Battery core with external sheath of wound lithium-ion battery

A lithium-ion battery, winding technology, which is applied in the direction of battery box/outer, winding/folding electrodes, small-sized batteries/battery packs, etc. Insulation layer damage, poor process efficiency and other problems, to achieve the effect of simple structure, increased capacity and cycle life, and avoid unintentional crashes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

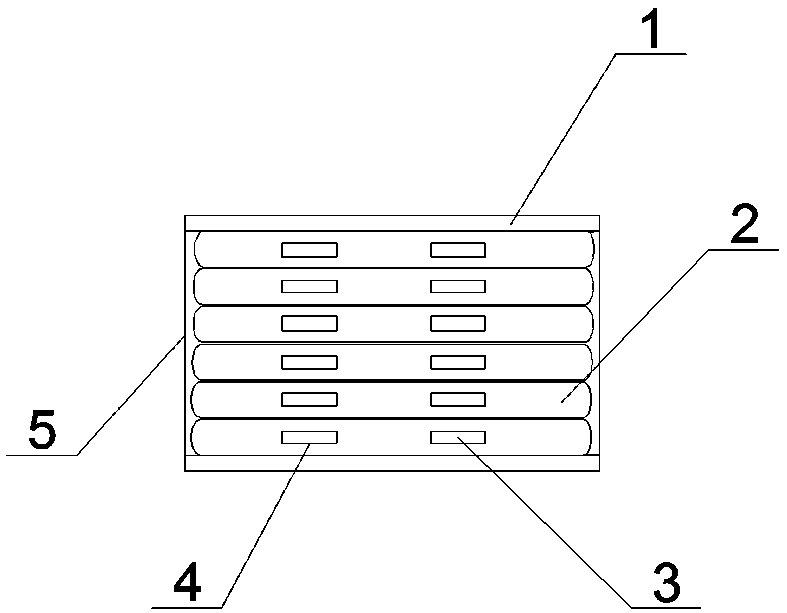

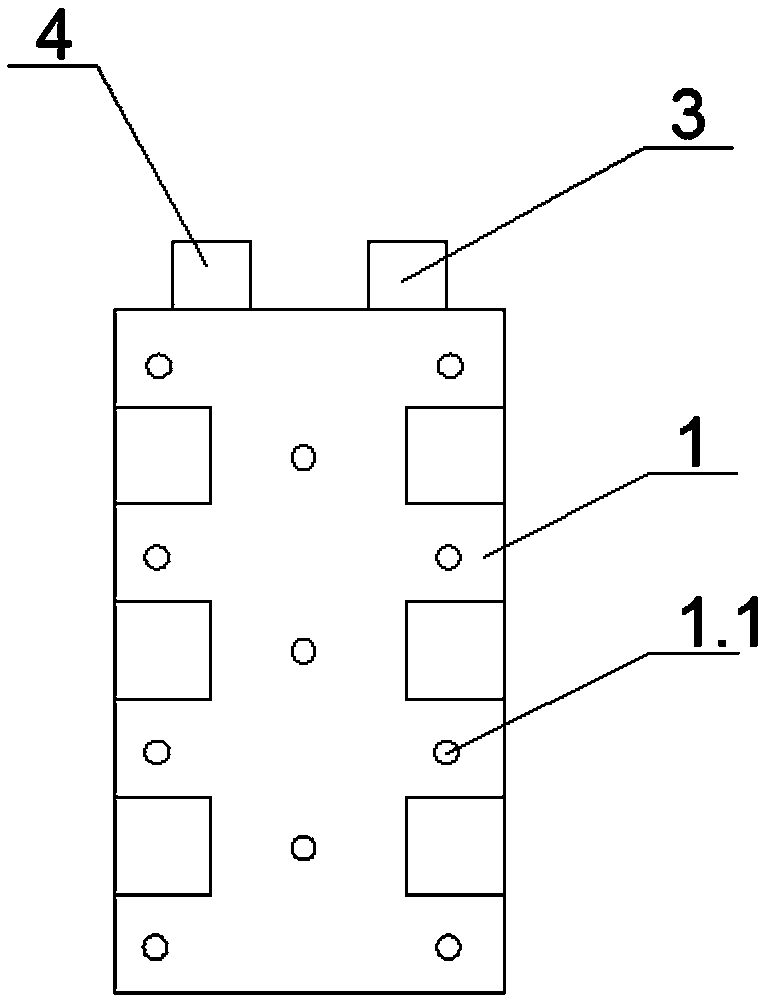

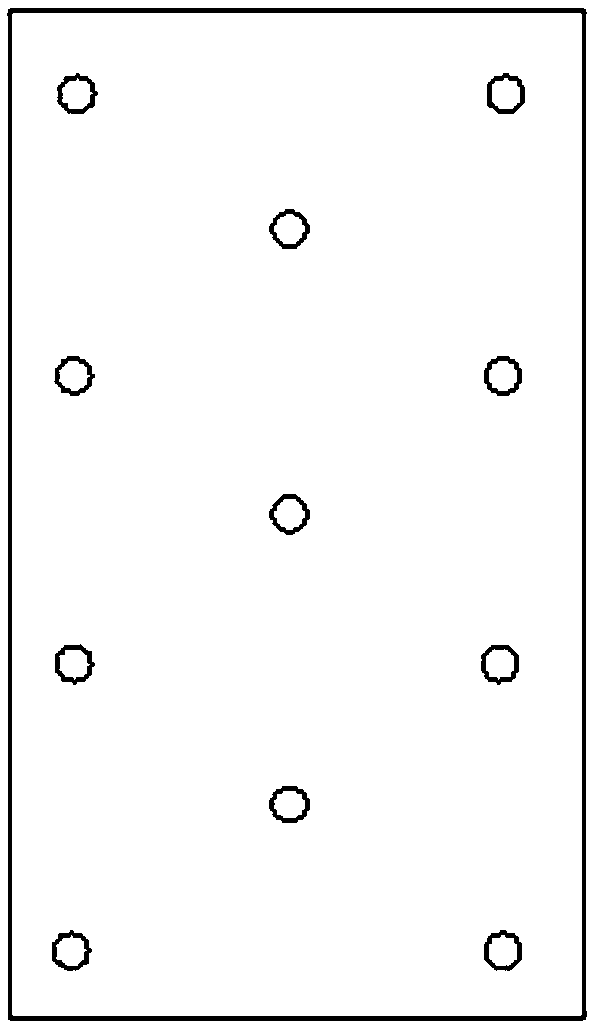

[0016] attached figure 1 The battery core of the external sheath of the wound lithium ion battery shown is a composite component, which includes a pressing plate 1 , a winding core 2 , a positive electrode sheet 3 , a negative electrode sheet 4 and an adhesive tape 5 . According to the structure of the winding battery, the positive electrode sheet 3 and the negative electrode sheet 4 arranged alternately are inserted in the cavity of the winding core 2, and the winding core 2 adopts a stacked installation structure. The pressing plate 1 is a component designed by the present invention, and it is used to clamp the stacked winding core 2 on the one hand, and is used to protect the battery core and pack the casing on the other hand. In this embodiment, the pressing plate 1 is 2.0 mm thick and made of PP material. The long and wide sides o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com