Counterweight-frame heat-shrinkable film packaging machine

A counterweight frame and packaging machine technology, applied in the field of elevators, can solve the problems of uneven and clean product appearance, high labor intensity of workers, and large resource consumption, so as to improve packaging production efficiency, reduce labor intensity, and reduce resource consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

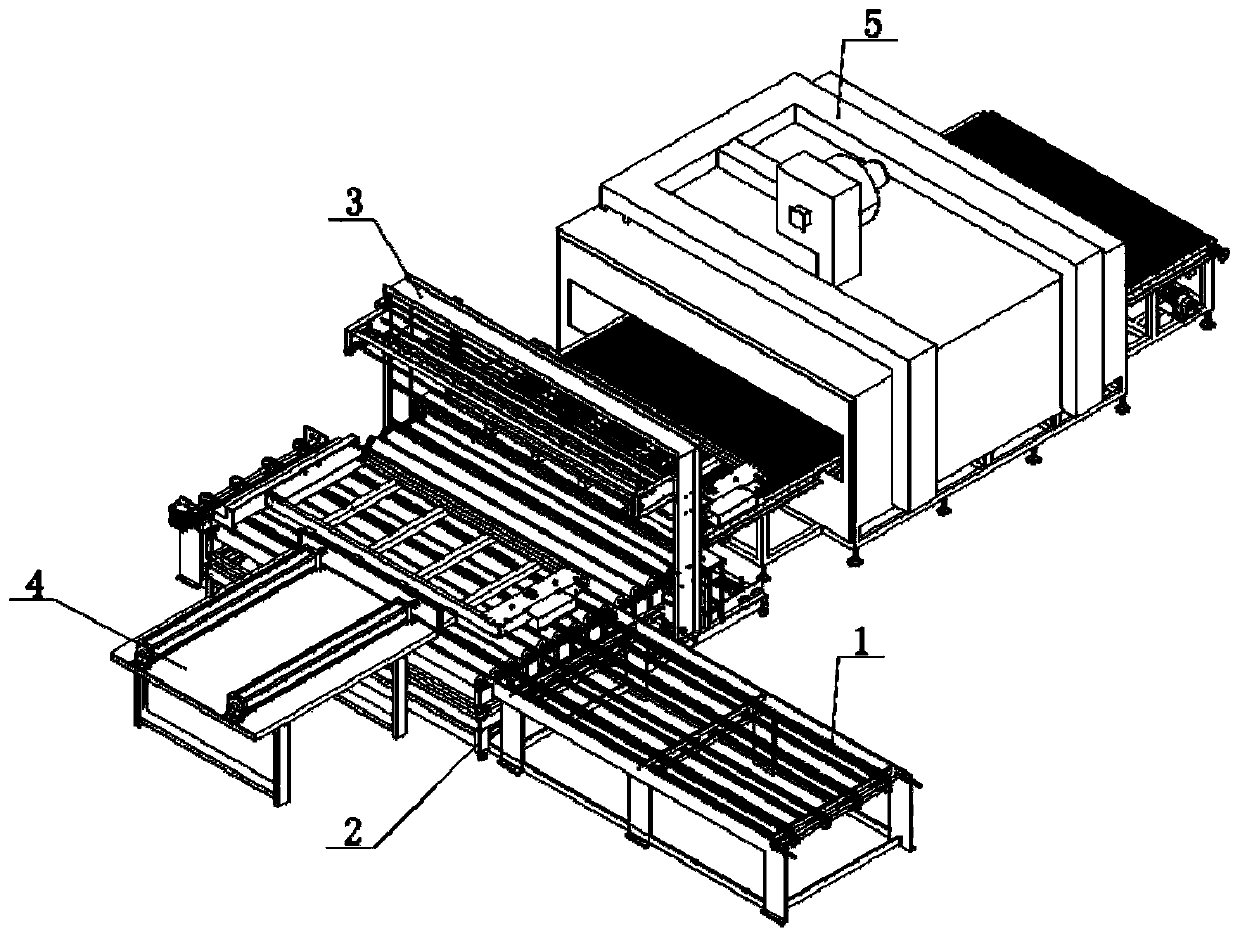

[0024] Embodiment: As shown in the accompanying drawings, this type of counterweight frame shrink film packaging machine mainly includes a longitudinal chain conveyor 1, a horizontal unpowered roller conveyor 2, a film supply wrapping mechanism 3, a pushing device 4, a heat dryer and Electrical control part 5, counterweight frame 6, vertical chain conveyor 1 is arranged behind pushing device 4, horizontal unpowered roller conveyor 2 is installed in the cavity inside longitudinal chain conveyor 1, and horizontal unpowered roller conveyor 2 rear is provided with supply The film wrapping mechanism 3 is connected to the heat dryer and the electrical control part 5 behind the film wrapping mechanism 3 .

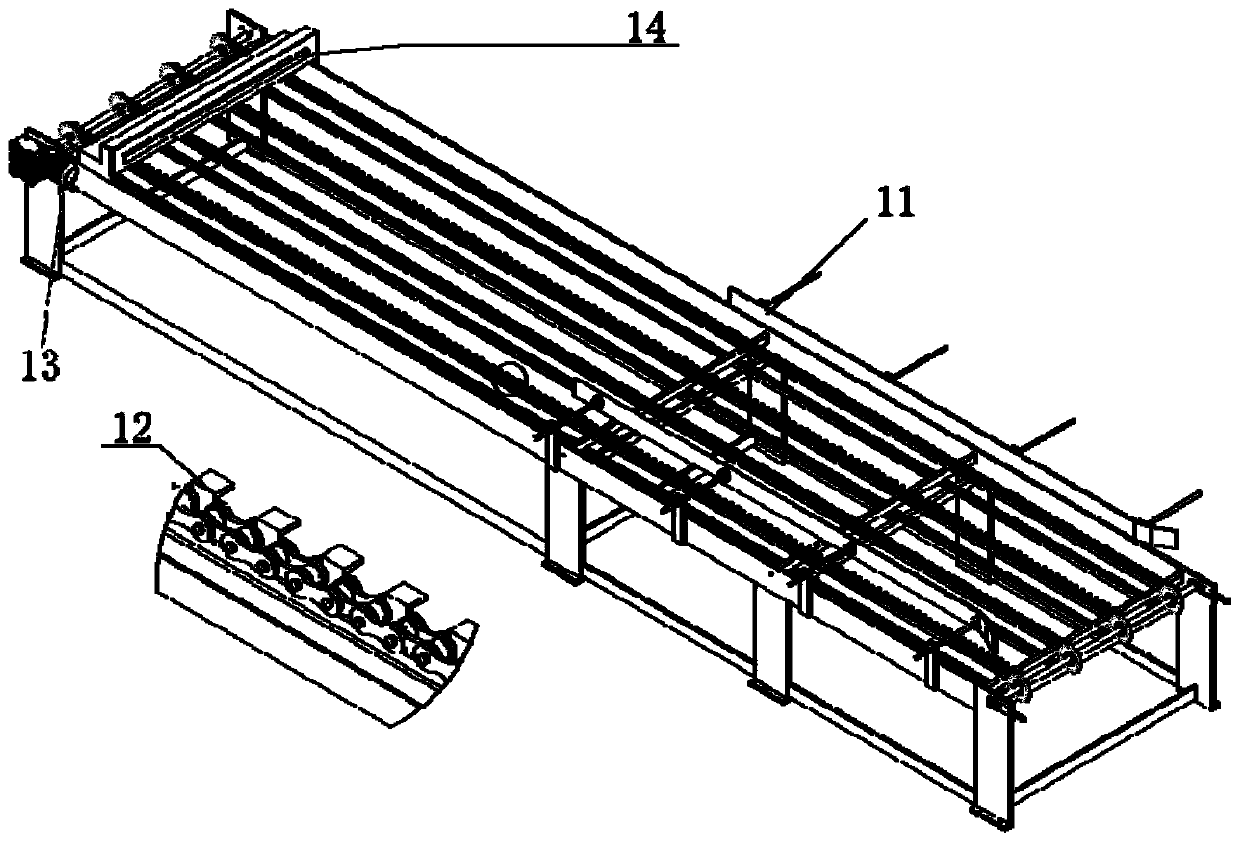

[0025] The right side of described longitudinal chain conveyor 1 is provided with two guardrails 11 in parallel, is used for position-limiting counterweight frame 6, and longitudinal chain conveyor 1 is provided with four curved plate conveying chains 12 connected and driven by mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com