Method for preparing ZSM-5 molecular sieves

A technology of ZSM-5 and molecular sieve, which is applied in the direction of crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminosilicate zeolite, etc., can solve the problem of synthetic molecular sieve materials that have not yet been seen from silicon-aluminum sources, and achieve the purpose of broadening the range of raw materials, Effects of improving performance and reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Using commercially available rectorite (produced by Hubei Mingliu Rectorite Co., Ltd., see Table 1 for its chemical composition) as raw material, 0.69 g was roasted in a muffle furnace at 800° C. for 2 h, and then used.

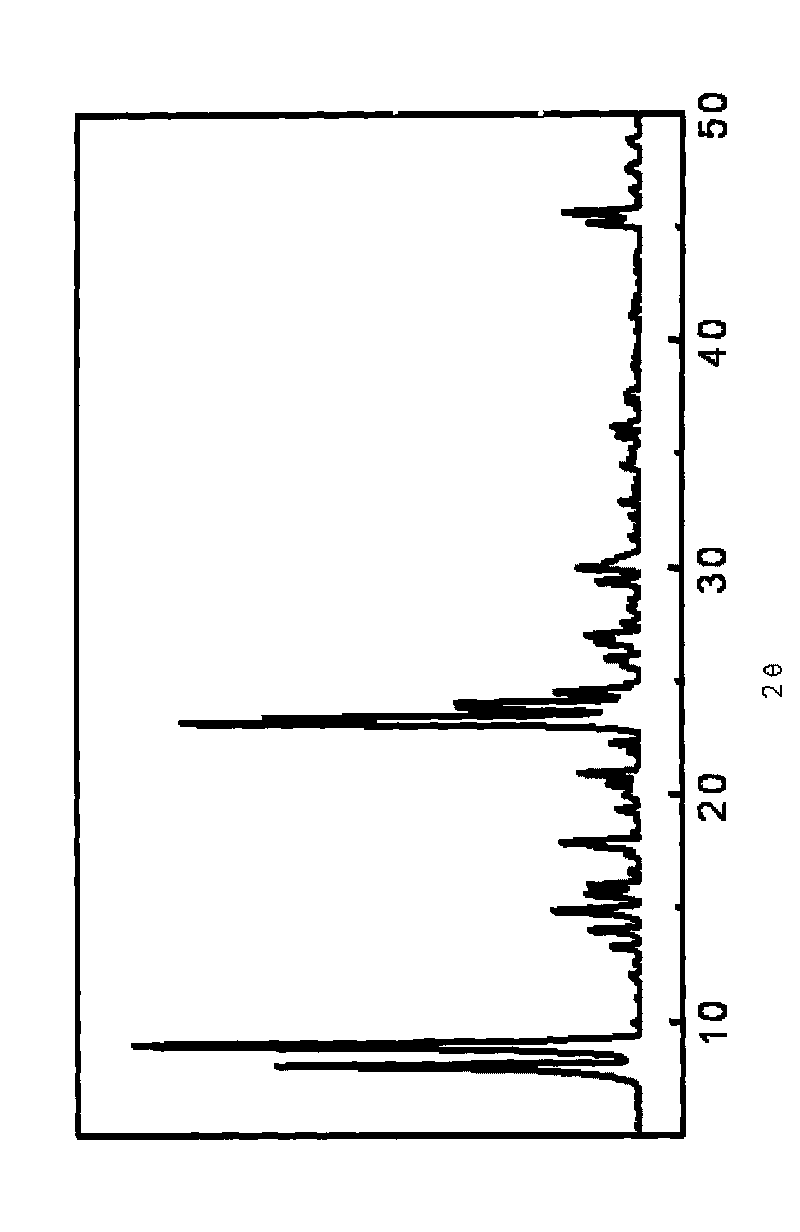

[0041] Water glass (containing SiO 2 26wt.%, Na 2 O 8wt.%) 19.7g, TPABr 2.04g, distilled water 95g, concentration is that the rectorite after the sulfuric acid aqueous solution 2.3g of 3M and roasting process joins in the beaker, mixes and stirs 1h and obtains mixture gel (this moment system pH value is about for 9). The components in the gel are calculated as oxides, and the molar ratio is SiO 2 / Al 2 o 3 ≈35, (Na 2 O+K 2 O) / SiO 2 =0.2,H 2 O / SiO 2 =70, TPABr / SiO 2 = 0.09. The mixed gel was moved into a stainless steel crystallization kettle lined with polytetrafluoroethylene, heated to 170°C, and statically crystallized for 72 hours. After the crystallization is completed, the mother liquor is removed by cooling and filtering, and then th...

Embodiment 2

[0046] Commercially available rectorite was used as raw material, and 0.9 g was calcined in a muffle furnace at 900° C. for 4 h before use.

[0047] Water glass (containing SiO 2 26wt%, Na 2 O 8wt%) 18g, TPABr 1.03g, distilled water 59g, concentration is that the sulfuric acid aqueous solution 2g of 3M and the rectorite after roasting process join in the beaker, mix and stir 1h to obtain mixture gel (this moment system pH value is about 10) . The components in the gel are calculated as oxides, and the molar ratio is SiO 2 / Al 2 o 3 ≈22, (Na 2 O+K 2 O) / SiO 2 =0.2,H 2 O / SiO 2 =50, TPABr / SiO 2 = 0.05. Move the mixture gel into a stainless steel crystallization kettle lined with polytetrafluoroethylene, raise the temperature to 175°C, and crystallize statically for 48 hours, then cool and filter to remove the mother liquor, then wash, dry, and roast at 550°C to remove the template agent A crystallized product was obtained.

[0048] According to XRD measurement, the p...

Embodiment 3

[0050] Commercially available rectorite was used as raw material, and 0.5 g was calcined in a muffle furnace at 1000° C. for 1 h, and then used.

[0051] Water glass (containing SiO 2 26wt%, Na 2 O 8wt%) 25g, TPABr 1.15g, distilled water 65g, concentration is that 3M sulfuric acid aqueous solution 2g and the rectorite after roasting process join in the beaker, mix and stir 1h to obtain mixture gel (this moment system pH value is about 10) . Each component in the gel is SiO according to its oxide molar ratio 2 / Al 2 o 3 ≈50, (Na 2 O+K 2 O) / SiO 2 =0.3,H 2 O / SiO 2 =42, TPABr / SiO 2 = 0.04. Move the mixed gel into a stainless steel crystallization kettle lined with polytetrafluoroethylene, raise the temperature to 165°C, and crystallize statically for 72 hours, then cool and filter to remove the mother liquor, then wash, dry, and roast at 550°C to remove the template agent A crystallized product was obtained.

[0052] According to XRD measurement, the phase of the pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com