Organic bentonite for composite flame retardants and preparation process thereof

A compound flame retardant and preparation process technology, applied in the treatment of dyed low molecular organic compounds, fibrous fillers, etc., can solve the problems of improved flame retardancy of organic bentonite, high degree of organic bentonite, and high cost, and achieve good flame retardancy. performance, good dispersion, good flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

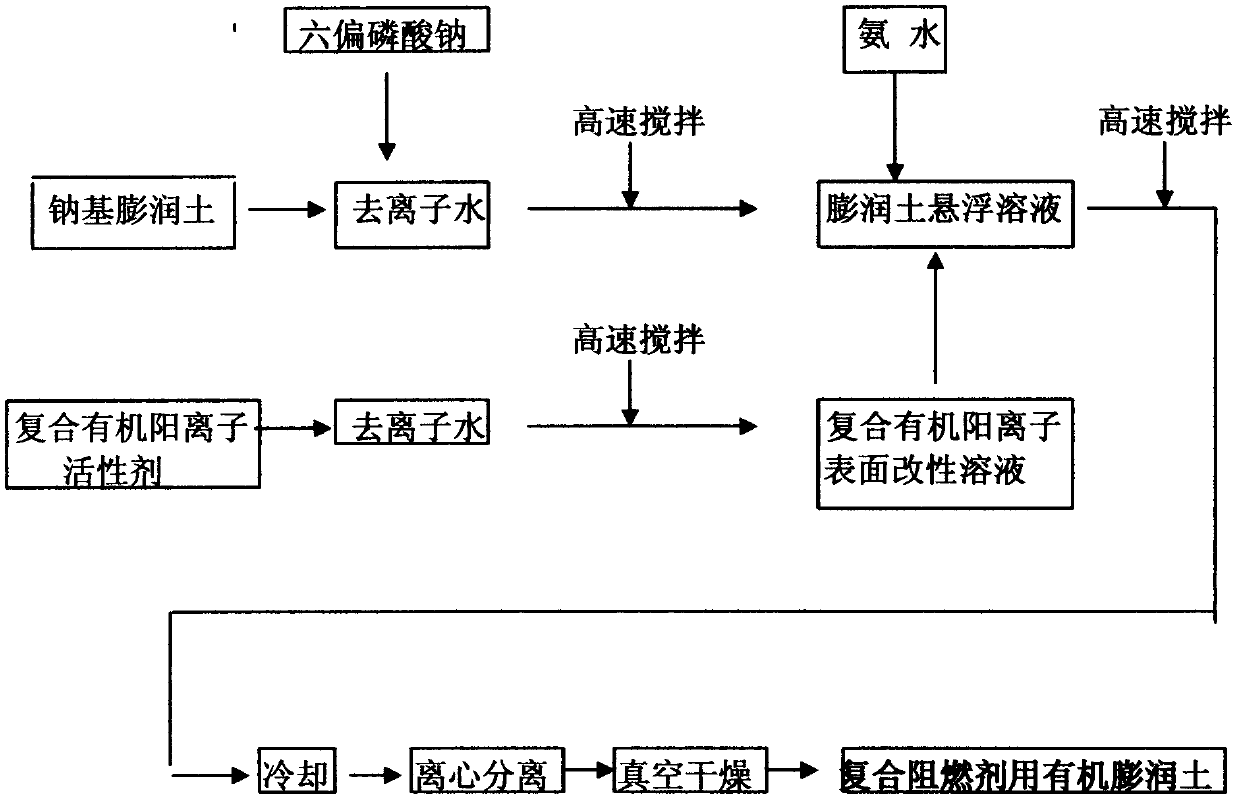

[0014] Add 3 parts of sodium hexametaphosphate to 500 parts of deionized water, and then add 50 parts of sodium bentonite, and prepare 2 bentonite suspension by high-speed stirring; combine 10 parts of Cyagard RF-1 and 10 parts of cetyltrimethyl Ammonia bromide was added to 200 parts of deionized water and stirred at high speed to obtain a composite organic cation surface modifier solution; the composite cation modifier solution was added to the bentonite suspension under high-speed stirring, and the pH of the solution was adjusted with ammonia It is 8, react at 75°C for 2 hours, stand and cool to normal temperature, centrifuge the lower sediment and place it at 80°C for vacuum drying, and crush to obtain organic bentonite.

[0015] After testing, the performance indicators of the obtained organic bentonite are as follows: density 1.78g / cm 3 , The whiteness is 85%, the moisture content is 2.7%, and the interlayer spacing is 2.685nm.

Embodiment 2

[0017] The implementation method is the same as in Example 1, changing the adding amount of sodium hexametaphosphate to 4 parts, and adjusting the pH to 9.

Embodiment 3

[0019] Add 3 parts of sodium hexametaphosphate to 500 parts of deionized water, and then add 50 parts of sodium bentonite, and stir at high speed to prepare a bentonite suspension; mix 12 parts of Cyagard RF-1 and 8 parts of cetyltrimethyl bromide Ammonia was added to 200 parts of deionized water and stirred at high speed to obtain a composite cationic surface modifier solution; the composite cationic modifier solution was added to the bentonite suspension under high-speed stirring, and the pH of the solution was adjusted to 8 with ammonia , React at a temperature of 75°C for 2 hours, stand and cool to room temperature, centrifuge the lower layer of the precipitate and place it at 80°C for vacuum drying, and crush to obtain organic bentonite.

[0020] After testing, the performance indicators of the obtained organic bentonite are as follows: density 1.72g / cm 3 , The whiteness is 83%, the moisture content is 2.8%, and the interlayer spacing is 2.425nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Layer spacing | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com