Organic modified granular bentonite/attapulgite absorbent and preparation method thereof

A technology of attapulgite and bentonite, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problems of low strength of granular bentonite, affecting the application of granular bentonite, weak adsorption capacity of pollutants, etc. To achieve the effect of good adsorption performance, large particle size and large particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

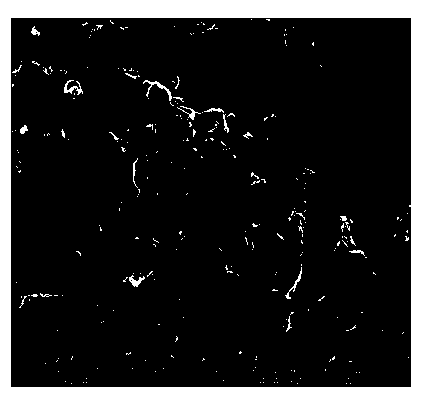

Image

Examples

Embodiment 1

[0028] An organically modified granular bentonite / attapulgite adsorbent and a preparation method thereof. Its specific steps are:

[0029] Step 1, using bentonite powder and attapulgite powder as raw materials, mixing to obtain powdery bentonite / attapulgite; then adding water to the powdery bentonite / attapulgite, and mixing evenly to obtain muddy lump bentonite / attapulgite; Then, the mud-shaped bentonite / attapulgite is dried for 16-20 hours under the condition of 105-110° C. to obtain the block-shaped bentonite / attapulgite.

[0030] Among them: the mass ratio of bentonite powder: attapulgite powder is 1: (0.1~0.2); the mass ratio of powdered bentonite / attapulgite: water is 1: (1.8~2).

[0031] Step 2, crushing the massive bentonite / attapulgite to a particle size of 0.9-2mm to obtain granular bentonite / attapulgite, and then calcining the granular bentonite / attapulgite at 750-850°C for 2-2.5 h, obtained calcined granular bentonite / attapulgite.

[0032] Step 3, under the condi...

Embodiment 2

[0037] An organically modified granular bentonite / attapulgite adsorbent and a preparation method thereof. Its specific steps are:

[0038] Step 1, using bentonite powder and attapulgite powder as raw materials, mixing to obtain powdery bentonite / attapulgite; then adding water to the powdery bentonite / attapulgite, and mixing evenly to obtain muddy lump bentonite / attapulgite; Then, the mud-shaped bentonite / attapulgite is dried for 20-24 hours under the condition of 100-105° C. to obtain the block-shaped bentonite / attapulgite.

[0039] Among them: the mass ratio of bentonite powder: attapulgite powder is 1: (0.2~0.3); the mass ratio of powdered bentonite / attapulgite: water is 1: (1.4~1.6).

[0040] Step 2, crushing the massive bentonite / attapulgite to a particle size of 0.45~0.9mm to obtain granular bentonite / attapulgite, and then calcining the granular bentonite / attapulgite at 650~750°C for 2~ After 2.5 hours, calcined granular bentonite / attapulgite was obtained.

[0041] Step ...

Embodiment 3

[0046] An organically modified granular bentonite / attapulgite adsorbent and a preparation method thereof. Its specific steps are:

[0047] Step 1, using bentonite powder and attapulgite powder as raw materials, mixing to obtain powdery bentonite / attapulgite; then adding water to the powdery bentonite / attapulgite, and mixing evenly to obtain muddy lump bentonite / attapulgite; Then, the mud-shaped bentonite / attapulgite is dried for 24-28 hours under the condition of 95-100° C. to obtain the block-shaped bentonite / attapulgite.

[0048] Among them: the mass ratio of bentonite powder: attapulgite powder is 1: (0.3~0.4); the mass ratio of powdered bentonite / attapulgite: water is 1: (1.6~1.8).

[0049] Step 2, crushing the massive bentonite / attapulgite to a particle size of 0.2-0.45mm to obtain granular bentonite / attapulgite, and then calcining the granular bentonite / attapulgite at 650-700°C for 2~ After 2.5 hours, calcined granular bentonite / attapulgite was obtained.

[0050] Step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com