produce modified bentonite comprises the following specific steps:

[0026] (1) Take 2g urea and join in 50g bentonite and stir and grind, add water 500g to make bentonite suspension;

[0027] (2) Weighing 5g of chitosan, adding 500ml of acetic acid solution with a mass fraction of 1.0-3.0% for dissolving, to obtain chitosan-acetic acid solution.

[0028] (3) Slowly add the chitosan acetic acid solution obtained in step (2) to the bentonite suspension obtained in step (1) in a water bath at 80°C, and continue to bathe in water for 2 hours at a temperature of 80°C. , cooled to room temperature, filtered, washed the filter cake 5 times, and dried the resulting filter cake in an oven at 80°C for 24 hours; then ground it and passed it through a 200-mesh sieve to obtain modified bentonite.

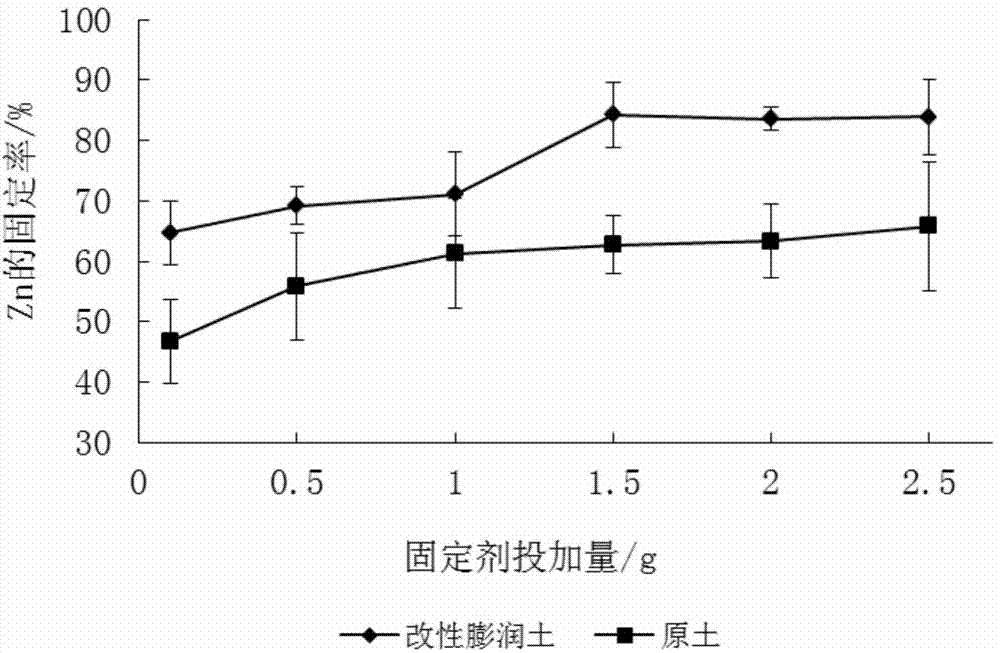

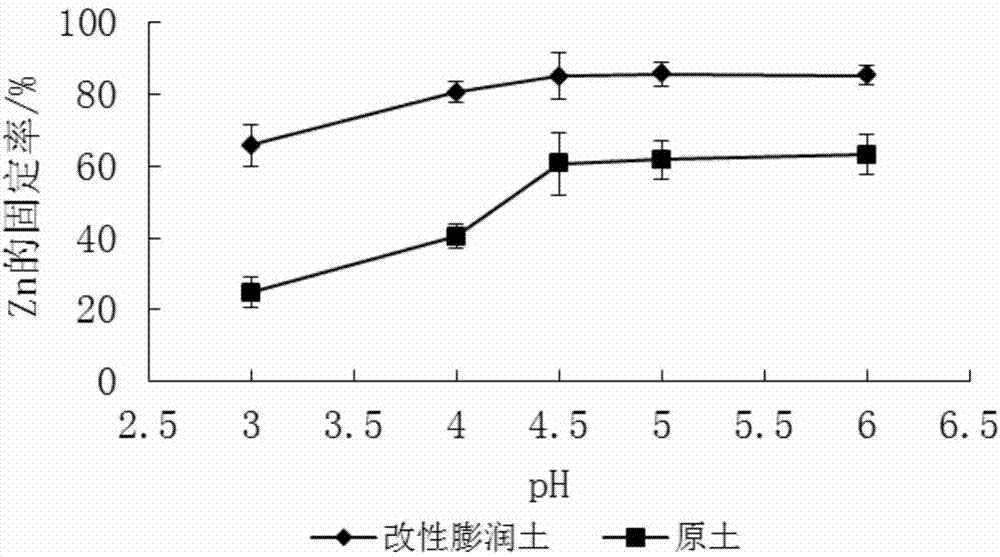

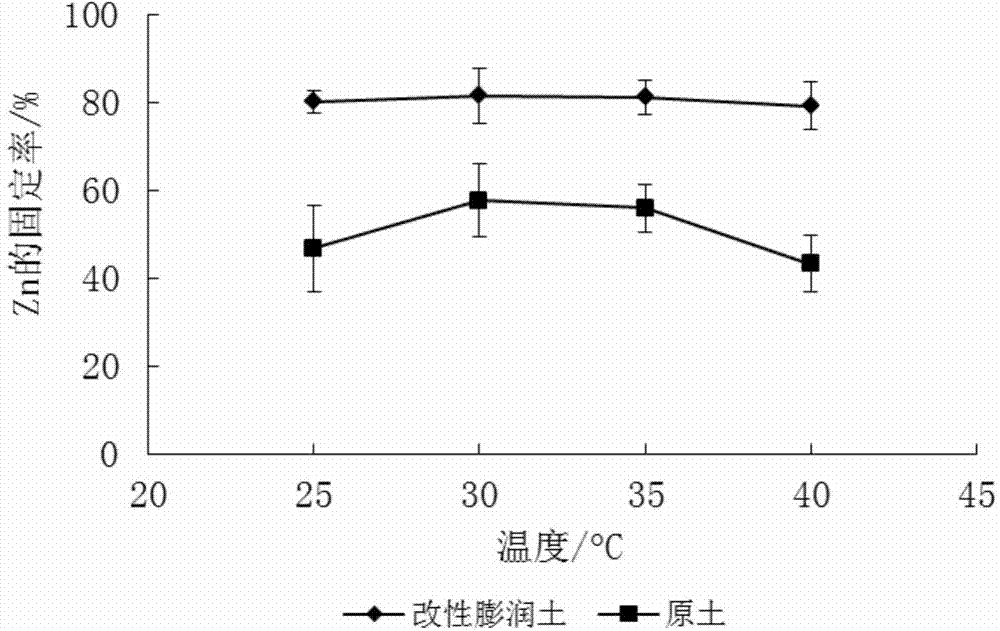

[0029] 1. the original soil and the modified bentonite obtained in Example 1 are to the comparative test of the fixation rate of zinc in the tailings...

Embodiment 2

[0038] A method utilizing urea-chitosan to produce modified bentonite comprises the following specific steps:

[0039] (1) Take by weighing 1g urea and join in 40g bentonite, stir and grind, add water 400ml to make bentonite suspension;

[0040] (2) Weigh 4.5g of chitosan, add 400ml of acetic acid solution with a mass fraction of 1.0% to dissolve, and obtain chitosan-acetic acid solution.

[0041] (3) Slowly add the chitosan acetic acid solution obtained in step (2) to the bentonite suspension obtained in step (1) in a water bath at 70°C, and continue to bathe in water for 2 hours at a temperature of 70°C. , cooled to room temperature, filtered, washed the filter cake 3 times, and dried the obtained filter cake in an oven at 70°C for 24 hours; then ground it and passed it through a 200-mesh sieve to obtain modified bentonite.

Embodiment 3

[0043] A method utilizing urea-chitosan to produce modified bentonite comprises the following specific steps:

[0044] (1) Take by weighing 3g urea and join in 55g bentonite, stir and grind, add water 550ml part and make bentonite suspension;

[0045] (2) Weigh 6.0 g of chitosan, add 550 ml of 2.5% acetic acid solution in mass fraction to dissolve, and obtain chitosan acetic acid solution.

[0046] (3) Slowly add the chitosan acetic acid solution obtained in step (2) dropwise to the bentonite suspension obtained in step (1) in a water bath at 85°C, continue the water bath at a temperature of 85°C for 2.5h, and the water bath ends Afterwards, cool to room temperature, filter, wash the filter cake with water 6 times, and dry the obtained filter cake in an oven at 85°C for 20 hours; then grind and pass through a 200-mesh sieve to obtain modified bentonite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com