Wire winding device

A winding equipment and winding technology, applied in the directions of transportation and packaging, packaging, single objects, etc., can solve the problems of low winding efficiency, poor consistency, and poor product packaging aesthetics, and achieve high winding efficiency and reduce labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

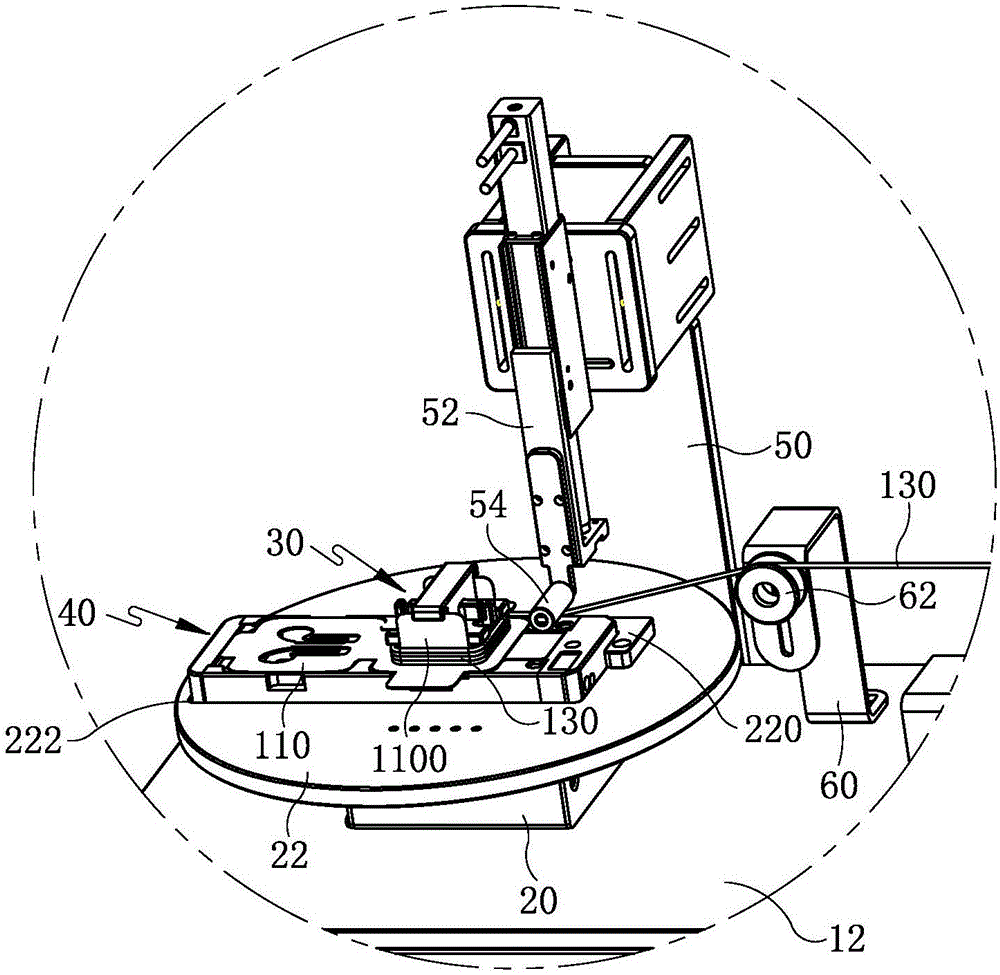

[0031] Below in conjunction with accompanying drawing and embodiment, further elaborate the present invention.

[0032] The orientations involved in this manual are all based on the orientation of the winding equipment of the present invention when it is in normal operation, and are not limited to its orientation during storage and transportation, and only represent relative positional relationships, not absolute positional relationships.

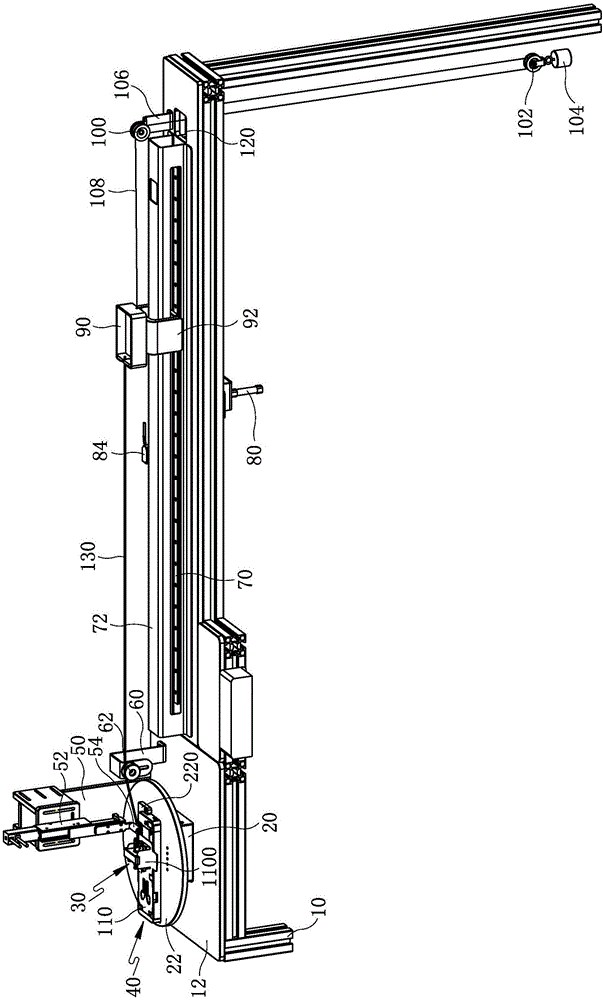

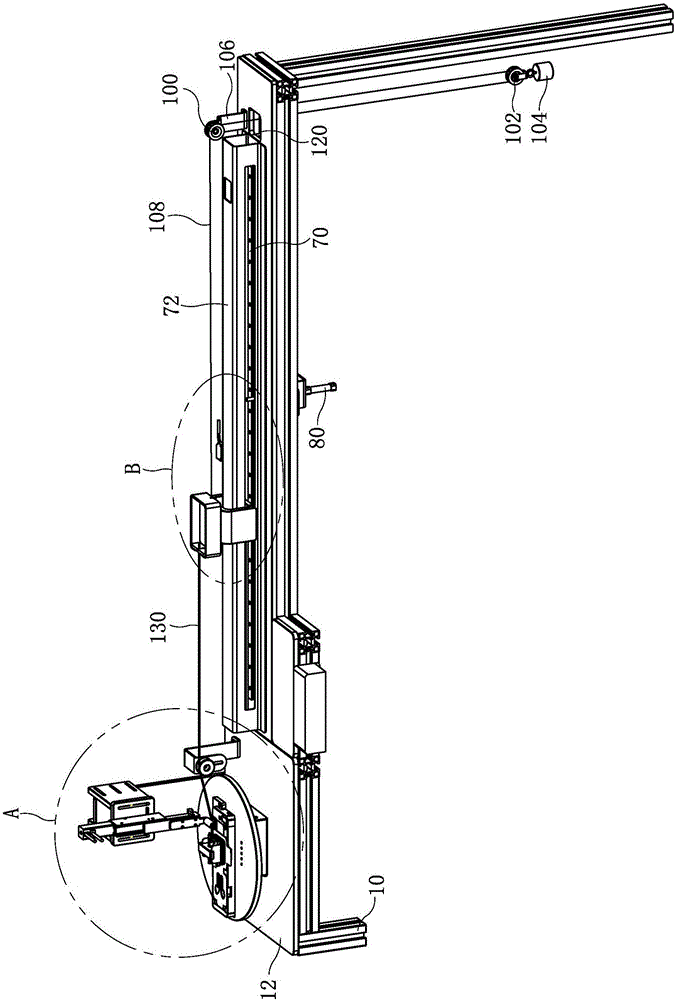

[0033] Such as figure 1 As shown, a wire winding device is used to automatically wind wires when packaging electronic products with wires such as earphones, mice, and chargers, which can improve the consistency and aesthetics of electronic product packaging. Including a frame 10, the upper end of the frame 10 is provided with a workbench 12, and the workbench 12 is composed of two parts connected horizontally, including a rectangular or square workbench with a larger width on one side, and a workbench on the other side. A long workbench wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com