Separator having porous coating layer, method for manufacturing the same and electrochemical device having the same

Inactive Publication Date: 2010-12-16

TORAY BATTERY SEPARATOR FILM

View PDF13 Cites 72 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

[0006]The present invention is designed in consideration of the above problems, and therefore it is an object of the invention to provide a separator capable of improving high temperature cycle performance and discharge characteristics of an electrochemical device due to increased impregnation and insolubility to electrolyte as well as controlling an electric short circuit between a cathode and an anode due to excellent thermal stability even when the electrochemical device is overheated. The present invention also provides a method for manufacturing the separator and an electrochemical device having the separator.Technical Solution

Problems solved by technology

However, a polyolefin porous substrate shows extreme thermal shrinking behavior at a temperature of 100° C. or above due to the features of its material and its manufacturing process such as elongation, so there may occur an electric short circuit between cathode and anode.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example 2

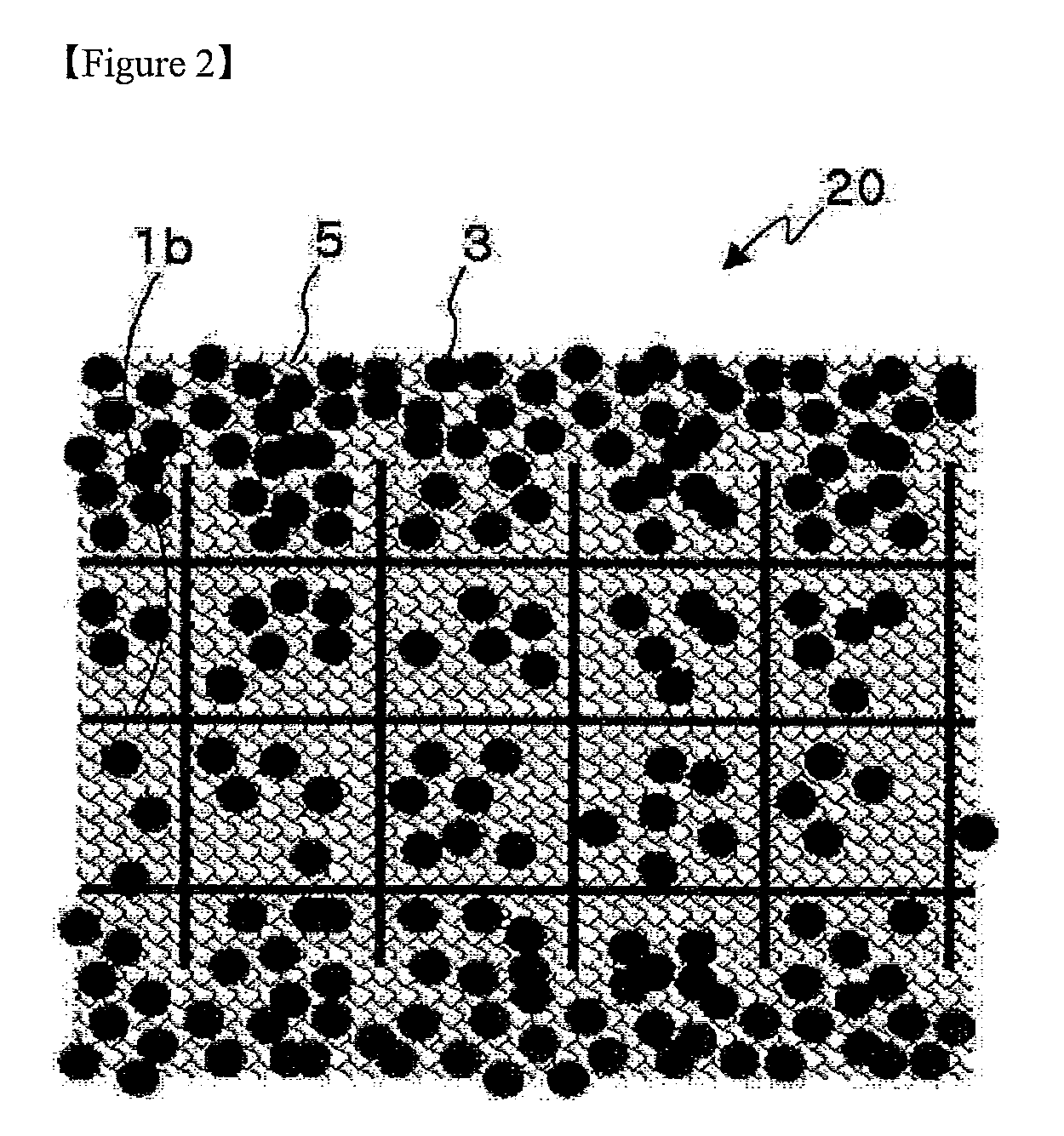

[0057]A separator and a lithium secondary battery were manufactured in the same way as the example 1, except that a polyethyleneterephthalate non-woven fabric with a thickness of about 20 μm was used as a porous substrate. The made separator and porous coating layer had a pore size of 0.6 μm or less and porosity of about 55%.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Porosity | aaaaa | aaaaa |

Login to View More

Abstract

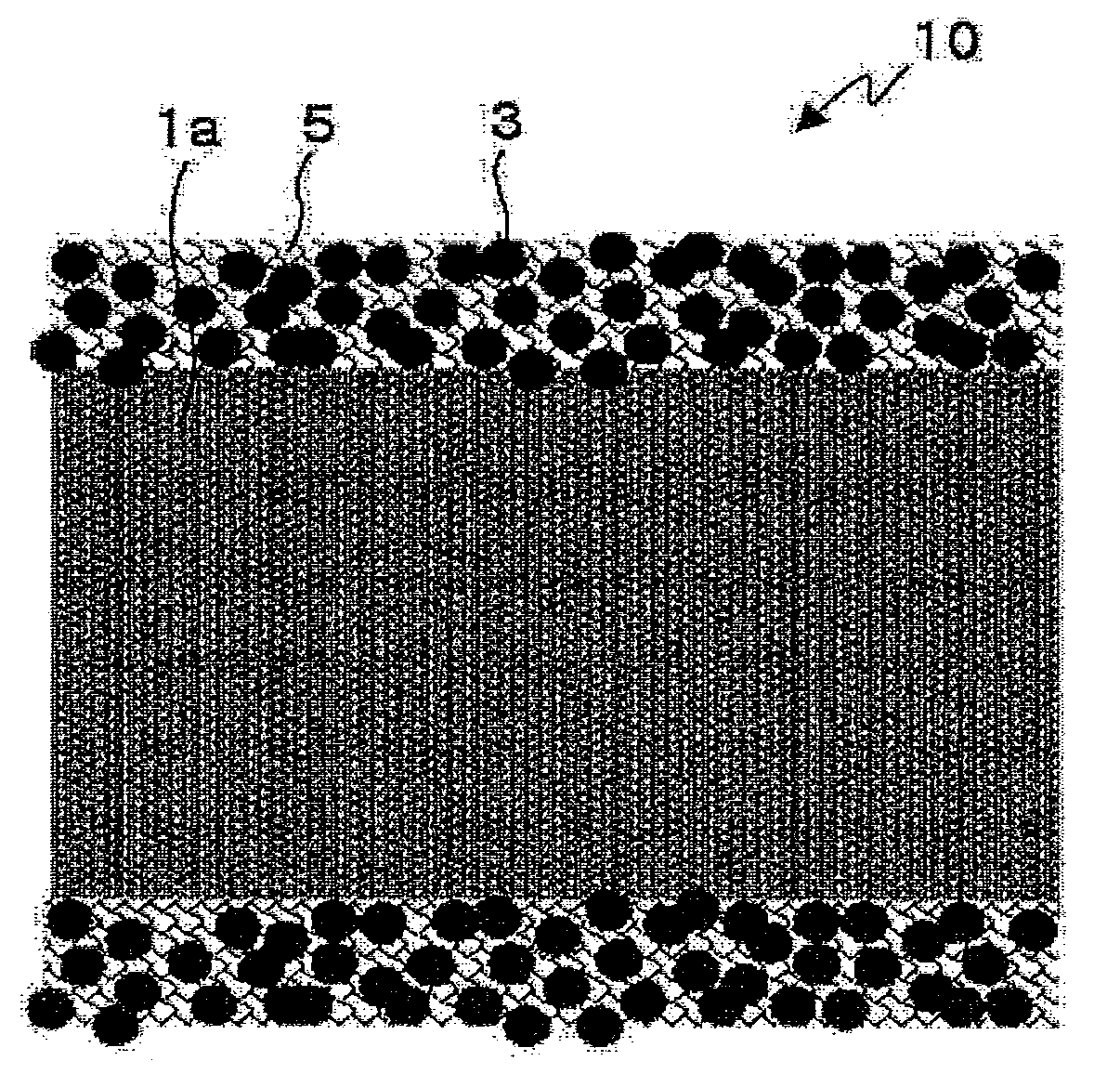

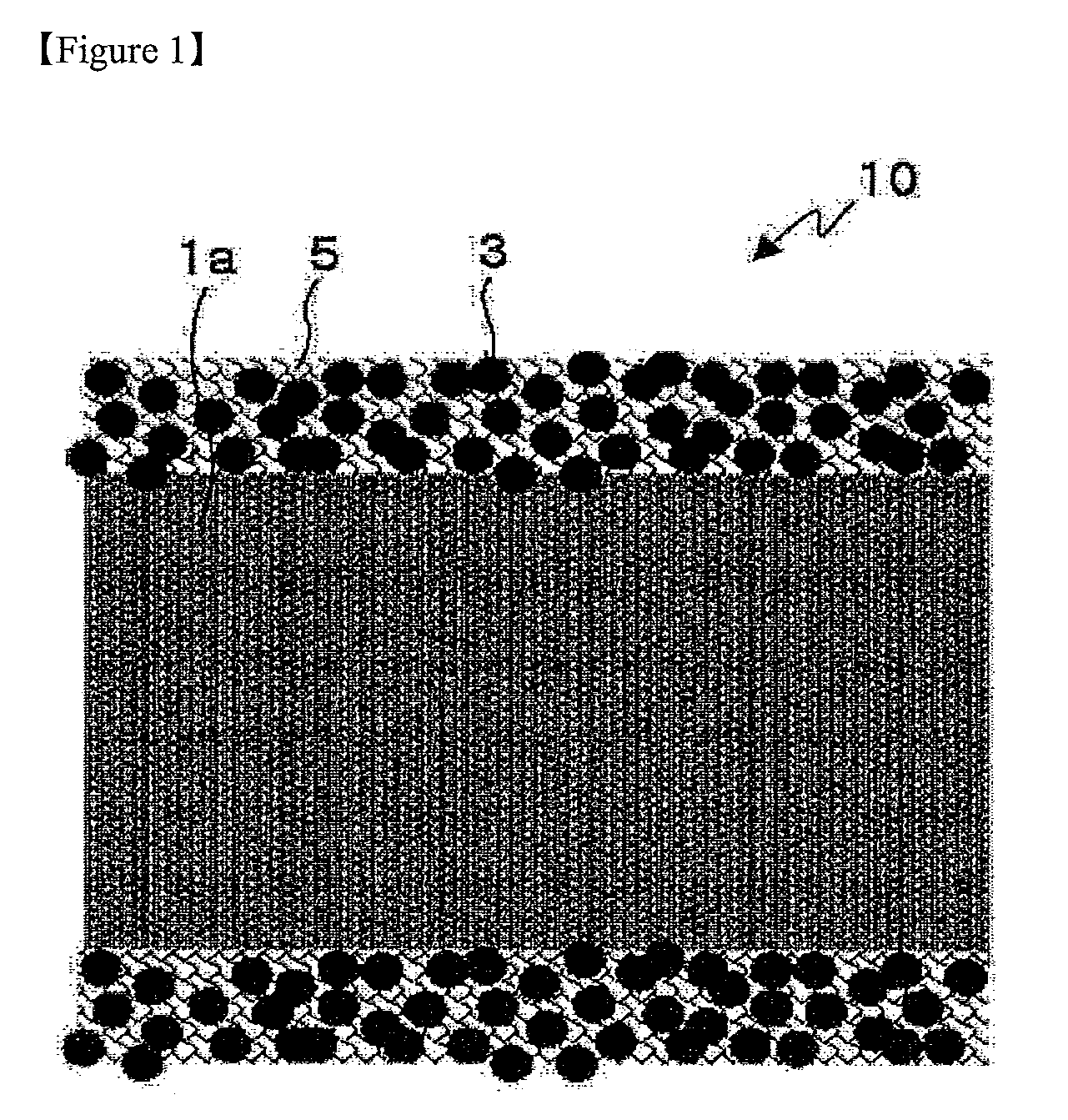

A separator includes a porous substrate having a plurality of pores; and a porous coating layer formed on at least one surface of the porous substrate and made of a mixture of a binder and a plurality of inorganic particles, wherein the binder includes a crosslinked binder. This separator may improve high temperature cycle performance, discharge characteristics and thermal resistance of an electrochemical device since the separator exhibits improved insolubility and impregnation to electrolyte and improved thermal resistance.

Description

TECHNICAL FIELD[0001]The present invention relates to a separator of an electrochemical device such as a lithium secondary battery and an electrochemical device having the same, and more particularly to a separator having a porous coating layer made of a mixture of inorganic particles and binder polymer and formed on a surface of a porous substrate and an electrochemical device having the same.BACKGROUND ART[0002]Recently, there has been an increasing interest in energy storage technology. Batteries have been widely used as energy sources in the fields of cellular phones, camcorders, notebook computers, PCs and electric cars, resulting in intensive research and development into them. In this regard, electrochemical devices are one of the subjects of great interest. Particularly, development of rechargeable secondary batteries has been the focus of attention, among which the development of a secondary chargeable / dischargeable battery is most interested.[0003]Among currently used seco...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01M2/16H01M2/18B05D5/12H01M50/403H01M50/414H01M50/417H01M50/454H01M50/491

CPCH01M2/1653H01M10/052H01M2/166H01M2/1686H01M2/145H01M10/0525H01M10/0583Y02E60/10H01M50/446Y02P70/50H01M50/417H01M50/403H01M50/454H01M50/414H01M50/491H01M10/02C08J5/22H01M50/449H01M50/443H01M50/451H01M50/457H01M50/489

Inventor KIM, JONG-HUNLEE, SANG-YOUNGPARK, PIL-KYUHONG, JANG-HYUKSHIN, BYOUNG-JINKIM, IN-CHUL

Owner TORAY BATTERY SEPARATOR FILM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com