As-fired coal quality online monitoring system and method for real-time operation control

A real-time operation and monitoring system technology, applied in the direction of measuring devices, fuel oil testing, transportation and packaging, etc., can solve the problems of reduced input costs, structural limitations of coal loading belt scales, no sampling device, etc., and achieve the goal of improving the accuracy of calibration positions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

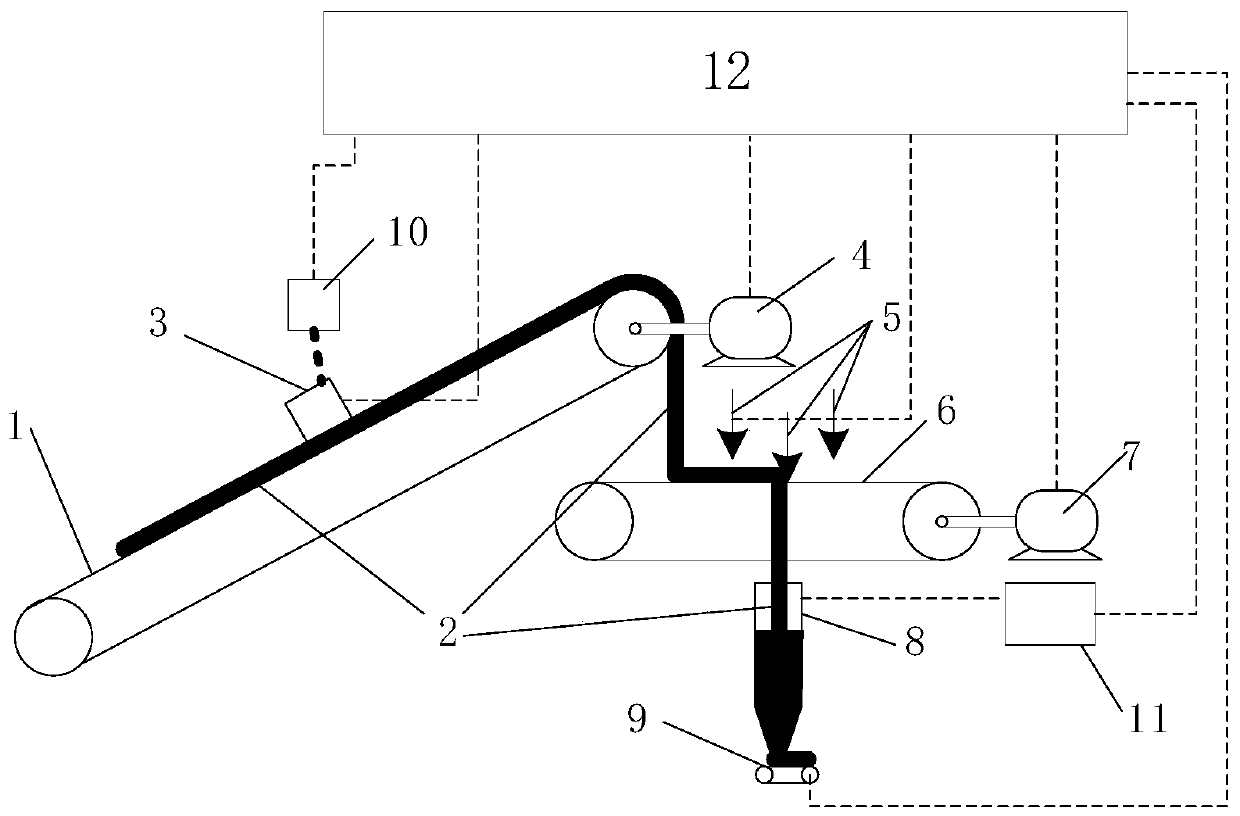

[0028] Such as figure 1 As shown, the present invention is used for real-time operation control coal quality on-line monitoring system, including a coal loading belt 1 driven by a coal loading belt motor 4 and a coal loading belt motor 4, a fuel coal 2 to be transported, and installed in a The sampling machine 3 on the coal loading belt, the horizontal belt 6 for distributing coal bunkers after going through the belts and distributors at all levels, the horizontal belt motor 7 that drives it to run, the multiple coal plows 5 installed on the horizontal belt 6, and the Coal machine 9, coal bunker 8 at the entrance of the coal feeder, coal quality on-line detection device 10 for receiving the coal sample produced by the sampling machine 3 for coal quality analysis, and receiving the signal of the material level sensor installed on the coal bin 8 at the coal feeder inlet The material level change classification correction filter module 11 used for material level correction, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com