Preparation method for bamboo pulp cellulose-based integrated Fenton catalyst Fe<3+>C2O4/R

An integrated Fenton and cellulose-based technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc., can solve high oxidation cost, low degradation efficiency, Fenton To solve the problems such as the difficulty of recycling the reagents, to expand the range of raw materials and increase economic income

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

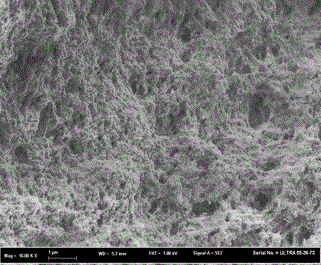

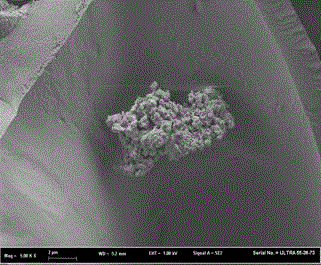

Image

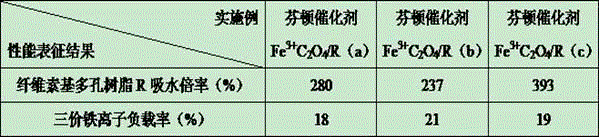

Examples

Embodiment 1

[0017] 1) Pulverize the light bamboo pulp board with a plant grinder, filter it through a 100-mesh sieve to obtain bamboo pulp powder with a particle size of 0.15 mm or less, add the alkaline solution pre-frozen to -10°C and stir vigorously for 4 minutes, and let it stand for 120 minutes min, wherein the alkaline solution is a mixed solution of sodium hydroxide and urea, the mass percentages of sodium hydroxide, urea and deionized water are 6 wt%, 11 wt% and 83 wt%, respectively, bamboo pulp powder and mixed solution are 2 g : 70 mL was mixed and reacted, then taken out and placed in an ice bath for stirring to obtain a uniform transparent bamboo pulp cellulose solution;

[0018] 2) Under the action of mechanical stirring, the bamboo pulp cellulose solution obtained in step 1) was heated to 70°C in a water bath, nitrogen gas was introduced for 20 min, 0.1 g / g ammonium persulfate of bamboo pulp powder was added for 20 min, and 0.5 g / g bamboo pulp powder acrylamide, 2.0 g / g bamb...

Embodiment 2

[0021]1) Pulverize the purple bamboo pulp board with a plant grinder, filter it through a 100-mesh sieve, and obtain bamboo pulp powder with a particle size of 0.15 mm or less, add the alkaline solution pre-frozen to -15°C and stir vigorously for 3 minutes, and let it stand for 90 minutes. min, wherein the alkaline solution is a mixed solution of sodium hydroxide and urea, the mass percentages of sodium hydroxide, urea and deionized water are 5 wt%, 10 wt% and 85 wt%, respectively, bamboo pulp powder and mixed solution are 2 g : 60 mL was mixed and reacted, then taken out and placed in an ice bath for stirring to obtain a uniform transparent bamboo pulp cellulose solution;

[0022] 2) Under the action of mechanical stirring, the bamboo pulp cellulose solution obtained in step 1) was heated to 60°C in a water bath, nitrogen gas was introduced for 30 minutes, 0.15 g / g ammonium persulfate of bamboo pulp powder was added for 15 minutes, and 0.75 g / g bamboo pulp powder acrylamide, ...

Embodiment 3

[0025] 1) Pulverize the purple bamboo pulp board with a plant grinder, filter it through a 100-mesh sieve to obtain bamboo pulp powder with a particle size of 0.15 mm or less, add the alkaline solution pre-frozen to -25°C and stir vigorously for 2 minutes, and let it stand for 60 minutes. min, wherein the alkaline solution is a mixed solution of sodium hydroxide and urea, the mass percentages of sodium hydroxide, urea and deionized water are 4 wt%, 9 wt% and 87 wt%, respectively, bamboo pulp powder and the mixed solution are 2 g : 50 mL was mixed and reacted, then taken out and placed in an ice bath for stirring to obtain a uniform transparent bamboo pulp cellulose solution;

[0026] 2) Under the action of mechanical stirring, the bamboo pulp cellulose solution obtained in step 1) was heated to 50 °C in a water bath, nitrogen gas was passed through for 40 min, and 0.2 g / g ammonium persulfate of bamboo pulp powder was added to trigger for 10 min, followed by adding 1.0 g / g acry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com