3D printing manufacturing method of PDC drill body

A manufacturing method and 3D printing technology, applied in the directions of additive manufacturing, process efficiency improvement, energy efficiency improvement, etc., can solve the problems of cumbersome production, high cost, long cycle, etc., to improve the overall performance, reduce the production cost, make up for the machine Effects of defects in machining and casting processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

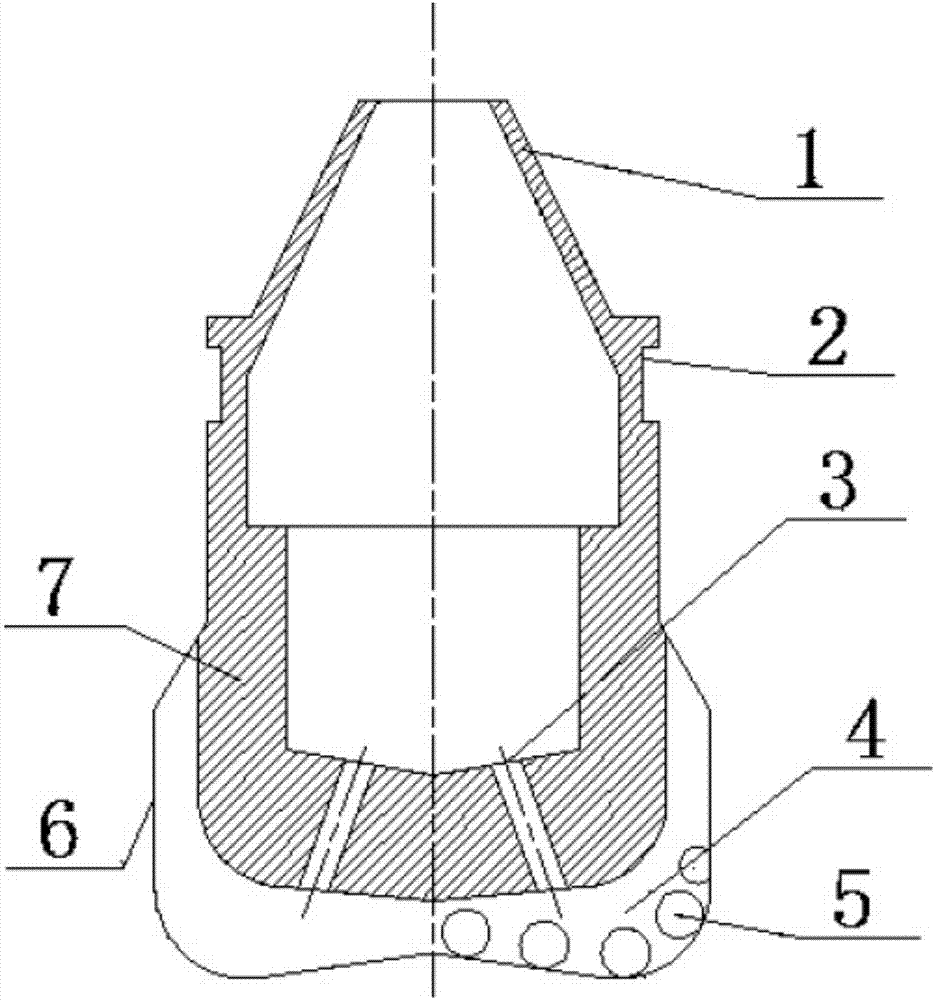

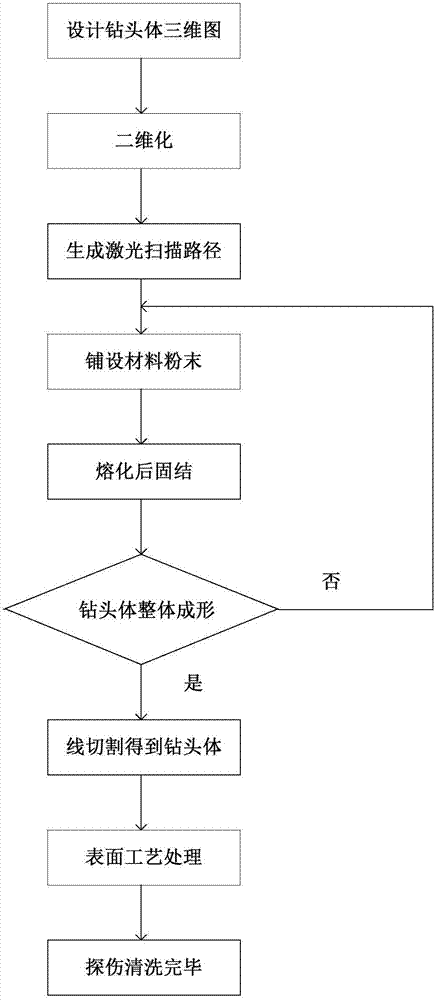

[0021] The schematic diagram of the PDC drill body structure in the present embodiment, as figure 1 As shown, the specific operation steps are as follows figure 2 shown. According to the specific requirements of the design, use 3D drawing software such as AutoCAD, Unigraphics NX, Pro-E or CATIA to design the overall 3D model of the PDC bit body, including the screw thread 1 of the PDC bit body, the shackle groove 2, the nozzle hole 3, and the scraper Wing 4, PDC cutter 5, gauge and crown 6, bit body 7, etc., use the software RP-Tools to process the 3D model of the PDC bit body in two dimensions:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com