Manufacturing method of special-shaped spring

A technology of special-shaped springs and manufacturing methods, which is applied in the direction of manufacturing springs from wires, other household appliances, household appliances, etc., can solve problems such as inequality, non-synchronization, lack of low-cost, high-precision effective manufacturing methods for special-shaped springs, etc., to achieve processing Guaranteed precision and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

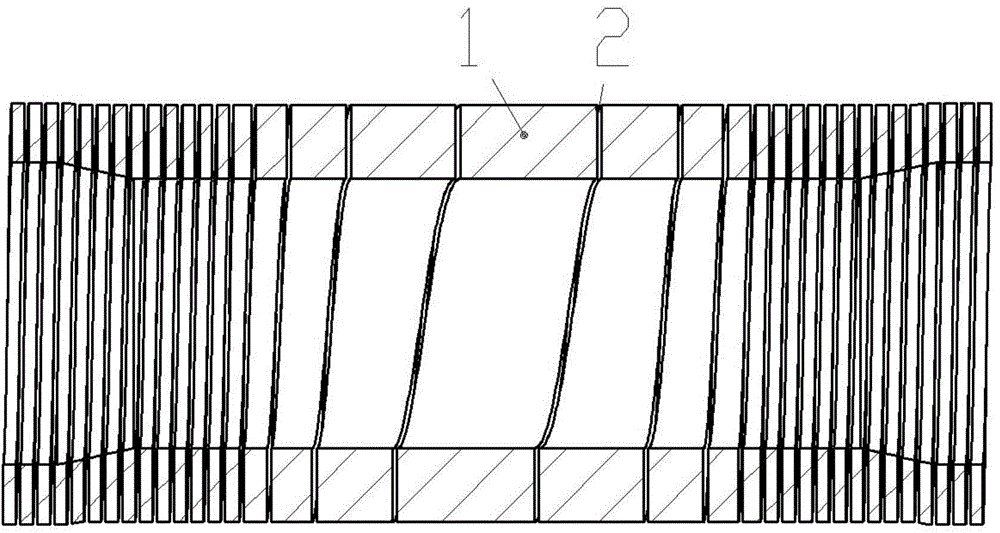

[0032] see figure 1 , the figure shows that the two ends are of equal pitch, and the number of helical turns of equal pitch at both ends is equal, and the middle part of the spring is a variable-pitch variable-section special-shaped spring. The inner and outer diameters of the two ends of the variable cross-section special-shaped spring product 1 are equal and slightly larger than the inner and outer diameters of the middle part, and the changes in the inner and outer diameters are not equal and not synchronized, forming unequal diameter spring coils. Set the value of each parameter according to the specific design requirements of the application. In this example figure 1 The number of helical coils at both ends of the spring shown is 14, the pitch is 5mm, the outer diameter of the two ends is 44mm, the inner diameter is 28mm, the spring helical gap 2 is 0.5mm, and the pitch gradually increases toward the middle of the spring.

[0033] According to the technical solution of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com