Method for preparing organophilic bentonite

A technology of bentonite and sodium bentonite, applied in the field of preparation of organic bentonite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

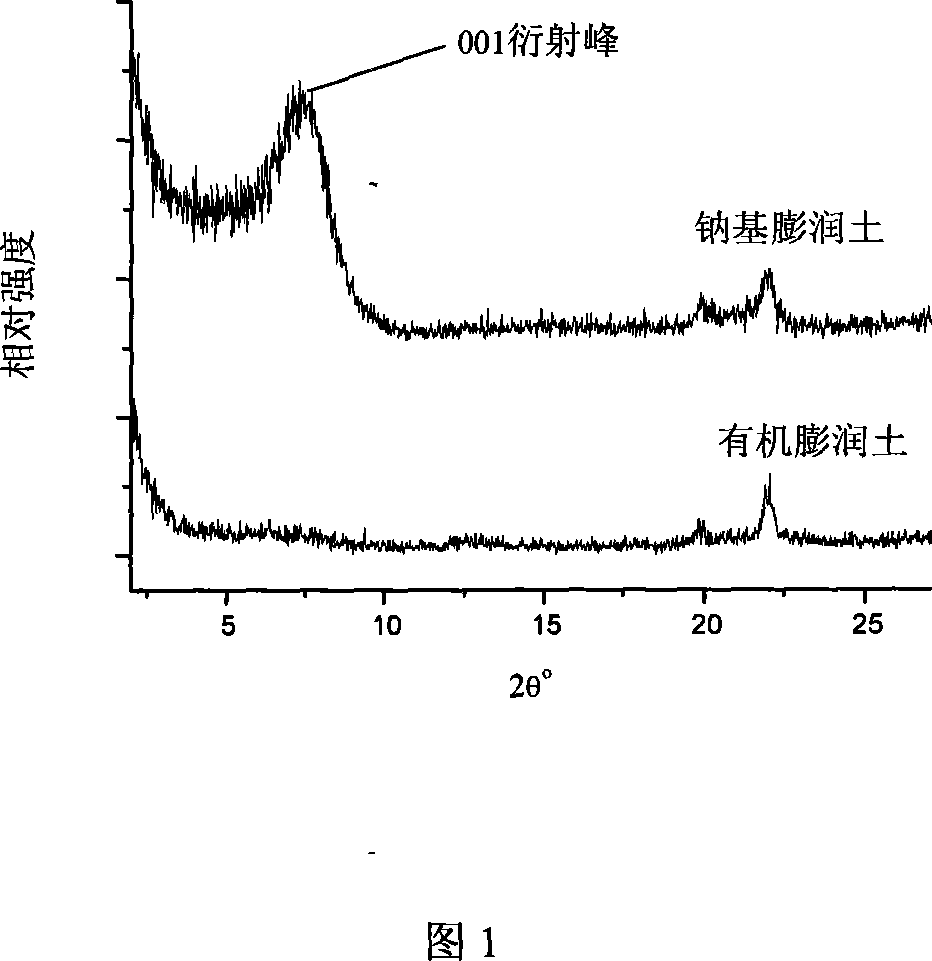

Image

Examples

Embodiment 1

[0017] Weigh 200kg of 2wt% sodium montmorillonite suspension (containing 4kg of sodium montmorillonite), add 5mol of sodium dodecylbenzenesulfonate, stir well, and add 50L of 0.1MCaCl dropwise after mixing evenly 2 (5mol) solution produces precipitation, continue to stir 1 hour, centrifuge then, take the paste of lower layer, through washing, drying, be pulverized to 200 orders, be organic montmorillonite sample, yield is 3.72kg.

Embodiment 2-4

[0019] The implementation method is the same as in Example 1, changing the concentration of sodium montmorillonite suspension, sodium dodecylbenzenesulfonate and 0.1MCaCl 2 The amount of solution used, the results are shown in the table below.

[0020] Example 2

Embodiment 5

[0022] Implementation method is the same as in Example 1, changing the anionic surfactant to be sodium lauryl sulfate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com