Full light path aberration correction system and full light path aberration correction method based on double Hartmann sensors

An aberration correction, sensor technology, used in optics, instruments, optical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

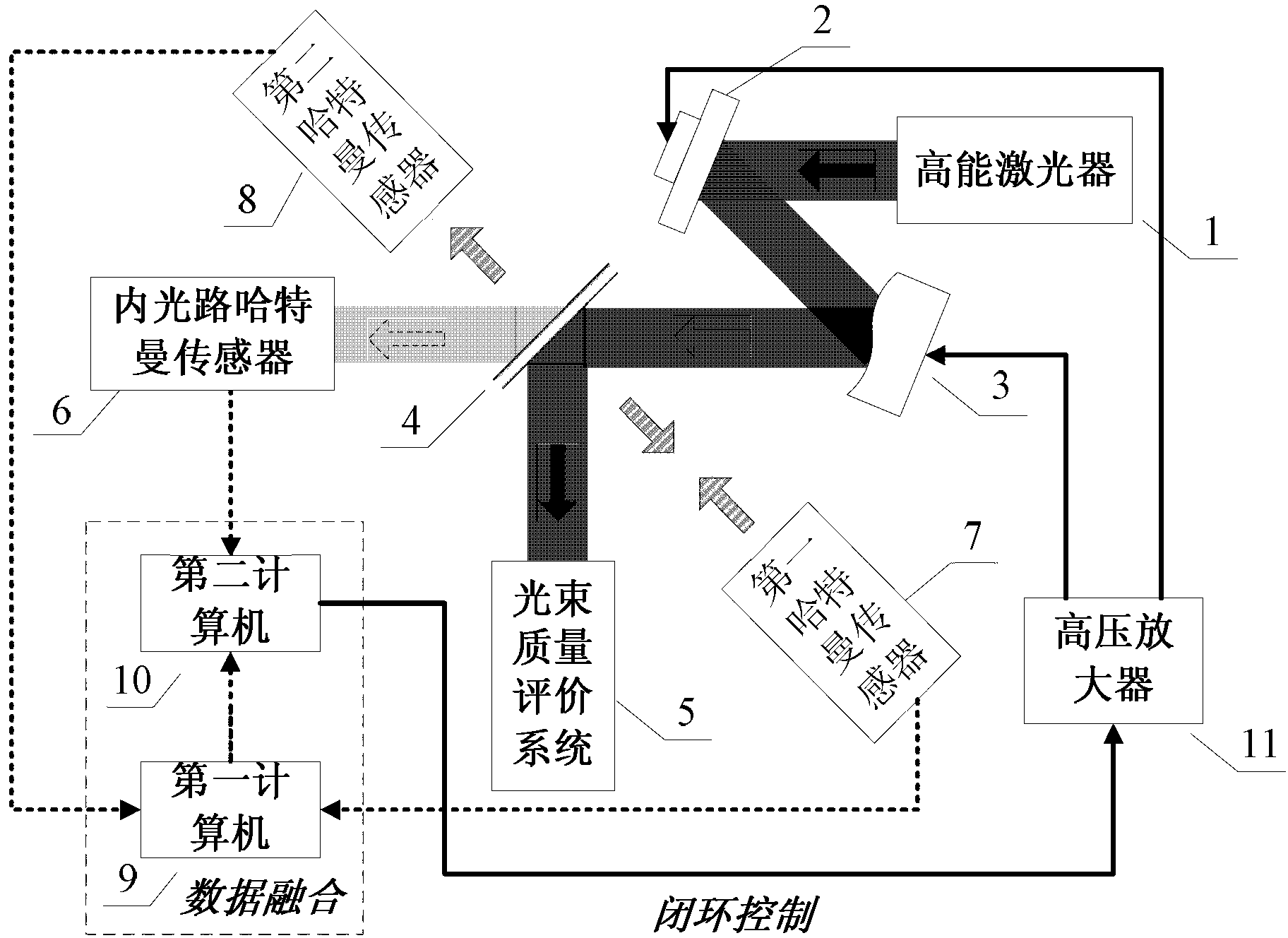

[0077] Such as figure 1 As shown, the present invention is an all-optical aberration correction system based on double Hartmann sensors, which includes a high-energy laser 1, a wavefront corrector, a beam splitter 4, a beam quality evaluation system 5, and an inner optical path Hartmann sensor 6 , the first Hartmann sensor 7, the second Hartmann sensor 8, data fusion assembly and high-voltage amplifier 11; the wavefront corrector includes a tilting mirror 2 and a deformable mirror 3, and the data fusion assembly includes a first computer 9 and a second computer 10. The high-power laser light emitted by the high-energy laser 1 successively enters the tilting mirror 2 and the deforming mirror 3 at a small angle, and then enters the front surface of the beam splitter 4 at a certain angle; wherein, a part of the energy (mostly) is split ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com