Composite lithium ion battery diaphragm and preparation method thereof

A lithium-ion battery and composite technology, applied in the direction of secondary batteries, battery components, separators/films/diaphragms/spacers, etc., can solve the problems of low strength and production efficiency, easy short circuit, and easy wiping of the fiber layer In order to reduce the short-circuit rate of the battery, meet the high capacity and improve the performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1) Preparation of electrospinning solution: dissolve polyimide in DMAc (N,N-dimethylacetamide), the polyimide mass volume ratio concentration concentration is 5wt%, measure the polyimide solution The viscosity is 100mPa.S.

[0035] 2) Electrospinning: The prepared polyimide solution electrospinning solution is passed through a nanofiber spinning machine to carry out single-sided continuous electrospinning on a PET non-woven fabric substrate to obtain a PI / PET nanofiber composite film. The electrospinning conditions are as follows: temperature 10°C, positive voltage 20kV, negative voltage 530kV, spinning speed 1g per minute per meter width;

[0036] The composite membrane obtained after the spinning is completed is subjected to post-treatment: first, it is formed by hot pressing with a roller at 80° C., and then dried in an oven at 120° C. for 1 minute.

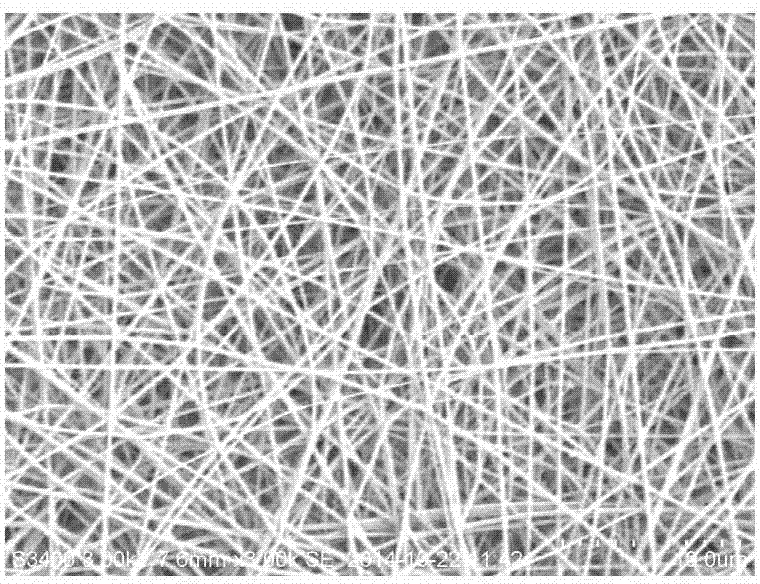

[0037] Electron micrographs of the surface of unmodified non-woven fabric samples are as follows: figure 1 As shown...

Embodiment 2

[0042] 1) Preparation of electrospinning solution: Preparation of electrospinning solution: dissolve polyimide in DMAc (N,N-dimethylacetamide), the mass volume ratio concentration of polyimide is 30wt%, and measure the The viscosity of the polyimide solution is 3000mPa.S.

[0043] 2) Electrospinning: The prepared polyimide solution electrospinning solution is carried out double-sided continuous electrospinning on the PET non-woven fabric substrate through a nanofiber spinning machine to obtain a PI / PET nanofiber composite film, The electrospinning conditions are: temperature 40°C, positive voltage 50kV, negative voltage 30kV, spinning speed 10g per minute per meter width;

[0044] The composite membrane obtained after the spinning is completed is subjected to post-treatment: first, it is formed by hot pressing with a roller at 200° C., and then dried in an oven at 120° C. for 5 minutes.

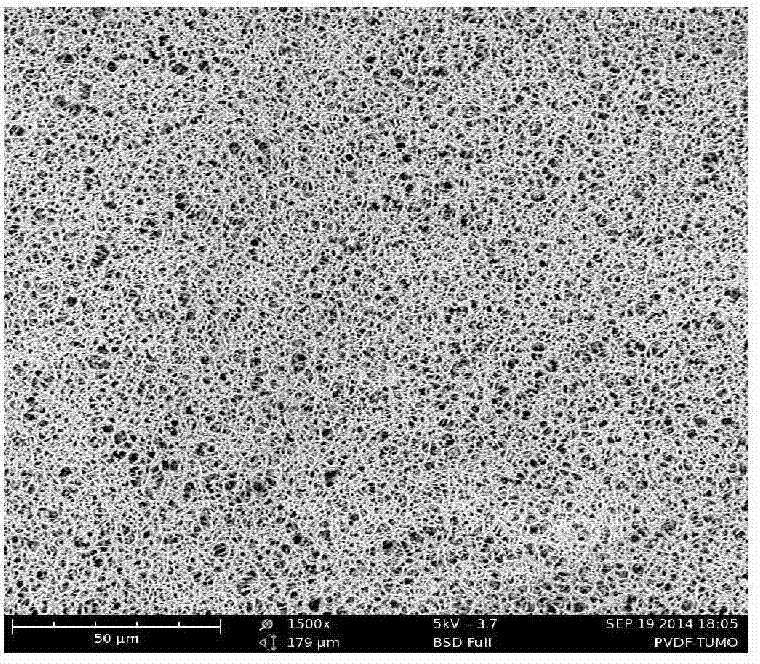

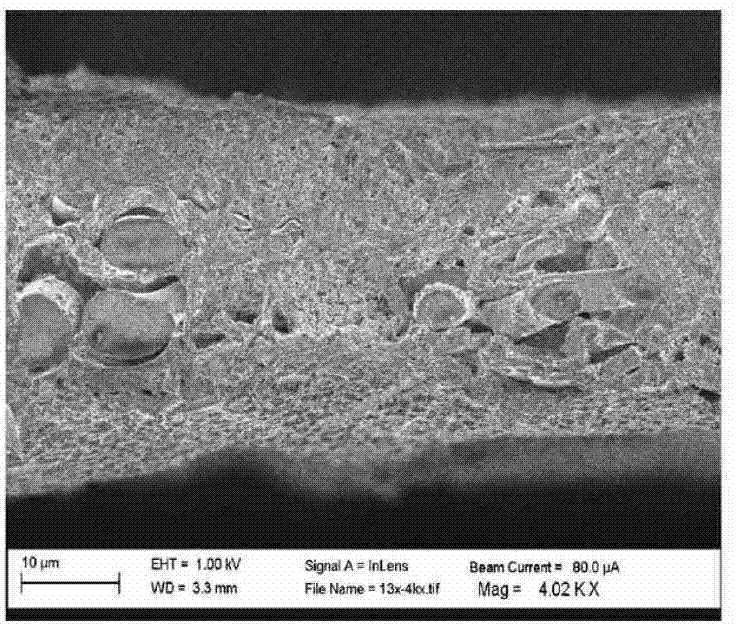

[0045] 3) Preparation of polymer porous coating by phase transfer method: PVDF-HFP (Arke...

Embodiment 3

[0047] 1) Preparation of electrospinning solution: Preparation of electrospinning solution: dissolve polyacrylonitrile (PAN) in NMP, the mass volume ratio concentration of polyacrylonitrile is 10wt%, and the viscosity of the polyimide solution is measured to be 1000mPa. S.

[0048] 2) Electrospinning: The prepared polyacrylonitrile solution electrospinning solution is passed through a nanofiber spinning machine to carry out single-sided continuous electrospinning on a PP non-woven fabric substrate to obtain a PAN / PP nanofiber composite film. The conditions of electrospinning described above are: temperature 30°C, positive voltage 20kV, negative voltage negative 30kV, spinning speed 5g per minute per meter width;

[0049] The composite membrane obtained after the spinning is completed is subjected to post-processing: first, it is formed by hot pressing with a roller at 100° C., and then dried in an oven at 120° C. for 4 minutes.

[0050] 3) Preparation of polymer porous coatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com