High-performance compound substrate membrane containing positioning lasing and printing pattern and making method of compound substrate membrane

A technology for printing patterns and production methods, which is applied in the directions of chemical instruments and methods, temperature recording methods, lamination auxiliary operations, etc., can solve the problems of poor followability of composite base film, poor surface reprintability, discoloration, etc. Good reprintability, high anti-counterfeiting value, and high anti-counterfeiting function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

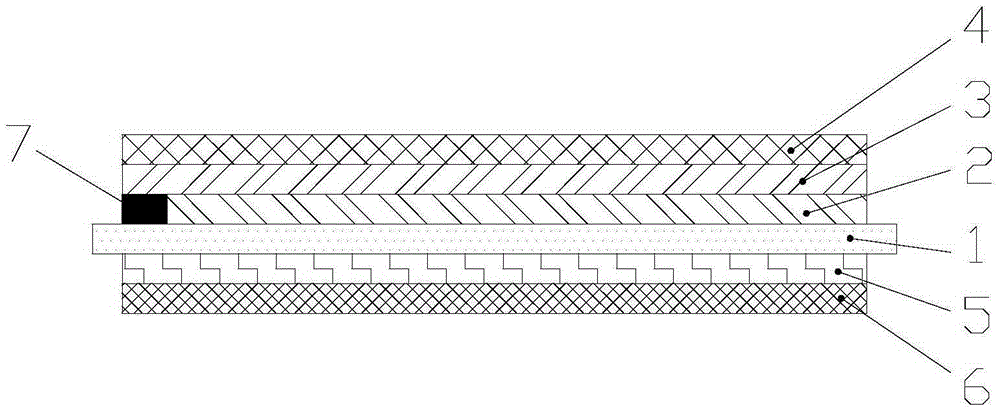

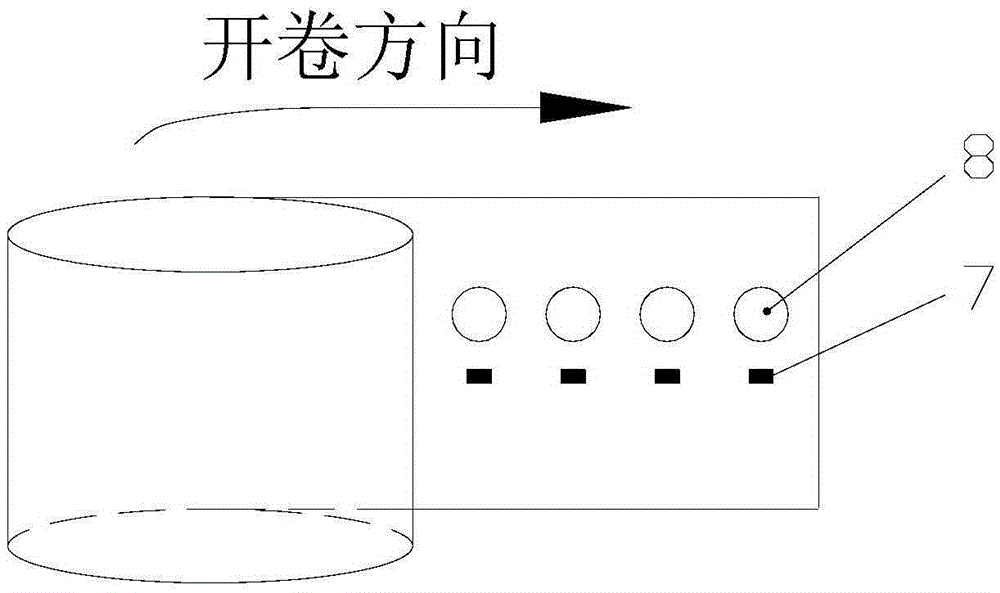

[0028] As shown in the accompanying drawings, the present invention provides a high-performance composite base film containing positioning lasers and printed patterns, including a positioning printing layer 4, a medium layer 3, an information layer 2, and a positioning substrate 1 sequentially compounded from top to bottom. , composite glue 5 and base film 6. That is to say, the information layer 2 is uniformly coated on the surface of the positioning substrate 1, and the information layer 2 is processed with a laser plate to produce a laser information pattern containing a positioning mark, and aluminum or a dielectric layer 3 is plated on the laser information pattern to make the pattern It is more shining, and finally the positioning printing layer 4 is made on the surface, and the other side of the positioning substrate 1 is formed by compounding the composite glue 5 and the base film 6 . Among them, the positioning substrate 1 adopts biaxially stretched polyester film BOP...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com