Preparation method of La-Fe/CTMAB (cetyltrimethylammonium bromide) composite modified bentonite adsorbing material

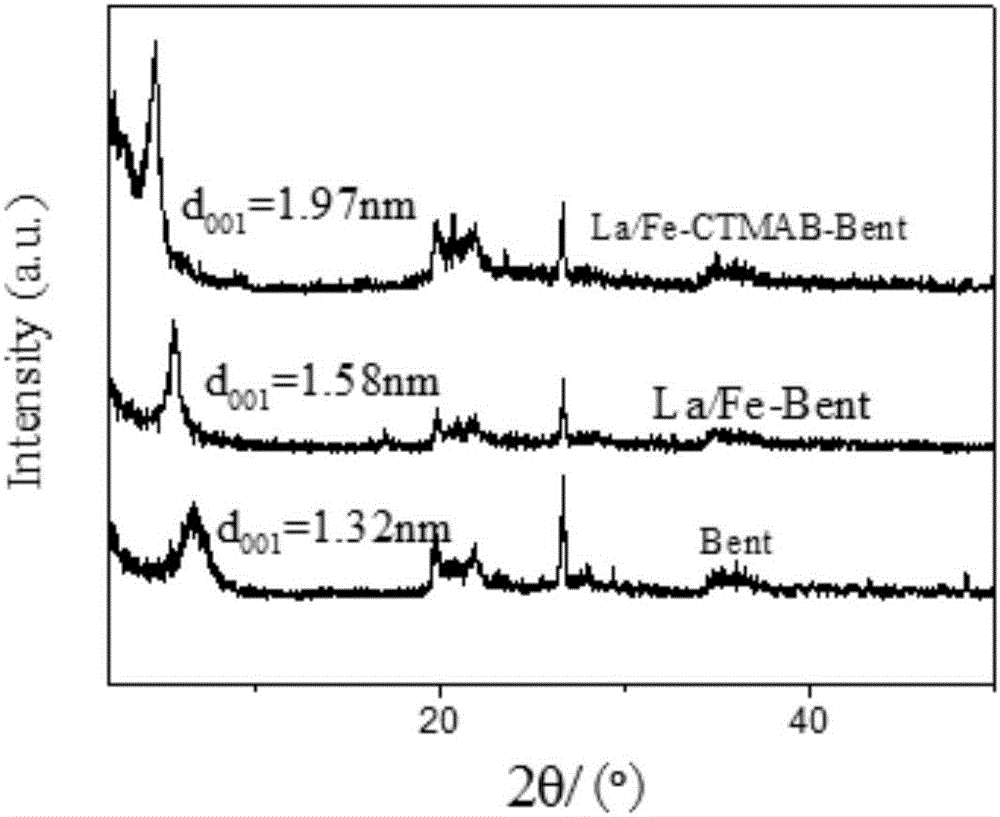

A technology of composite modification and adsorption materials, which is applied in chemical instruments and methods, adsorption water/sewage treatment, water/sewage treatment, etc., can solve the problems of poor adsorption performance of organic pollutants, and achieve high stability and increased interlayer spacing. The effect of large and large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A kind of preparation method of La-Fe / CTMAB composite modified bentonite adsorption material of the present invention, specifically implement according to the following steps:

[0053] Step 1, preparing polyhydroxyferric iron solution, denoted as solution a, specifically:

[0054] Step (1.1), configure the FeCl of 0.1mol / L 3 solution and 1mol / L NaOH solution;

[0055] Step (1.2), the 1mol / L NaOH solution that is prepared in the step (1.1) is added the FeCl of 0.1mol / L 3 Solution, stirring while adding dropwise, according to the ratio that the molar ratio of OH / Fe is 2.0, prepare polyhydroxyferric solution;

[0056] Step (1.3), stirring and aging the polyhydroxyferric solution obtained in step (1.2) to obtain a brown transparent polyhydroxyferric solution a, wherein, when stirring the polyhydroxyferric solution a, the water temperature is controlled to be 40° C., and the stirring time is 2h, the aging time is 24h;

[0057] Step 2, prepare La(NO 3 ) 3 solution, deno...

Embodiment 2

[0066] A kind of preparation method of La-Fe / CTMAB composite modified bentonite adsorption material of the present invention, specifically implement according to the following steps:

[0067] Step 1, preparing polyhydroxyferric iron solution, denoted as solution a, specifically:

[0068] Step (1.1), configure the FeCl of 0.1mol / L 3 solution and 1mol / L NaOH solution;

[0069] Step (1.2), the 1mol / L NaOH solution that is prepared in the step (1.1) is added the FeCl of 0.1mol / L 3 Solution, stirring while adding dropwise, according to the ratio that the molar ratio of OH / Fe is 2.0, prepare polyhydroxyferric solution;

[0070] Step (1.3), stirring and aging the polyhydroxyferric solution obtained in step (1.2) to obtain a brown transparent polyhydroxyferric solution a, wherein, when stirring the polyhydroxyferric solution a, the water temperature is controlled to be 80° C., and the stirring time is 2h, the aging time is 24h;

[0071] Step 2, prepare La(NO 3 ) 3 solution, deno...

Embodiment 3

[0080] A kind of preparation method of La-Fe / CTMAB composite modified bentonite adsorption material of the present invention, specifically implement according to the following steps:

[0081] Step 1, preparing polyhydroxyferric iron solution, denoted as solution a, specifically:

[0082] Step (1.1), configure the FeCl of 0.1mol / L 3 solution and 1mol / L NaOH solution;

[0083] Step (1.2), the 1mol / L NaOH solution that is prepared in the step (1.1) is added the FeCl of 0.1mol / L 3 Solution, stirring while adding dropwise, according to the ratio that the molar ratio of OH / Fe is 2.0, prepare polyhydroxyferric solution;

[0084] Step (1.3), stirring and aging the polyhydroxyiron solution obtained in step (1.2), obtain brown transparent polyhydroxyiron solution a, wherein, when stirring the polyhydroxyiron solution a, control the water temperature to be 60° C., and the stirring time is 2h, the aging time is 24h;

[0085] Step 2, prepare La(NO 3 ) 3 solution, denoted as solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com