Automatic folding machine for extracted paper

A folding machine and automatic technology, applied in the direction of folding thin materials, thin material handling, transportation and packaging, etc., can solve the problems of low production efficiency, product quality decline, paper towel waste packaging, etc., to achieve high production efficiency, clean products, and reduce The effect of labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

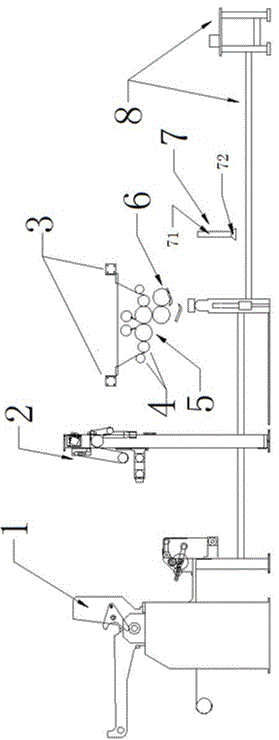

[0022] Such as figure 1 As shown, a paper-drawing automatic folding machine includes a base paper supply device 1 for pre-storing roll paper and providing roll paper, a base paper trimming device 2 for trimming roll paper, and a base paper trimming device 2 for pressing the trimmed roll paper. The crimping wheel 3 for generating crimping lines on paper, the roll paper traction device 4 for pulling the paper body with crimping lines that the crimping wheel 3 arrives, and the cutter for cutting the paper body pulled by the traction device 4 A paper device 5, a folding device 6 for folding the partially overlapped rolled paper cut by the paper cutting device 5, and a pre-pressing device 7 for pre-pressing the rolled paper folded by the folding device 6. The base paper feeding device 1 is connected to the base paper trimming device 2, and the paper outlet of the base paper trimming device 2 is connected to the crimping wheel 3, and the creasing wheel 3 is installed above the tract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com