Black oxygen-deficient bismuth oxide and preparation method thereof, and rare earth metal doped oxygen-deficient bismuth oxide photocatalytic material and preparation method thereof

A technology of photocatalytic materials and rare earth metals, applied in the field of photocatalysis, can solve problems such as poor light absorption efficiency, easy recombination of photogenerated electrons and holes, application limitations, etc., and achieve high-efficiency absorption enhancement, significant adsorption capacity and removal effect, and high photocatalysis performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

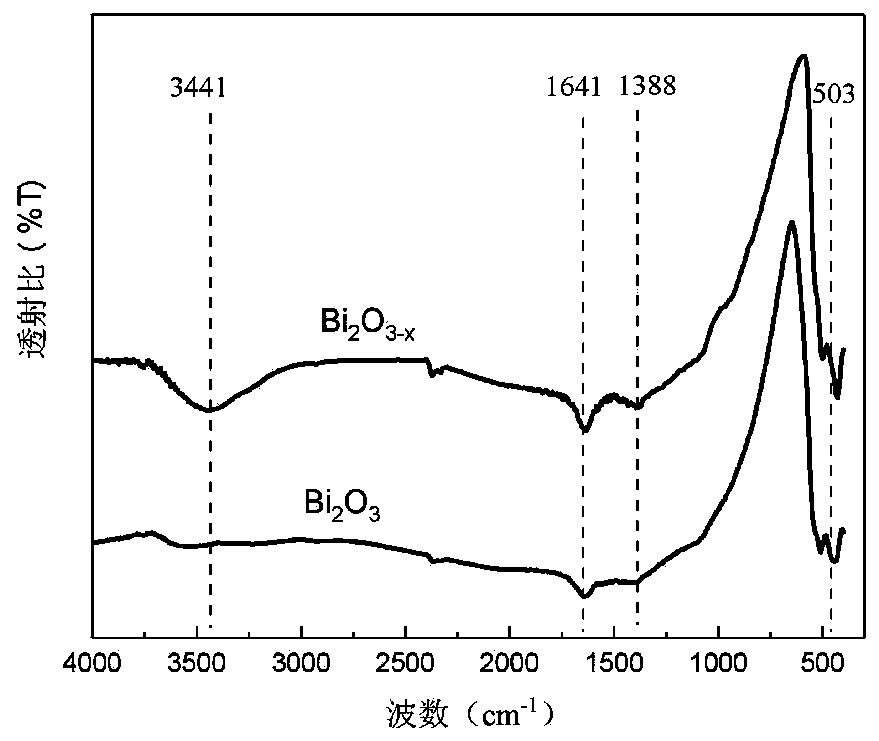

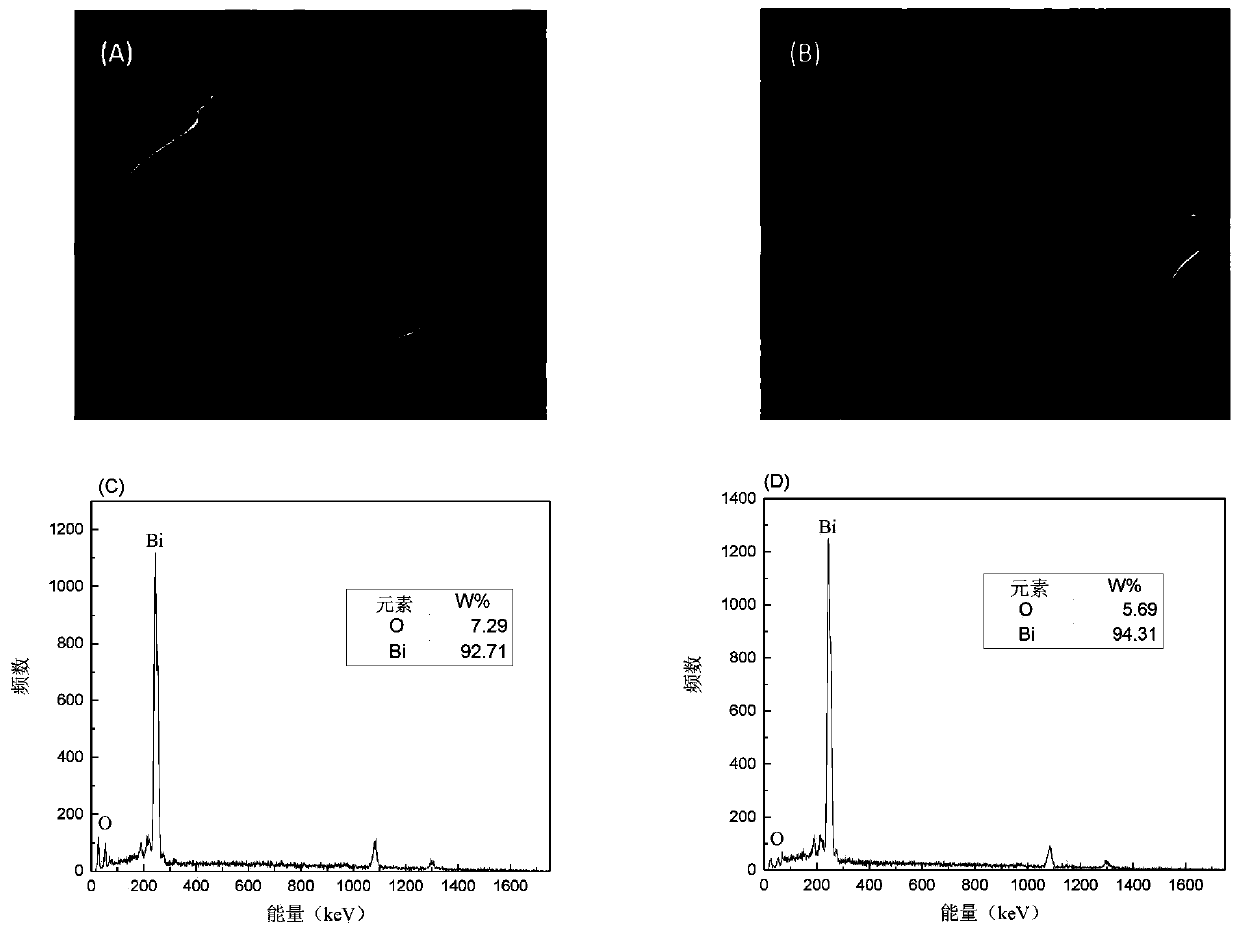

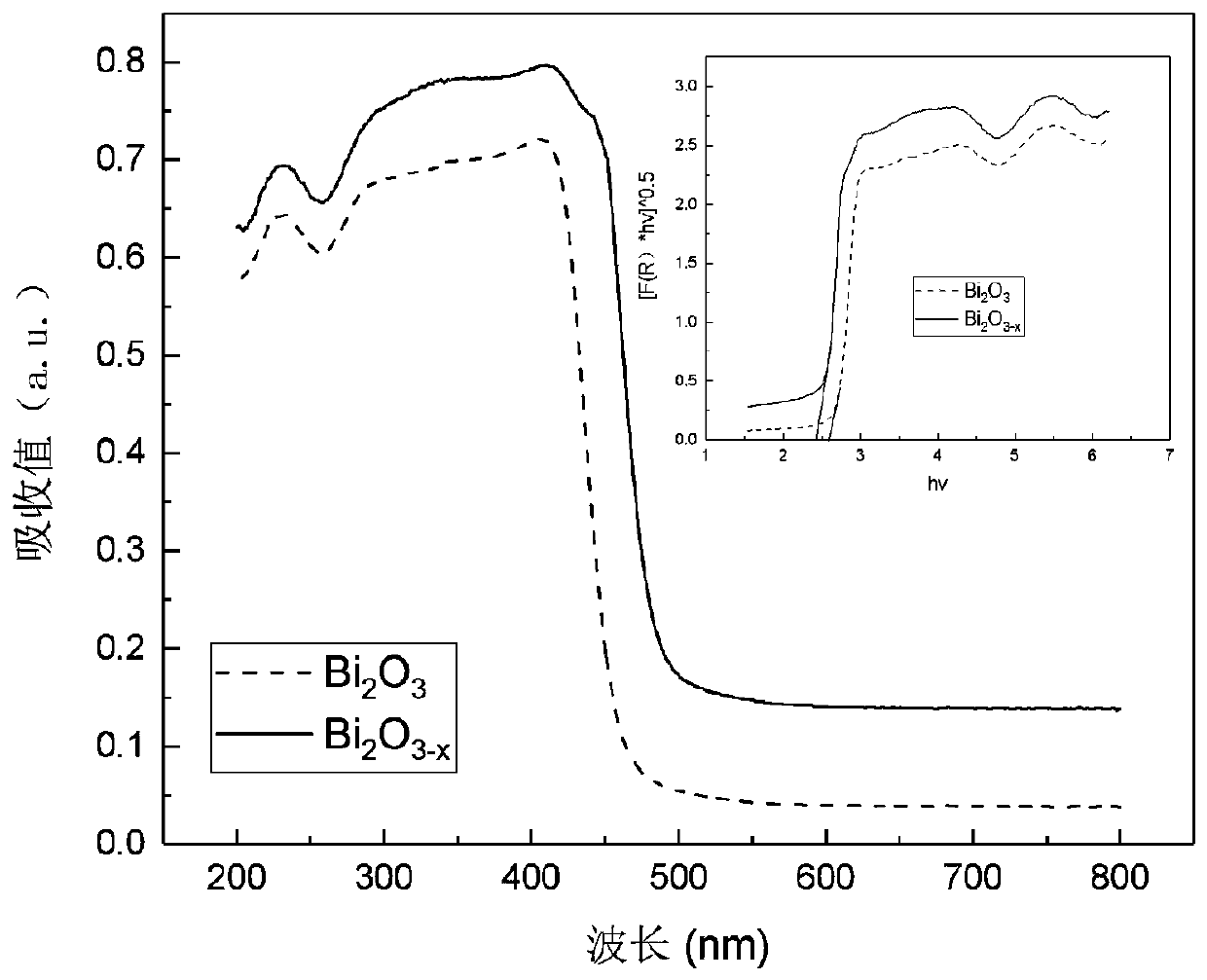

[0042] Example 1 Preparation of black oxygen-deficient bismuth oxide

[0043] 1. Preparation of bismuth oxide base material

[0044] (1) Take by weighing bismuth nitrate pentahydrate 4.85g, put into beaker;

[0045] (2) Add 100mL ultrapure water;

[0046] (3) 125 microliters of concentrated nitric acid of 65%~68% were added dropwise, stirred evenly, and the solution was clarified;

[0047] (4) Add 4.203g of citric acid monohydrate, 7.108g of acrylamide and 20.180g of glucose, and stir with ultrasound for 10min to form a homogeneous solution;

[0048] (5) Heating in a water bath at 95°C and keeping the polymerization reaction for 15 minutes;

[0049] (6) Cool the gel to precipitate and separate, and wash with ultrapure water for 3 to 5 times;

[0050] (7) The obtained powder was dried at 80° C. for 8 hours;

[0051] (8) Carry out calcination at last, and the heating program is, heat up to 300 DEG C from 25 DEG C through 275 min, keep warm for 60 min, heat up to 600 DEG C t...

Embodiment 2

[0076] Embodiment 2 dipping method prepares the black bismuth oxide of La, Ce, Er doping

[0077] One, prepare the black bismuth oxide of La doping, operate according to the following steps:

[0078] (1) preparation concentration is the aqueous solution of lanthanum nitrate hexahydrate of 216.51g / L;

[0079] (2) Get a corundum boat, add 100 microliters of the above-mentioned aqueous solution of lanthanum nitrate hexahydrate dropwise therein, and then add 100 microliters of ultrapure water;

[0080] (3) Sample 1 oxygen-deficient black Bi prepared in Example 1 was weighed 2 o 3-x Add 0.5g into the above corundum boat and stir rapidly;

[0081] (4) Stir for 6 minutes and then soak for 3 minutes, stir again for 6 minutes and then soak for 3 minutes. Repeat this process until the total time reaches 90 minutes;

[0082](5) Put it into a vacuum drying oven (vacuumize 0.1Pa) and dry at 80°C for 6h;

[0083] (6) Put the dried La-doped black bismuth oxide into the tube furnace to e...

Embodiment 3

[0104] The photocatalytic removal effect of embodiment 3 methyl orange

[0105] (1) Take by weighing respectively 0.2g of the following photocatalytic materials (prepared in Examples 1 and 2): Bi 2 o 3-x 、 Bi 2 o 3 、La / Bi 2 o 3-x 、Ce / Bi 2 o 3-x and Er / Bi 2 o 3-x ;

[0106] (2) Add 100mL of 10mg / L methyl orange (MO) solution respectively, and the initial test pH of the degradation solution is about 7.0;

[0107] (3) Prepare five 1000mL glass containers, put the suspension solution of step (2) into the glass containers respectively, and stir magnetically for 30min under dark conditions, so that the MO and the photocatalytic material reach the adsorption-desorption equilibrium. Water cooling, so that the temperature of the entire reaction during the experiment does not exceed 30 ° C;

[0108] (4) Then use a 500W xenon lamp to simulate the sunlight light source (in order to obtain strict visible light in the experiment), and use a filter (420<λ<800nm) to irradiate the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com