Full-automatic hamburger packaging machine

A hamburger, fully automatic technology, applied in packaging, transport packaging, food packaging, etc., can solve the problems of time-consuming, laborious, manual operation, low work efficiency, etc., to achieve the effect of improving efficiency, beautiful packaging, and realizing the whole process automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

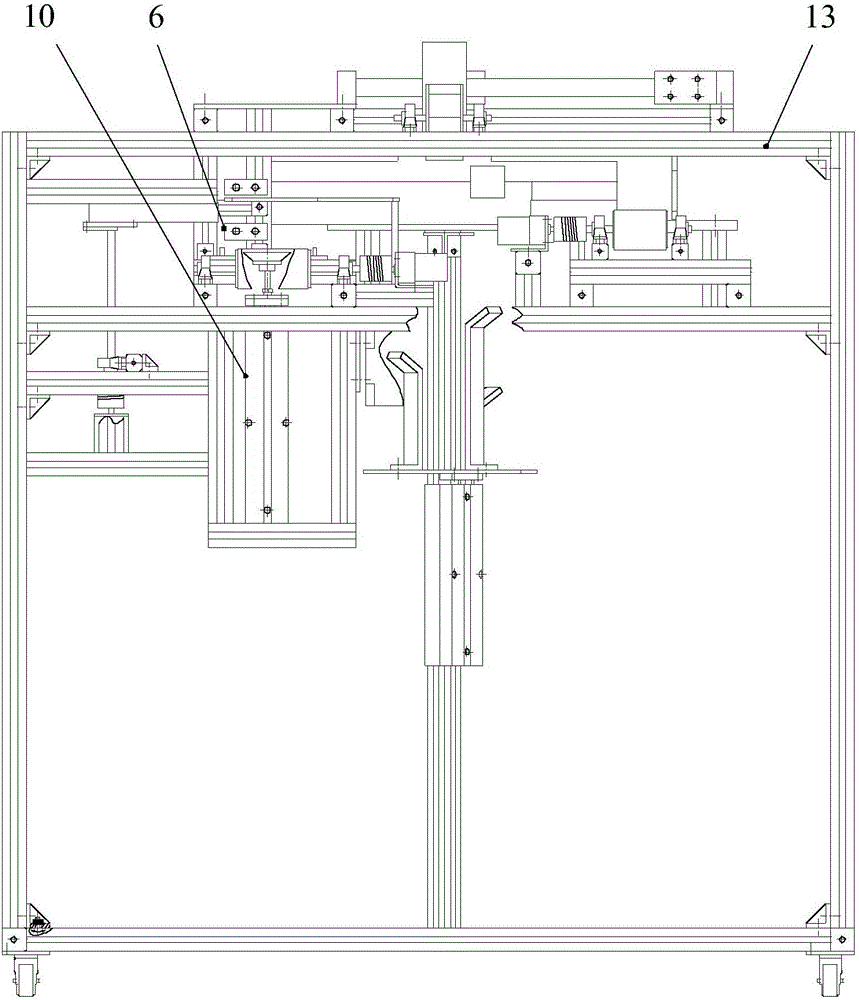

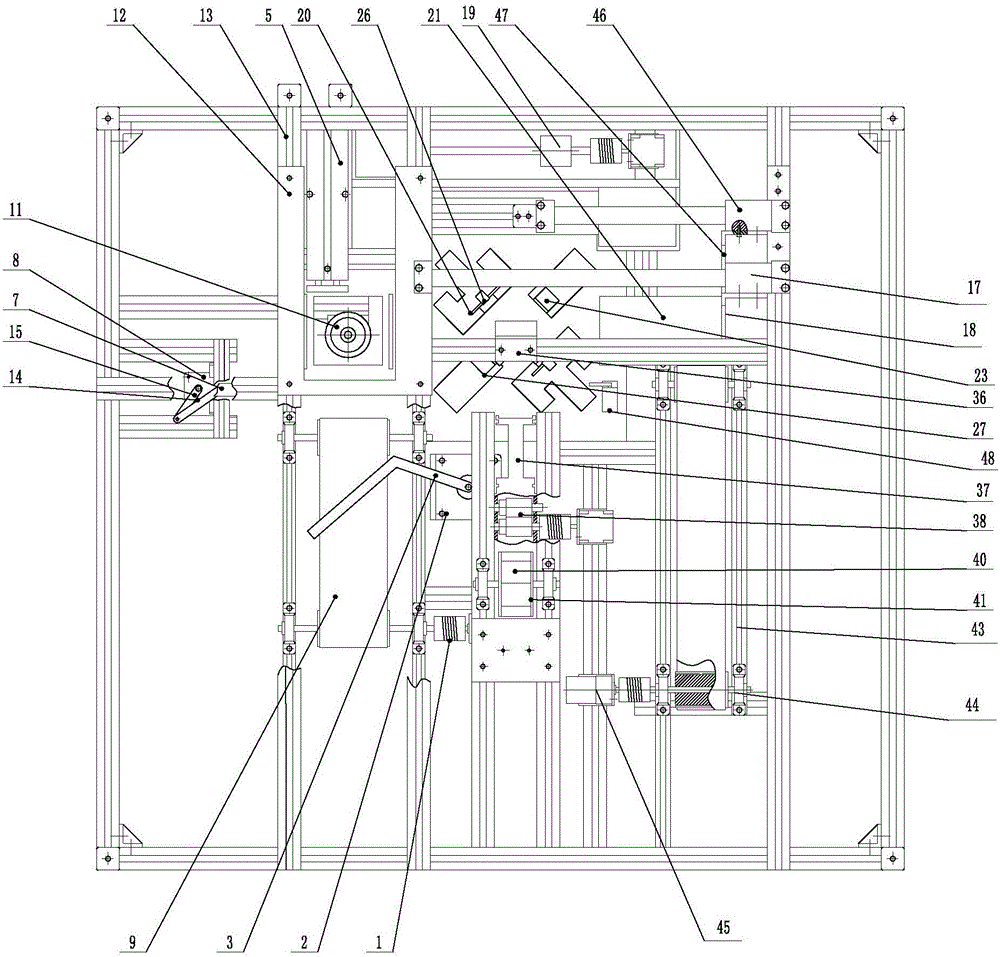

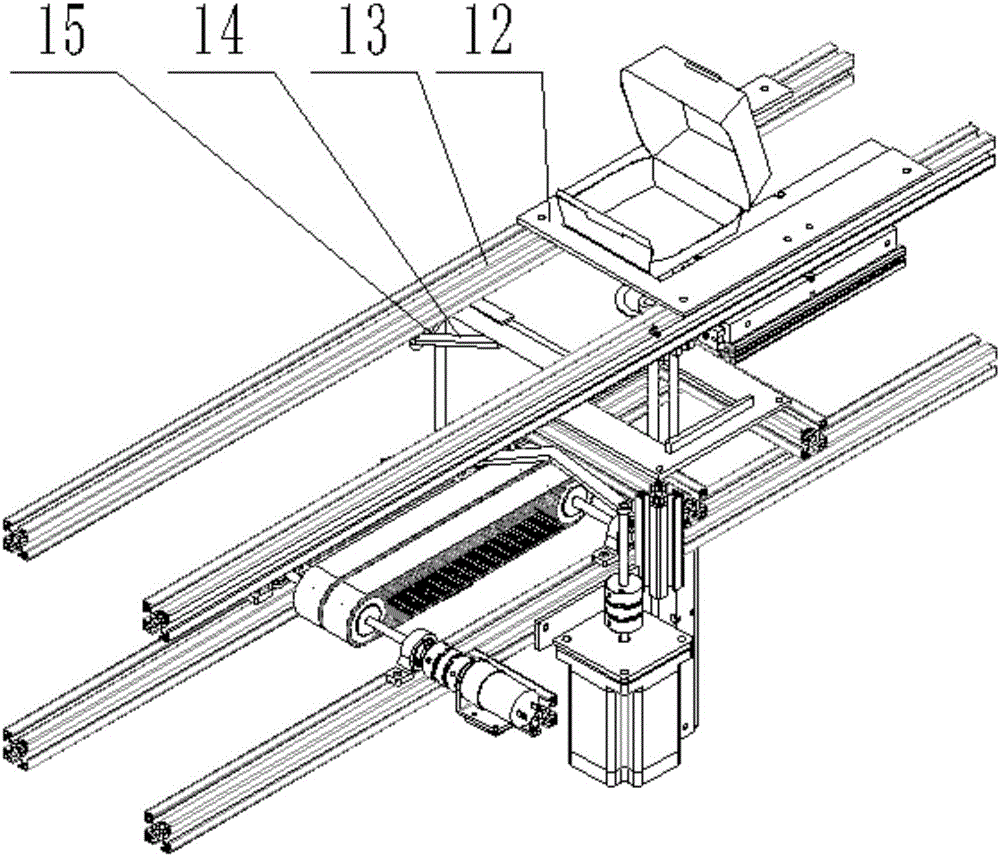

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

[0031] refer to Figure 1 to Figure 12 , a fully automatic hamburger packaging machine, comprising a frame 13 and a hamburger boxing module, the hamburger boxing device includes a box taking mechanism, a hamburger pushing mechanism, a cover box discharging mechanism and a placement platform 12 for placing a hamburger box, the The box-taking mechanism includes a box-taking cylinder 10 and a box-taking suction cup 11, and the upper end of the telescopic rod of the box-taking cylinder 10 is installed with the box-taking suction cup 11, and the box-taking suction cup 11 is located below the placement platform 12; Pushing cylinder 18 and boxing push plate 17 for pushing the wrapped burger 16 to slide along the channel are installed on the frame. The box push plate 17 is located on the passage, and the outlet of the passage is located on the box loading station, and the box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com