A strip material automatic strapping machine

A fully automatic, strapping machine technology, applied to the parts of strapping machinery, strapping materials, strapping objects, etc., can solve the problems of high labor cost, high labor intensity, complex structure, etc., and achieve simple structure, low failure rate, and high efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

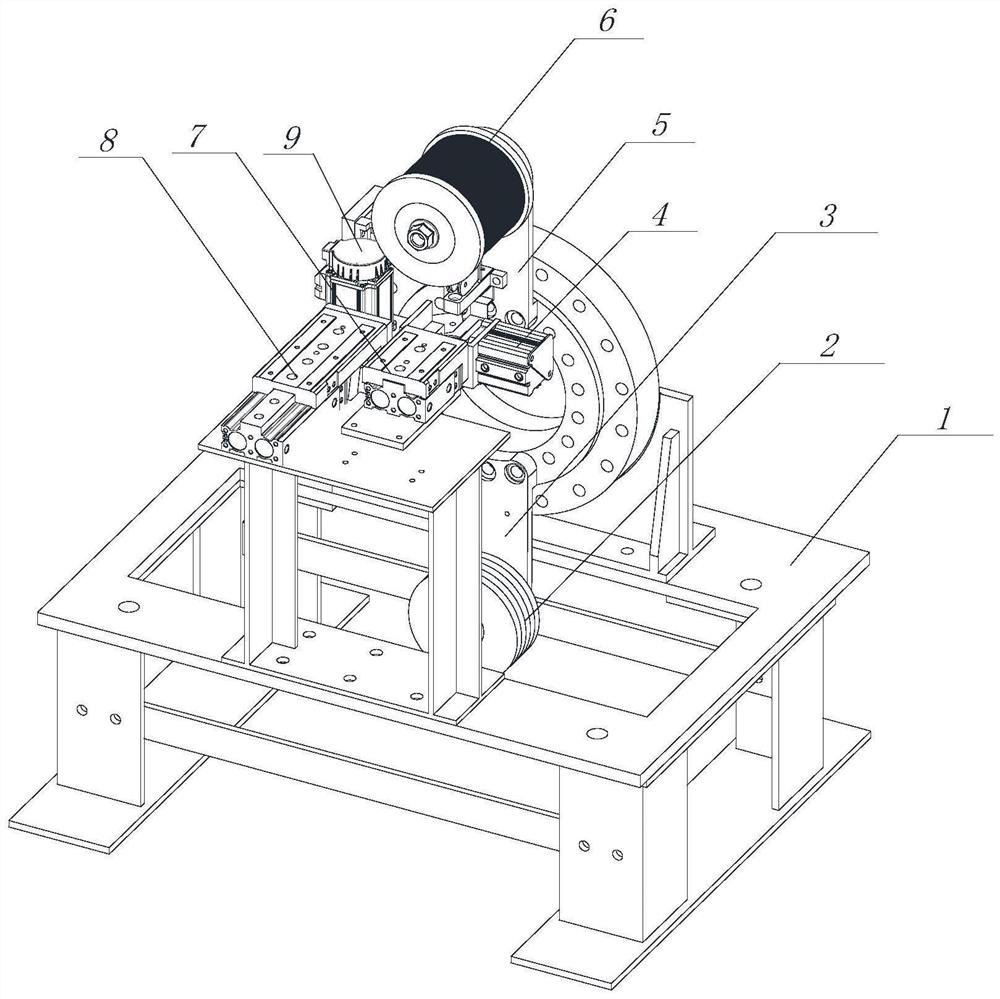

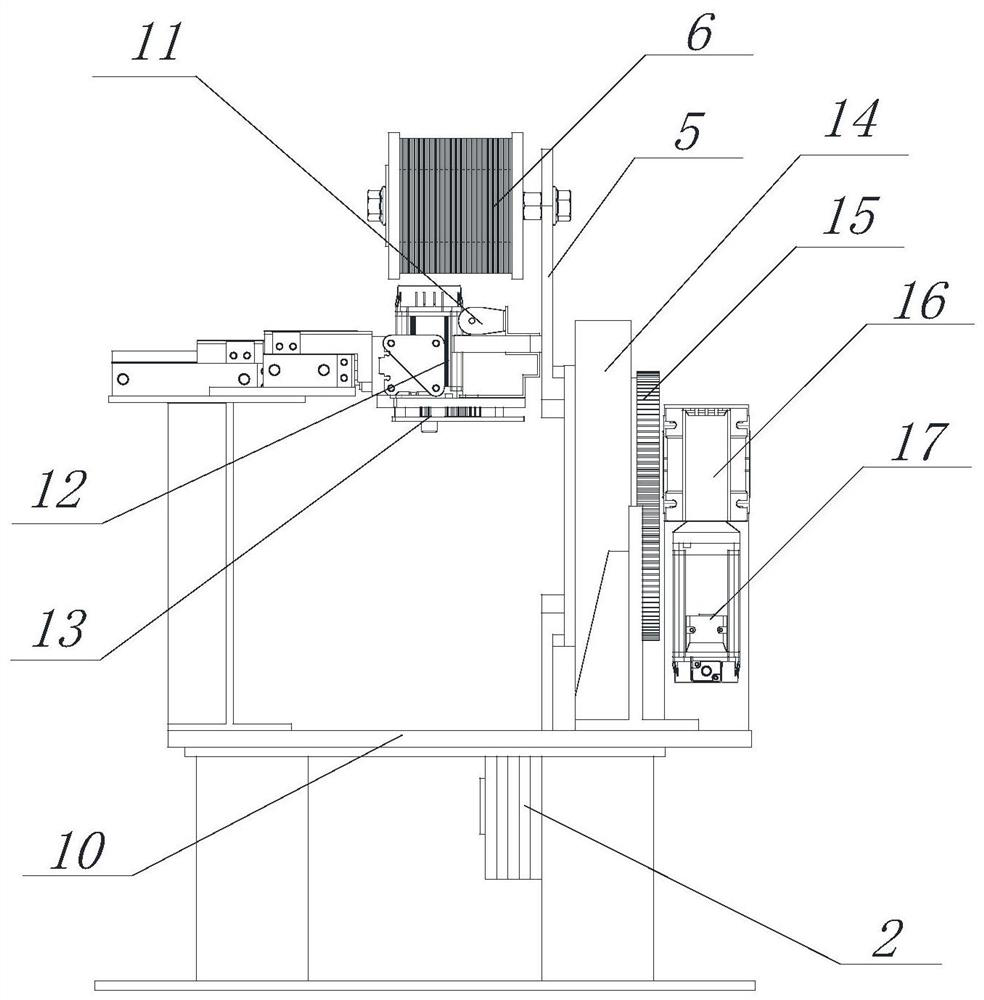

[0024] A preferred embodiment of the present invention will be described below in conjunction with the accompanying drawings, and the technical solution in a preferred embodiment of the present invention will be clearly and completely described.

[0025] See Figure 1-Figure 2 , the present invention includes a frame 1, which is characterized in that: the frame 1 is provided with a wire winding mechanism, a clipping mechanism driving a sliding table 7 and a screwing mechanism driving a sliding table 8; the clipping mechanism driving a sliding table 7 A clamping and shearing mechanism 12 for clamping and cutting the iron wire is installed on it; a wire twisting mechanism 13 for tightening the end of the iron wire after winding is installed on the driving slide table 8 of the wire twisting mechanism.

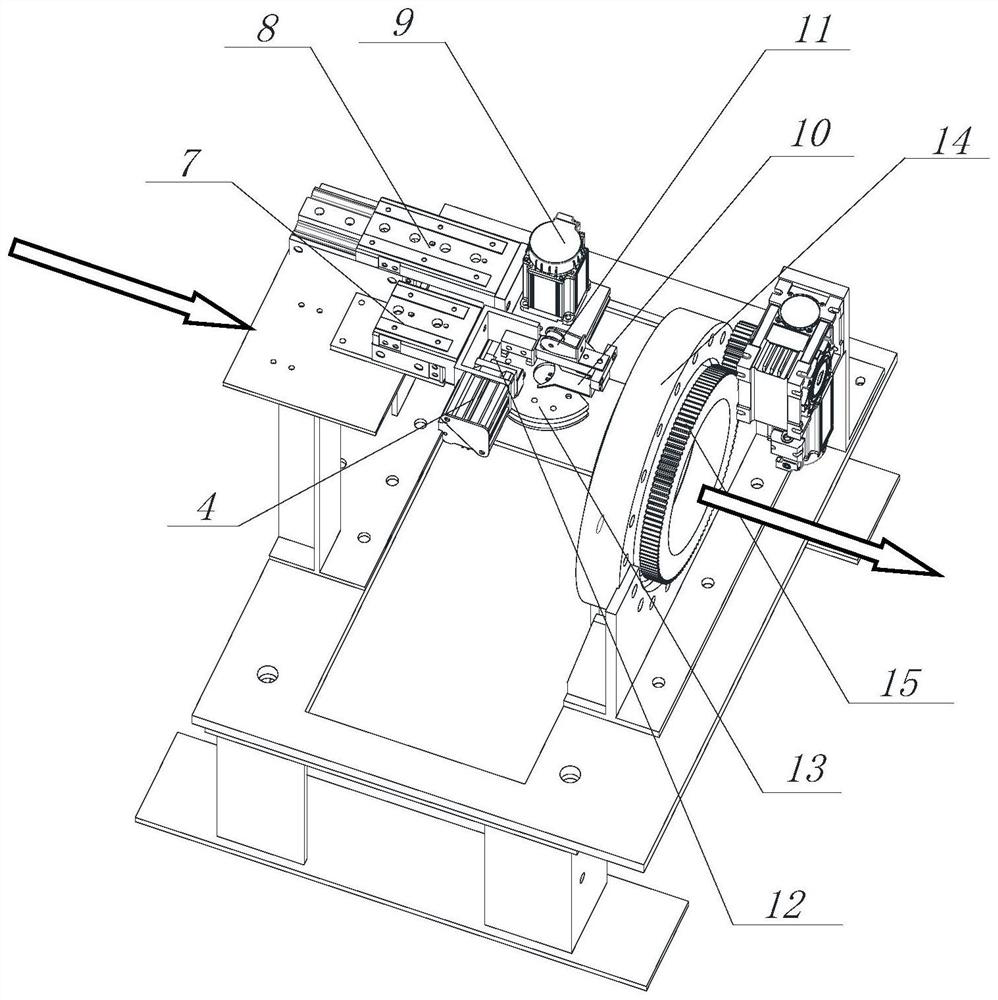

[0026] Such as image 3 As shown, the direction of the arrow is the feeding direction and the discharging direction of the strip material. When bundling, the strip material is fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com