TiO2 column-supporting alta-mud adsorption-photocatalysis integrated process for preparation of catalysts

A technology of bentonite and photocatalysis, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, separation methods, etc., can solve the problems of slow mineralization rate of organic matter, influence of photocatalytic effect, easy condensation of wastewater treatment, etc. Convenience, easy control, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The preparation principle of the present invention is:

[0017] The present invention uses butyl titanate as a reaction reagent and ethanol as a solvent. Under the condition of neutral pH, butyl titanate will undergo hydrolysis and polycondensation reaction with trace moisture in the air. Its reaction equation is as follows:

[0018] The hydrolysis reaction of titanium alcoholate is Ti-OR+H 2 O→Ti-OH+R-OH

[0019] Dehydration polycondensation-Ti-OH+HO-Ti-→-Ti-O-Ti-+H 2 o

[0020] Loss of alcohol polycondensation-Ti-OR+HO-Ti-→-Ti-O-Ti-+ROH

[0021] The main component of bentonite is montmorillonite. Montmorillonite is a layered silicate mineral of 2:1 type, which belongs to the monoclinic crystal system. It is one of the most notable characteristics of bentonite. Mg present in the interlayer 2+ , Ca 2+ 、Na + 、K + 、H + , Li + etc., can replace each other under certain conditions. Generally in suspension, cations of higher concentration can exchange for catio...

Embodiment 1

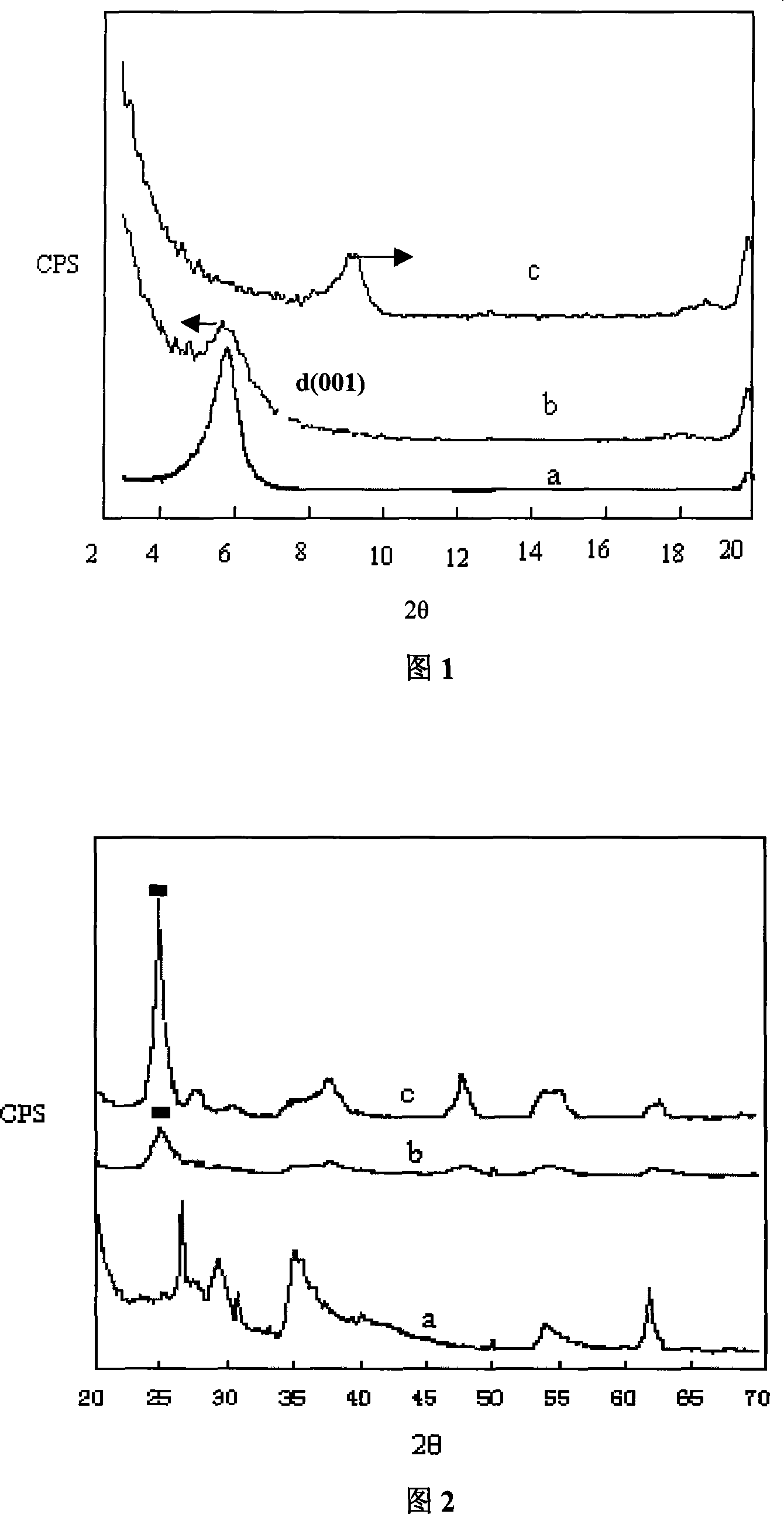

[0023] The nano-titanium dioxide pillared bentonite of the present invention is a kind of porous composite material obtained by inserting nano-sized titanium dioxide particles between bentonite layers, and has the function of integrating adsorption-photocatalysis to degrade organic matter in waste water and waste gas.

[0024] The preparation method of nano titanium dioxide pillared bentonite of the present embodiment is as follows:

[0025] 1) Add butyl titanate to absolute ethanol, the molar ratio of absolute ethanol to butyl titanate is 3.6:1, stir for 1.5h, and the stirring speed is 140rpm, to form a transparent light yellow sol A, in the air Aging for 1.5h, stand-by;

[0026] 2) Take bentonite, the cation exchange capacity of the bentonite is 0.5 of the mole number of butyl titanate, after fully infiltrating with water, a suspension B of bentonite is formed, and the cation exchange capacity of the bentonite is 108mmol / 100g;

[0027] 3) Add the suspension B to the sol A a...

Embodiment 2

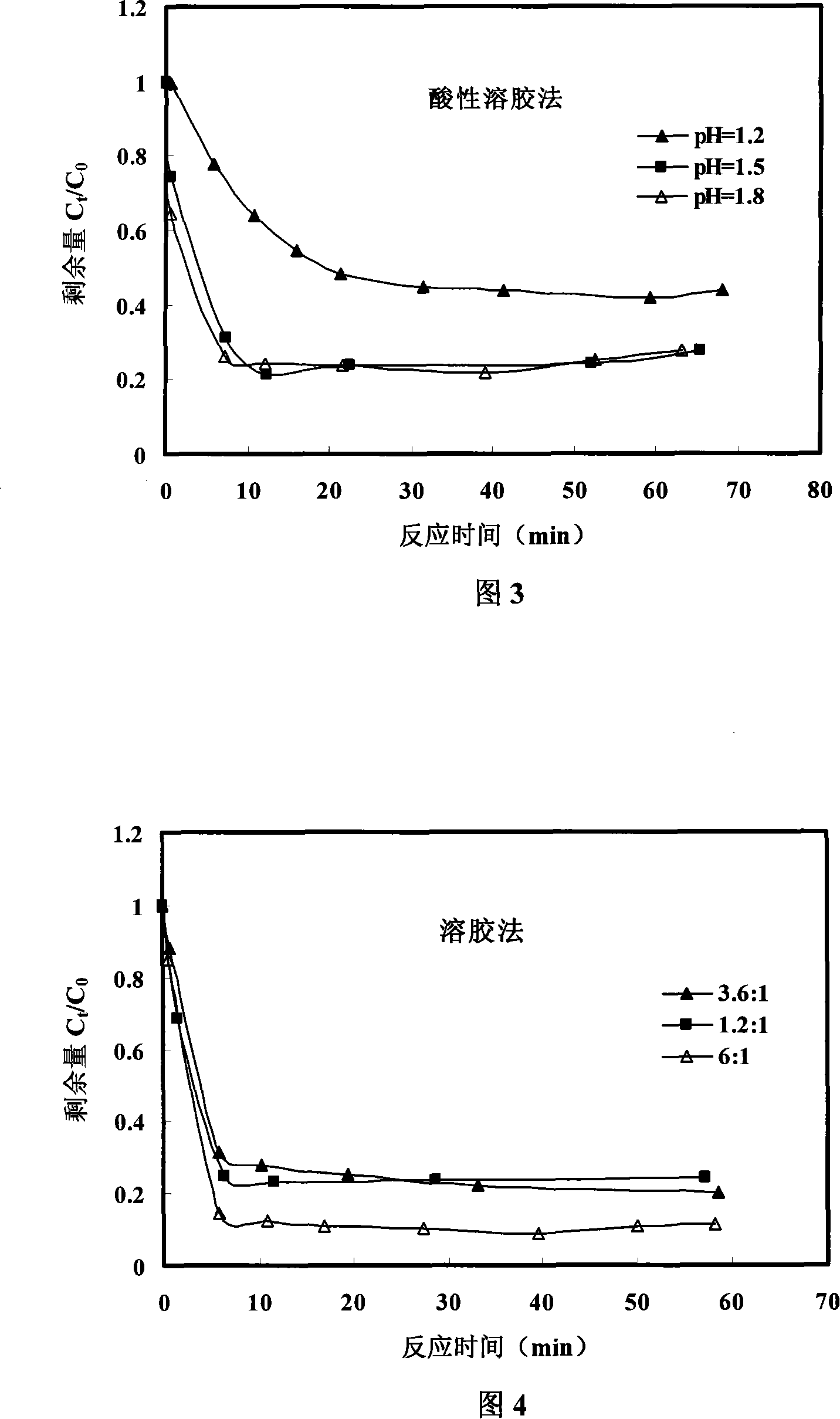

[0032] Example 2. The difference from Example 1 is that a group of ratios (I, II, III, IV, V) with different molar numbers of absolute ethanol and butyl titanate are tested, and the prepared titanium dioxide pillared bentonite of the present invention , see Table 2.

[0033] Table 2

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com