Composite cross-linking pole support bentonite intercalation desulfurizer and preparation method thereof

A technology of bentonite and composite cross-linking, applied in chemical instruments and methods, refined hydrocarbon oil, and other chemical processes, can solve problems such as thermal sintering at regeneration temperature, formation of zinc sulfate, reduction of zinc oxide, etc., and achieve high desulfurization accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following examples describe the present invention in more detail:

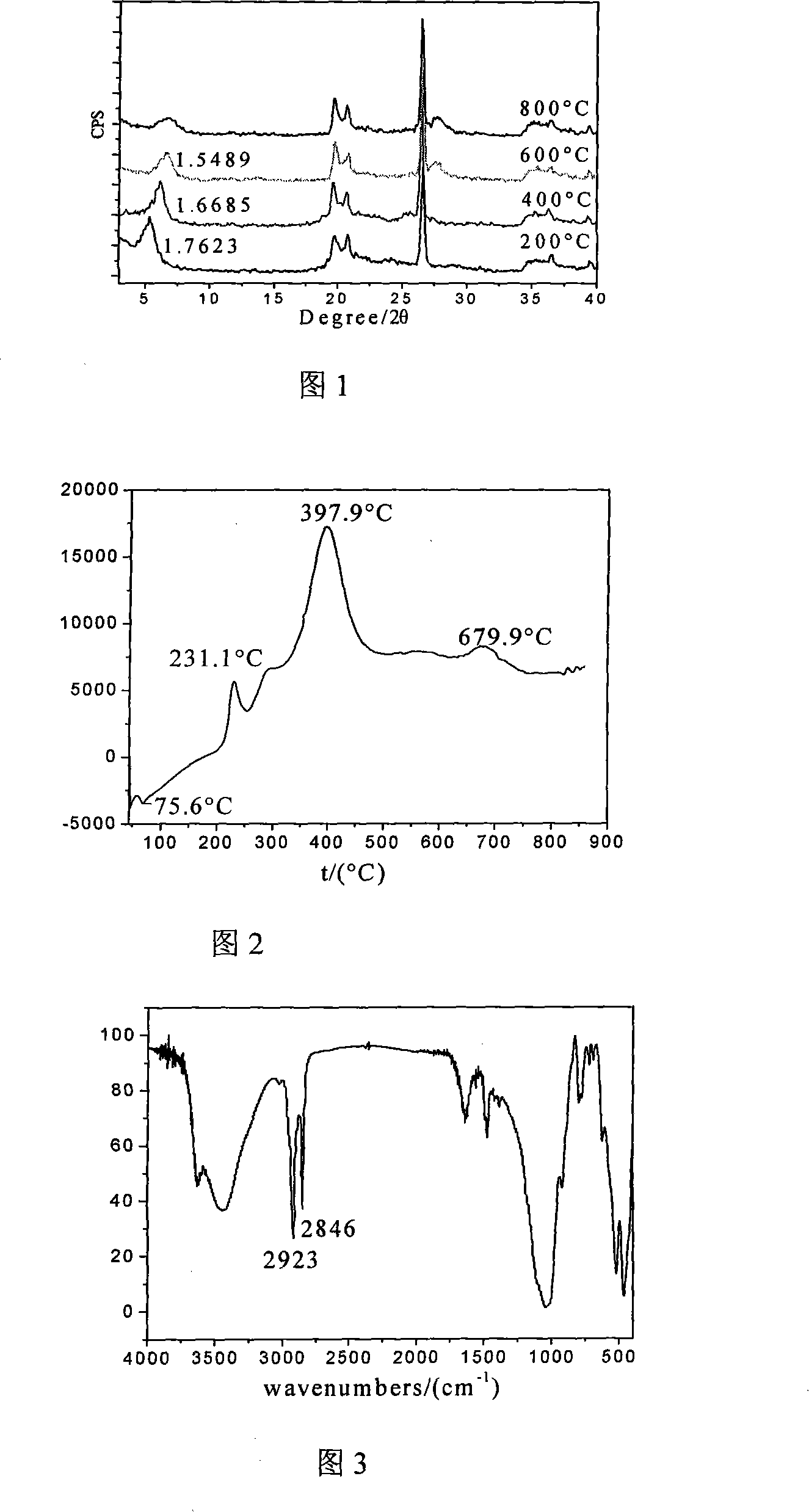

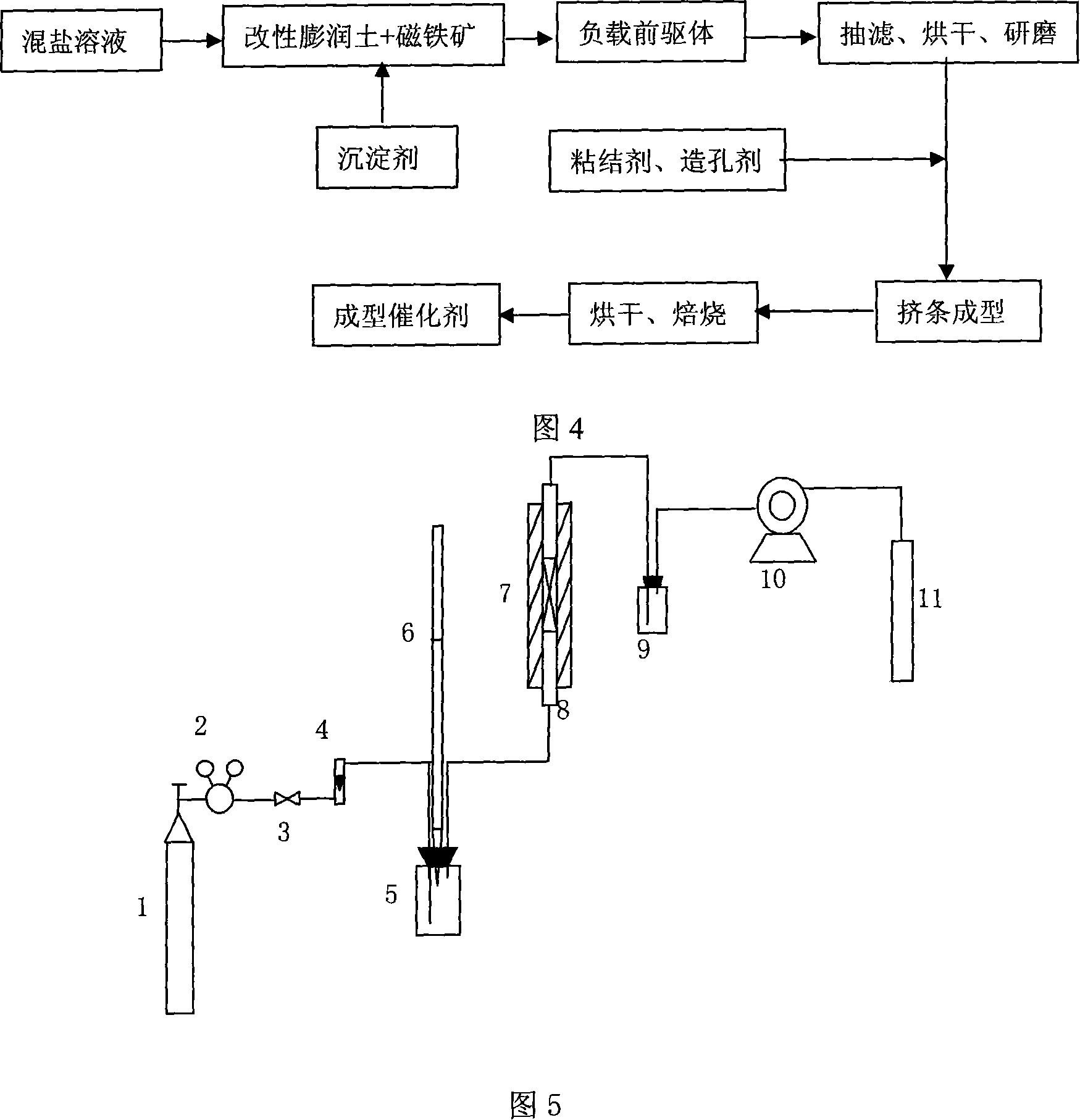

[0023]In conjunction with Fig. 4, the specific preparation method of the present invention is: use sodium pyrophosphate as a sodium modification agent, prepare a sodium conversion agent-ethanol-water solution with a mass percentage of 3% of the original soil quality, and weigh a certain amount of bentonite concentrate , to make the suspension concentration 15%, then drop the prepared solution into the bentonite fine earth suspension, stir evenly, heat to 60°C, react for 12h, after the reaction, let stand for half an hour, rinse with tap water first, Rinse again with distilled water to separate unreacted salts (using AgNO 3 Check whether the chloride ions are removed completely), the filter cake is directly put into the drying oven for drying, and the sodium bentonite is obtained after grinding.

[0024] Take sodium bentonite and prepare 100mL of slurry with a concentration of 0.01g / L under vigorous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com