3D (three dimensional) printing manufacturing method of seal

A 3D printing and manufacturing method technology, applied in the field of seal processing, can solve the problems of high cost, cumbersome production of metal seals, and single structure of the seal, so as to reduce production costs, make up for the defects of machining and casting processes, and overcome The effect of a single structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

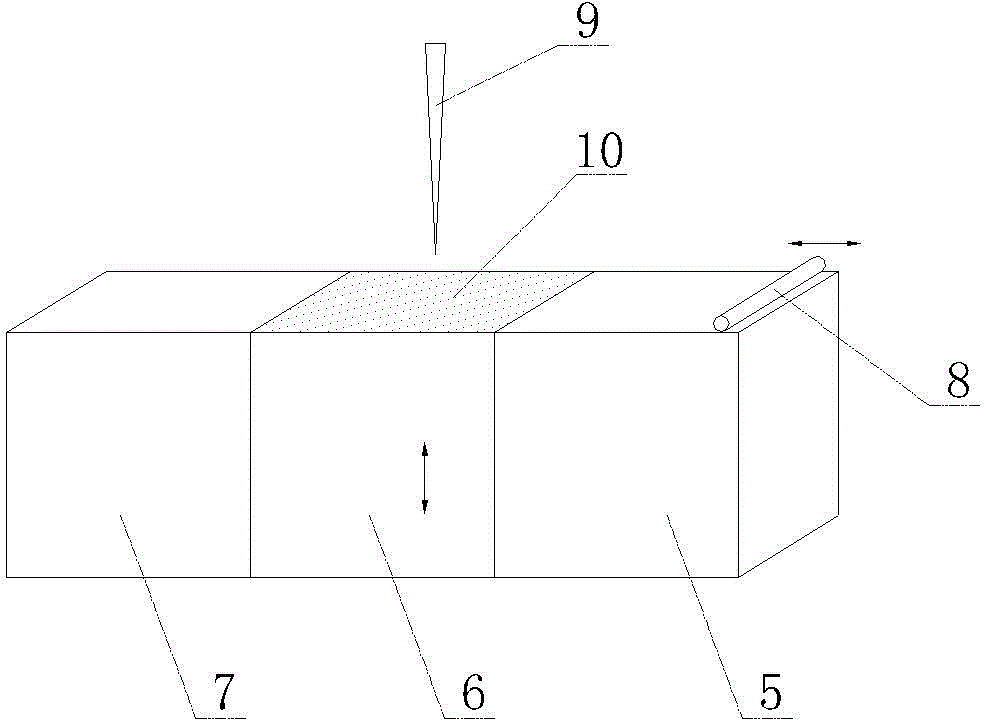

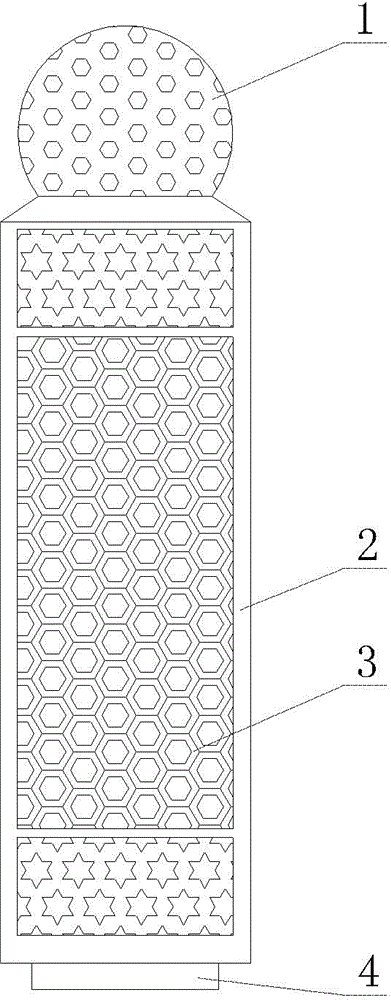

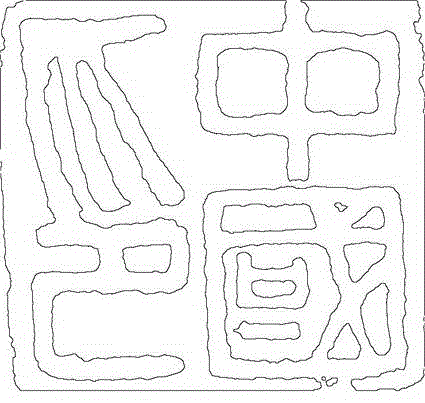

[0024] A 3D printing manufacturing method for stamps. The additive manufacturing equipment adopts EOSINT M280, and the supporting software is PSW3.5. (1) According to the customer's requirements, use three-dimensional drawing software such as solidworks, UG, ProE or CATIA to design for it The overall three-dimensional model of the seal, including the seal surface, seal button, and border. The main body of the seal can be a solid structure or a hollow structure. The design of the seal surface and border can be computer-generated text or patterns, or it can be based on calligraphy and painting. Works, handwriting, photographs, etc. generate relief or hollowed-out facades; for the structure of the seal in this embodiment, see figure 2 and image 3 , 1 is the stamp, 2 is the main body of the seal, 3 is the side, and 4 is the surface of the seal. (2) Use the software RP-Tools to process the 3D model of the seal in two dimensions: cut the structure into layers in the direction of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com