Method for preparing Li-S battery anode materials by taking algae as carbon source

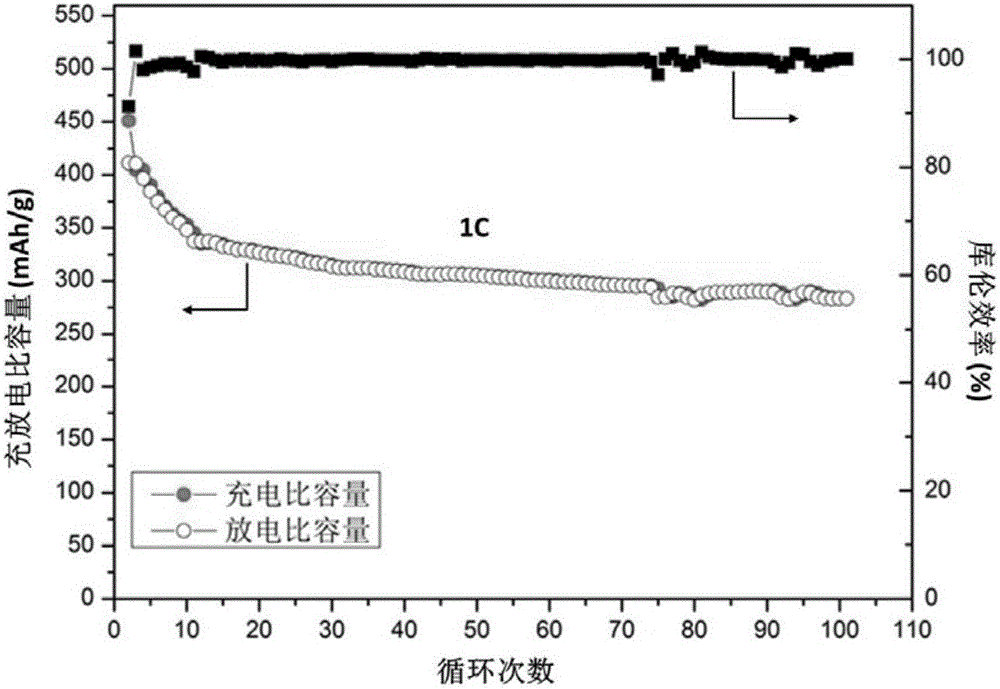

A battery positive electrode and algae technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of poor conductivity of elemental sulfur, loss of sulfur positive electrode, low battery cycle performance and coulombic efficiency, and achieve low cost, convenient material acquisition, and improved The effect of electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

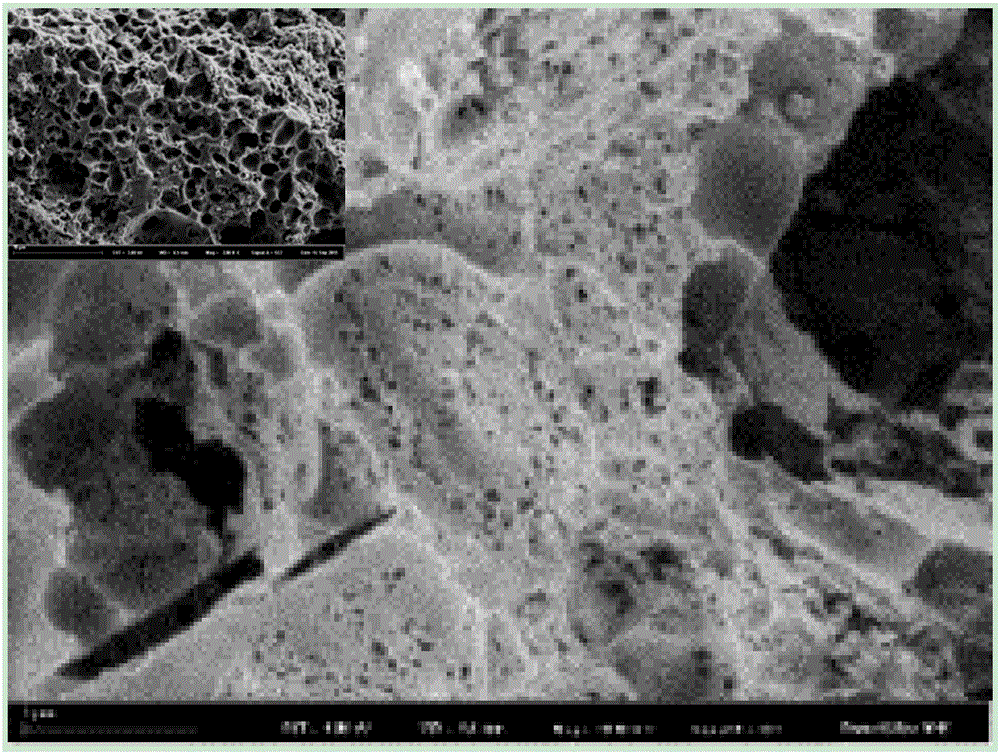

[0022] Weigh 10g of dried brown algae and dissolve it in 200ml of deionized water, and add KOH, a strong alkali substance with a purity of 99.5% of analytical purity and a mass percentage of 99.5%, at a mass ratio of 1:0.1, and stir until the brown algae is completely dissolved in water to obtain a fucoidin solution , freeze-dry it for 10 hours and then transfer it to a tube furnace. After the tube furnace is evacuated, high-purity argon gas with a mass percentage of 99.99% is introduced. The flow rate of the gas is controlled at 20ml / min. Raise the temperature of the tube furnace to 1000°C at a heating rate of 1 / min, and hold for 5 hours.

[0023] The product obtained by the above-mentioned calcination was washed repeatedly, suction filtered until the pH value was neutral, and dried at 60°C. The dried product obtained was placed in a vacuumed tube furnace, and the high Pure argon, the flow rate of the gas is controlled at 20ml / min, and the temperature of the tube furnace is r...

Embodiment 2

[0026] Weigh 15g of dried green algae and dissolve it in 450ml of deionized water, add a strong base substance KOH with a purity of 99.5% for analytical purity at a mass ratio of 1:0.5, and stir until the green algae is completely dissolved in water to obtain green algae. The alginate solution was transferred to the tube furnace after it was freeze-dried for 24 hours. After the tube furnace was evacuated, the high-purity argon gas with a mass percentage of 99.99% was introduced, and the flow rate of the gas was controlled at 30ml / min. The temperature of the tube furnace was raised to 800°C at a heating rate of 4°C / min and kept for 2h.

[0027] The product obtained by the above-mentioned calcination was repeatedly washed, suction-filtered until the pH value was neutral, and dried at 80°C. Pure argon, the gas flow rate is controlled at 30ml / min, the temperature of the tube furnace is raised to 1200°C according to the heating rate of 7°C / min, and the insulation is 3h to obtain th...

Embodiment 3

[0030] Weigh 20g of dried red algae and dissolve it in 1000ml of deionized water, add KOH, which is analytically pure and has a mass percentage of 99.5%, in a mass ratio of 1:1, and stir until the red algae is completely dissolved in water to obtain red algae. The alginate solution was transferred to the tube furnace after it was freeze-dried for 48 hours. After the tube furnace was evacuated, the high-purity argon gas with a mass percentage of 99.99% was introduced, and the flow rate of the gas was controlled at 50ml / min. The temperature of the tube furnace was increased to 500°C at a heating rate of 3°C / min and kept for 1h.

[0031] The black product obtained by the above-mentioned calcination was washed repeatedly, filtered with suction until the pH value was neutral, and dried at 100°C. High-purity argon gas, the flow rate of the gas is controlled at 50ml / min, and the temperature of the tube furnace is raised to 1400°C at a heating rate of 6°C / min, and kept for 5 hours to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com