PE (polyethylene) film packaging machine for cloth roll

A cloth roll and film wrapping technology, applied in packaging and other directions, can solve the problems of affecting the aesthetics of the packaging, the packaging PE film is not compact and flat, etc., and achieve the effect of improving the flatness and the overall beauty of the packaging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

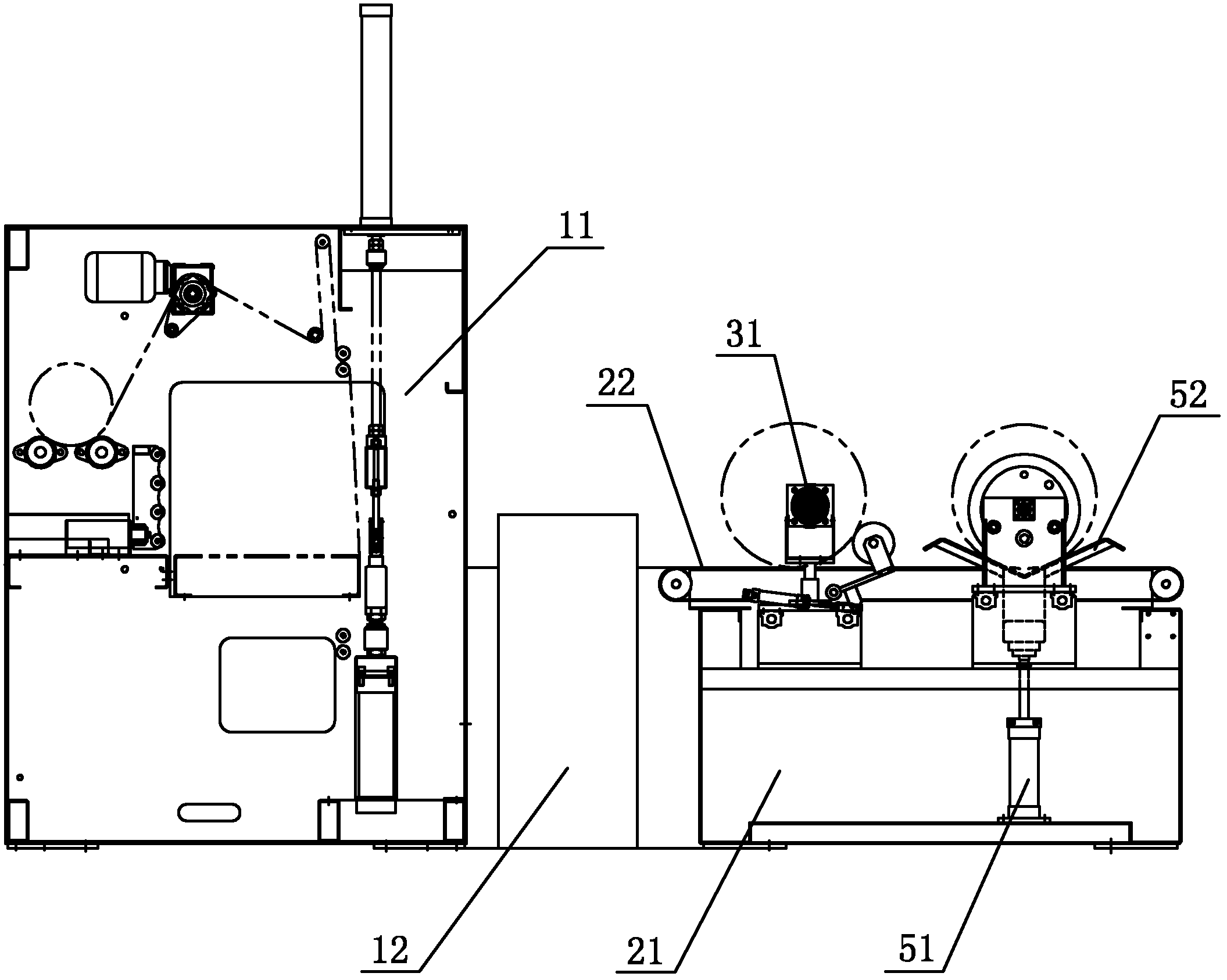

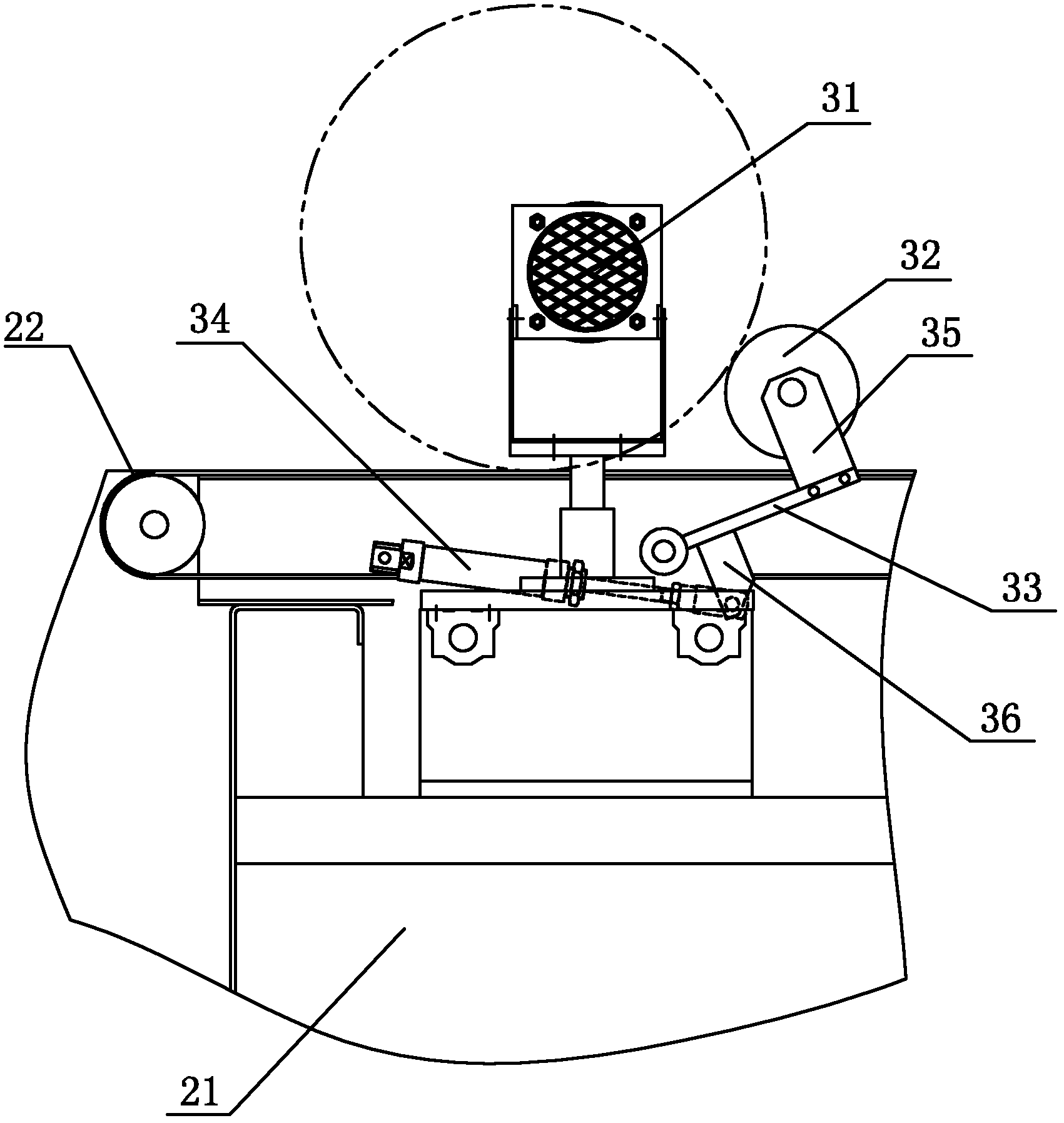

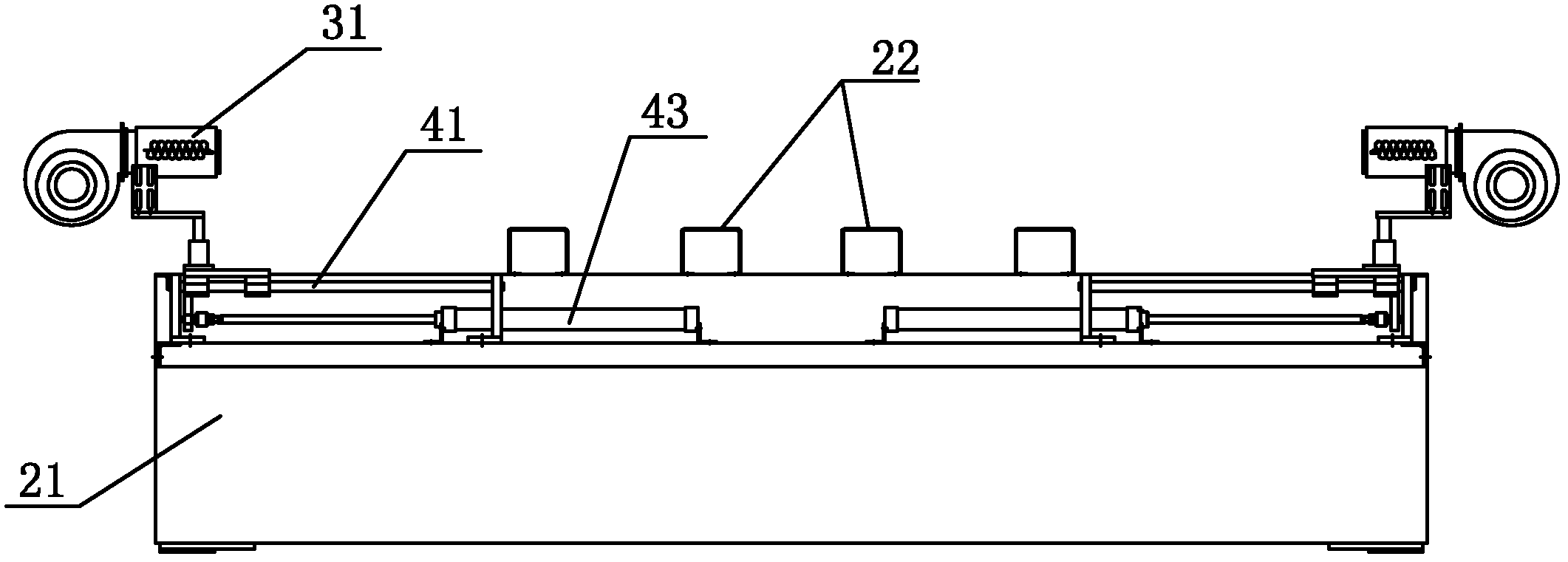

[0022] As shown in the figure, a PE film packaging machine for cloth rolls includes a cloth feeding mechanism (not shown in the figure), a PE film automatic packaging mechanism 11, an end cutting mechanism 12, a frame 21, and a conveyor belt 22. The rear side of the cutting mechanism 12 is provided with a hot blowing device and an end flattening device in turn, and the hot blowing device is a hot blower 31 arranged on both sides of the frame 21, and the frame 21 is provided with a device for making the cloth roll in situ. The supporting wheel device of rotation, the supporting wheel device is positioned at the rear side of hot blower 31, and supporting wheel device comprises supporting wheel 32, connecting rod 33 and the first driving cylinder 34, and one end of connecting rod 33 is pivotally connected on the frame 21, and connecting rod The o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com