Saw grinding belt and processing method

A processing method and grinding belt technology, which are applied in metal processing equipment, manufacturing tools, grinding devices, etc., can solve the problems of only sawing and single tasks, and achieve the goals of improving efficiency, simplifying procedures, and high grinding precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

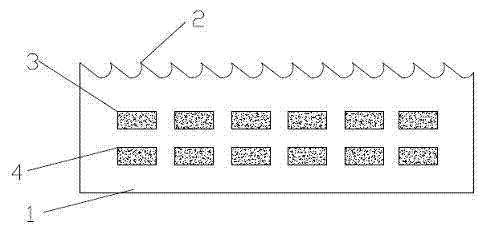

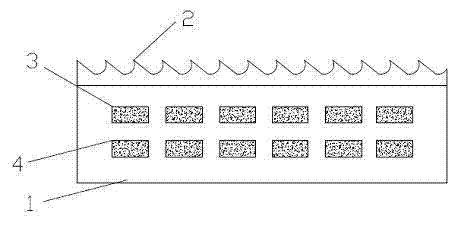

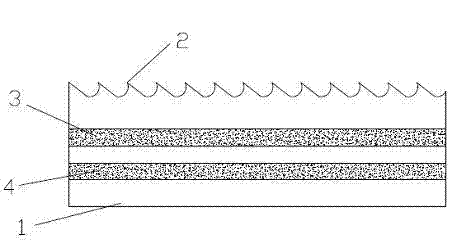

[0029] like Figures 1 to 4 As shown, the saw grinding belt of the present invention includes a band saw blade main body 1 and a sawtooth 2 opened on one side of the band saw blade main body 1, and an abrasive layer is attached to the surface of the band saw blade main body 1, and the abrasive layer includes an upper grinding layer 3 and a lower grinding layer. 4. The thickness of the upper grinding layer 3 is increased by 0.06 mm on the basis of the width of the original saw slit (saw path generated by the separation of teeth between the saw blades), and the thickness of the lower grinding layer 4 is increased by 0.08 mm on the basis of the original saw slit width. .

[0030] The upper grinding layer 3 and the lower grinding layer 4 are respectively two discontinuous rectangular block structures arranged up and down or two continuous long strip structures arranged up and down. When it is a rectangular block structure, the length and width of the rectangular blocks are: 9cm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spacing | aaaaa | aaaaa |

| Upper and lower spacing | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com