Carton packaging machine

A baler and carton technology, which is applied in the packaging, transportation and packaging of paper products, and the type of packaged items, etc., can solve the problems of affecting transportation and storage, weak packaging, and reduced production efficiency, and achieves convenient transportation and storage. The effect of labor intensity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with examples, but the present invention is not limited to these examples.

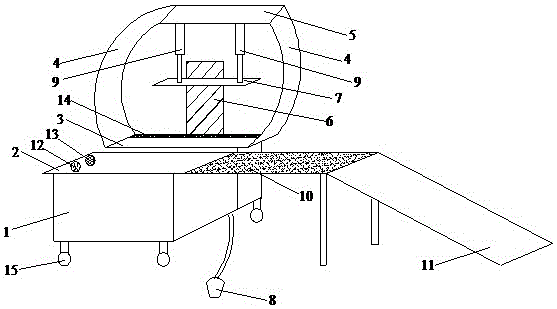

[0016] A carton packing machine, comprising a body 1, on which a first operating platform 2 and a second operating platform 3 are fixedly installed, with a certain distance between them; Cover 4, the top of the protective cover 4 is connected by a horizontal baffle plate 5, a driving device 6 is installed at the rear end of the second operating platform 3, and a pressing plate 7 that can move up and down is installed on the top of the second operating platform 3; The foot switch 8 connected with the driving device 6 is controlled; the pressing plate 7 is driven by a pair of cylinders 9 installed at the bottom of the horizontal baffle 5; The connected slideway 11; the surface of the first operating platform 2 is provided with a cylinder control button 12 and a conveyor belt control button 13, and the surface of the second opera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com