Reference hole arrangement method

A datum hole and measurement datum technology, applied in aircraft assembly, measuring devices, instruments, etc., can solve the problems of inability to accurately reflect the assembly state of parts and high measurement complexity, reduce the measurement complexity, improve the hole position accuracy, The effect of reducing the number of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

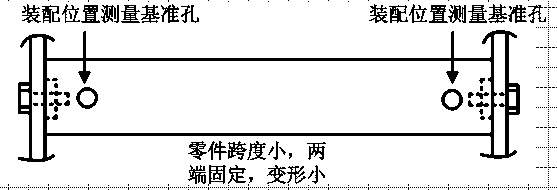

[0027] Such as figure 1 As shown, when the measured maximum deformation of the part is , the hole position error assigned to the hole position correction link through the tolerance is , then when the deformation of the part is small, satisfying When , it is considered that the hole position accuracy at the position with the largest deformation can still meet the hole-making requirements. At this time, the influence of the deformation of the part itself on the hole-making hole position accuracy is not considered, and only the influence of the assembly position of the part on the hole-making hole position accuracy is considered. Therefore, it is only necessary to arrange datum holes at both ends of the part.

Embodiment 2

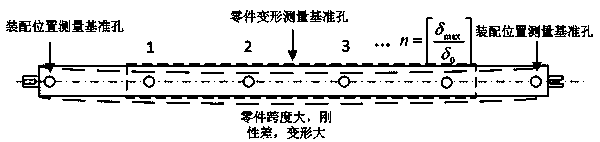

[0029] When the deformation of the part is large and meets the requirement, if the deformation of the part is large in the local area of the part, if the influence of the deformation of the part is not considered, the hole position made by automatic hole making will not meet the hole position accuracy requirements. At this time, it is first necessary to arrange reference holes at both ends of the part to measure the assembly position of the part, and secondly arrange reference holes between the reference holes at both ends for measuring the deformation of the part, the number of which is:

[0030] ;[] stands for rounding

[0031] After this arrangement, no need to consider the deformation of the part between any two deformation reference holes, it can also meet the accuracy requirements of the hole making hole, and achieve the purpose of using a small number of reference holes to reflect the assembly deformation of the part, such as figure 2 shown.

Embodiment 3

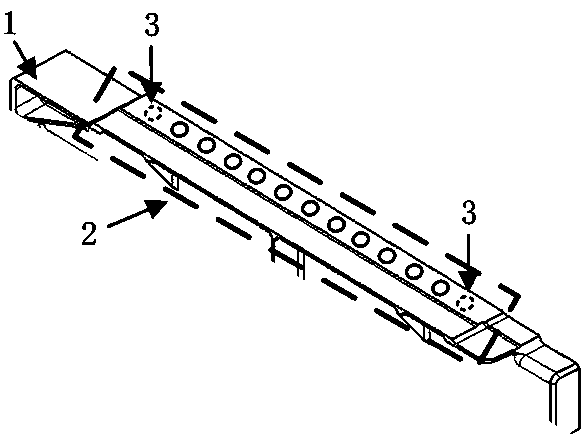

[0033] Such as image 3 As shown, in a digital assembly system, a laser tracker is used to measure the position of the reference hole. The product requires the accuracy of the hole position to be ±0.6mm, of which the accuracy of the reference hole itself is ±0.2mm, the measurement accuracy of the laser tracker is ±0.05mm, and the accuracy assigned to the hole position correction link is ±0.35mm . After using the laser tracker to sample and fit the part shape at multiple points, the maximum deformation of a certain upper girder is 0.2mm, and the maximum deformation of a certain sheet metal frame is 0.9mm.

[0034] For the upper girder, due to , it is only necessary to arrange the assembly position measurement reference holes at both ends of the part.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com