Preparation method of microbial fertilizer

A microbial fertilizer and fermenting microorganism technology, which is applied in the field of microorganisms, can solve the problems of small number of effective bacteria, high cost of carrier and sterilization, and difficulty in collection, so as to achieve the effect of broadening the range of raw materials, improving the utilization value, and reducing the content of miscellaneous bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0020] The first embodiment: Using biomass power plant ash to prepare nitrogen-fixing bacteria fertilizer

[0021] The first embodiment of the present invention uses biomass power plant ash to prepare nitrogen-fixing bacteria fertilizer. The process of preparing nitrogen-fixing bacteria fertilizer from biomass power plant ash is described in detail below through method one and method two respectively.

[0022] method one:

[0023] (1) Fermentation nitrogen-fixing strains;

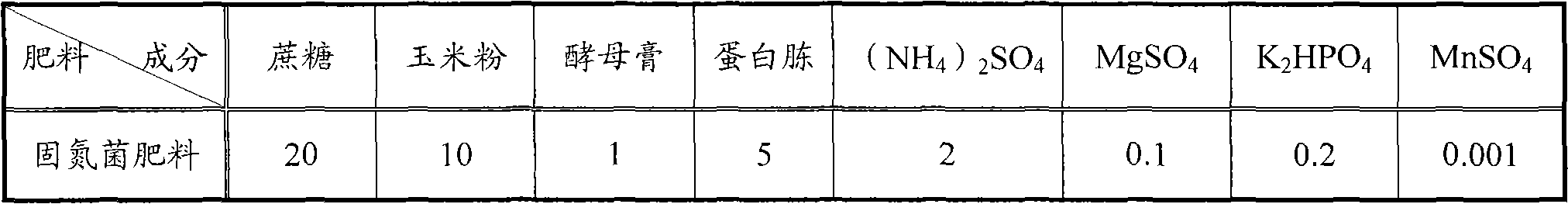

[0024] After activation of nitrogen-fixing bacteria, transfer to sterilized LB or YPGA liquid seed culture medium, adjust pH 7.0-7.5, incubate at 30℃-32℃ for 12-16 hours, and then transfer to killed according to 1%-5% inoculum Bacteria in a large tank of culture medium. In a large tank culture medium, culture at 30℃-32℃ for 14-18 hours, other fermentation conditions are operated according to conventional techniques, and the number of bacteria reaches 5-10×10 9 CFU / ml. See Table 1 for the formulation of the large...

no. 2 example

[0039] Second embodiment: Using biomass power plant ash to prepare compound microbial fertilizer

[0040] The first embodiment of the present invention uses biomass power plant ash to prepare compound microbial fertilizer. The process of preparing composite microbial fertilizer using biomass power plant ash will be described in detail below.

[0041] (1) Fermentation strains;

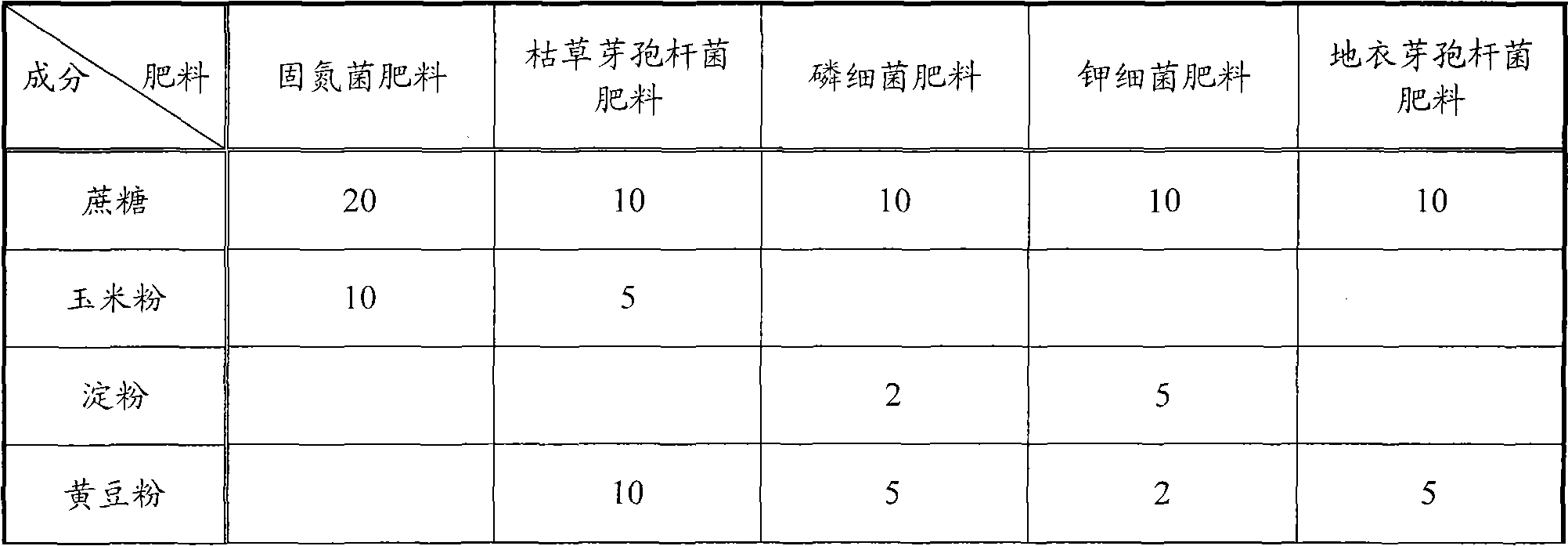

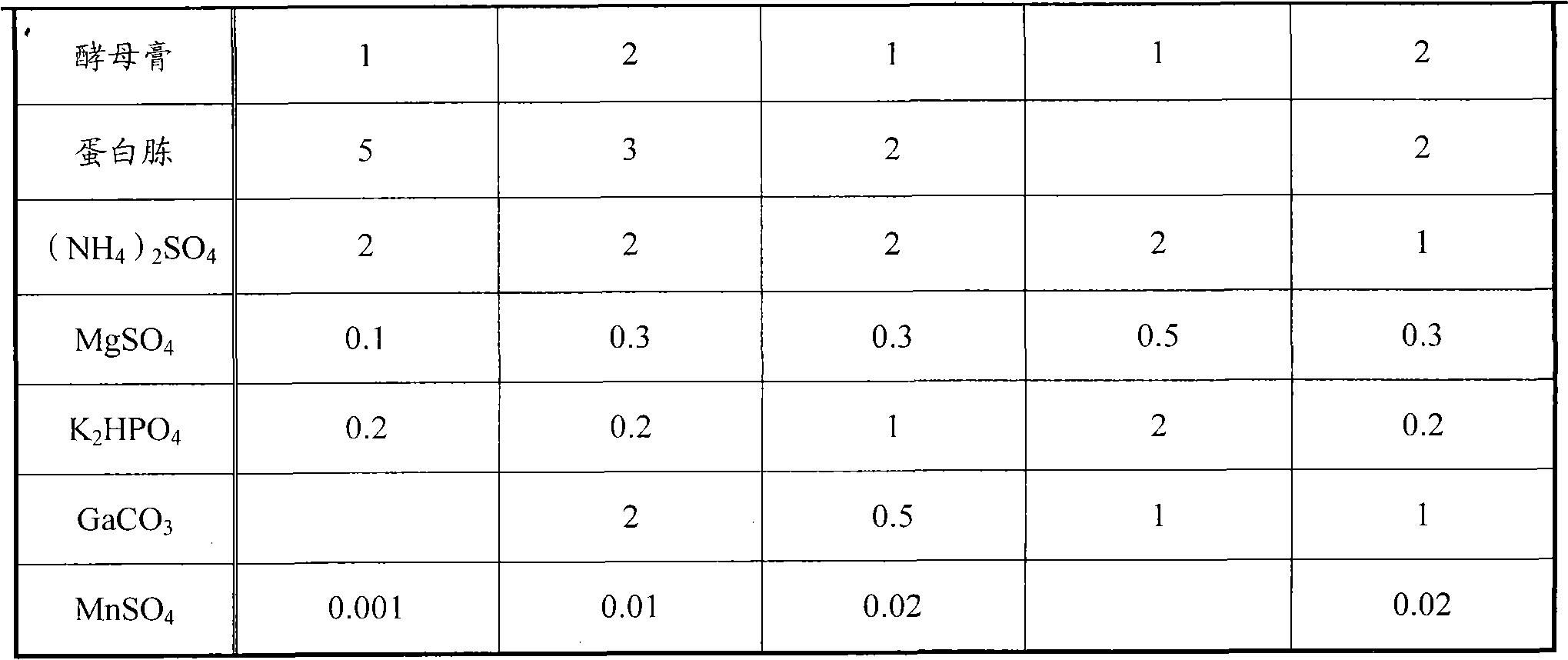

[0042] The Azotobacter, Bacillus subtilis, Phosphobacteria and Bacillus licheniformis that are to be produced are activated separately and transferred to LB or YPGA liquid seed culture medium, and potassium bacteria are activated and transferred to potassium bacteria culture medium. After culturing at 30°C-37°C for 12-16 hours, they are then transferred to a large tank medium at 1%-5% inoculum. The culture temperature and time were 16 hours for nitrogen-fixing bacteria at 30°C, 36 hours for Bacillus subtilis at 30°C, 32 hours for phosphorus bacteria at 32°C, 32 hours for Bacillus licheniformis at 37°C, and 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com