Process for preparing nano titanium dioxide bentonite composite material

A technology of nano-titanium dioxide and composite materials, which is applied in the field of preparation of catalytic materials, can solve the problems of low concentration of bentonite suspension, limitation of industrialization degree, and destruction of bentonite structure, and achieves remarkable adsorption and catalytic effects, simple and easy preparation process, and easy material extraction. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Add 100g of refined sodium-based bentonite to 9 times of distilled water to swell, shear at high speed for 20 minutes, add 0.1g of sodium silicate to modify and prepare 10wt% bentonite suspension, and set aside; 10ml of TiCl 4 Transfer to 100ml of absolute ethanol, fully stir for 1 hour, then age for 5 hours, then add to 200ml of a mixed solution of glycerol and water with a volume ratio of 1:1, stir for 2.5 hours, then age for 24 hours, mix the aging solution with 200ml of 10wt% bentonite suspension was mixed and fully stirred for half an hour, then moved into a polytetrafluoroethylene-lined autoclave, heated to 100°C, and kept at a constant temperature for 11 hours. After cooling, the resulting slurry was washed with deionized water until it was free of Cl - , Dry at 60°C and grind to obtain the nano-titanium dioxide bentonite composite material of the present invention.

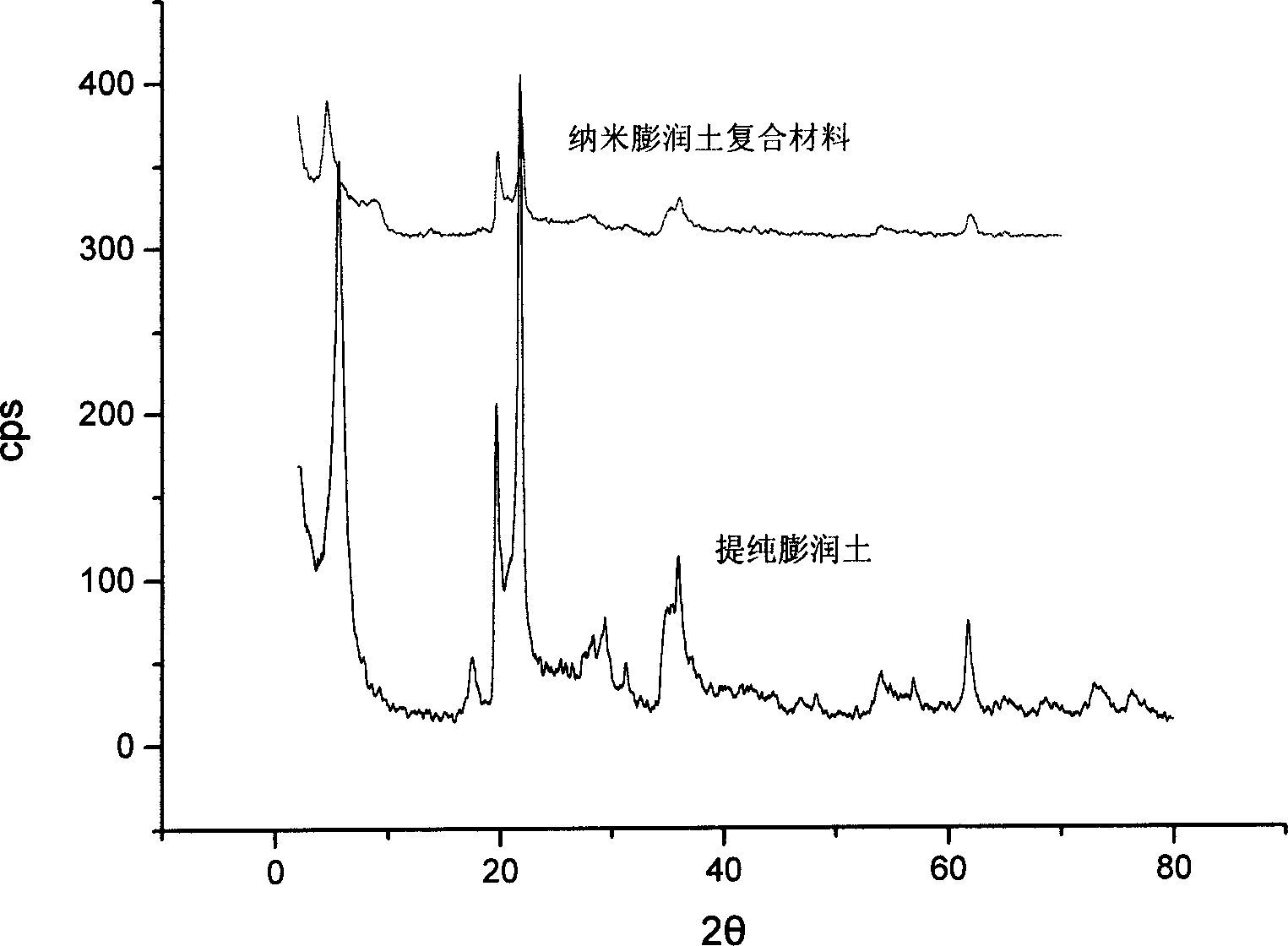

[0018] Depend on figure 1 It can be seen that the diffraction angles 2θ corresponding to both d...

Embodiment 2

[0020] Add 100g of refined calcium-based bentonite to 4 times of distilled water to swell and shear at high speed for 20 minutes, add 0.5g of sodium dodecylbenzenesulfonate to modify and prepare a 20wt% bentonite suspension, and set aside; 10ml of TiCl 4 Transfer to 100ml of absolute ethanol, stir well for 1 hour, then age for 5 hours, then add to 150ml of a mixed solution of ethylene glycol and water with a volume ratio of 2:1, stir for 3 hours, then age for 48 hours, mix the aging solution with 100ml of 20wt% bentonite suspension was mixed and fully stirred for half an hour, then moved into a polytetrafluoroethylene-lined autoclave, heated to 120°C, kept at a constant temperature for 10 hours, and the slurry obtained after cooling was washed with deionized water until it was free of Cl - , dried at 80°C and then ground to obtain the nano-titanium dioxide bentonite composite material of the present invention.

Embodiment 3

[0022] Weigh 0.1 g of the catalyst prepared in Example 1 and put it into 50 ml of 20 g / l methyl orange solution. After ultrasonic dispersion, the decolorization rate is 100% after standing for 1 hour under sunlight with an average sunlight intensity of 7654 lux.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com