Workpiece internal-external circle concentricity lathe turning tooling and using method thereof

A technology of lathe processing and coaxiality, which is applied in the direction of metal processing equipment, metal processing machinery parts, positioning devices, etc., can solve the problems of inaccurate clamping, low pass rate of workpiece processing, and high processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

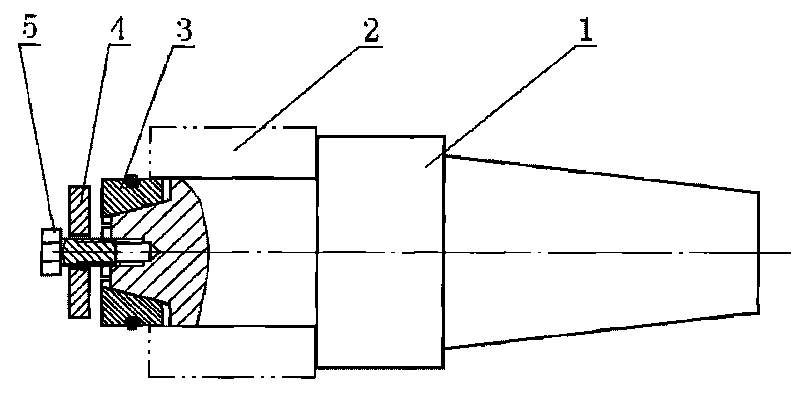

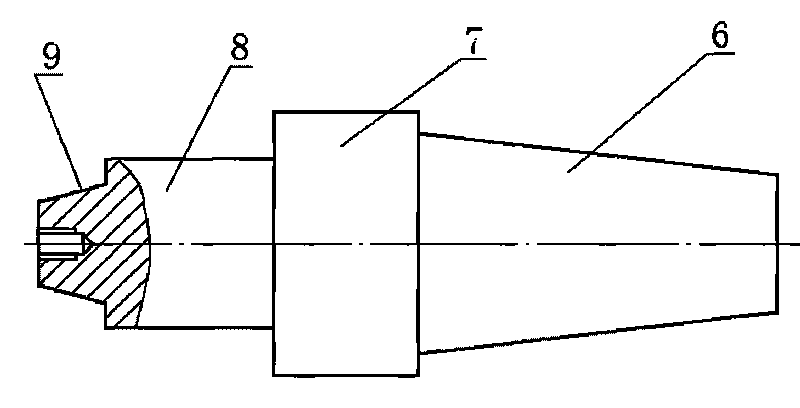

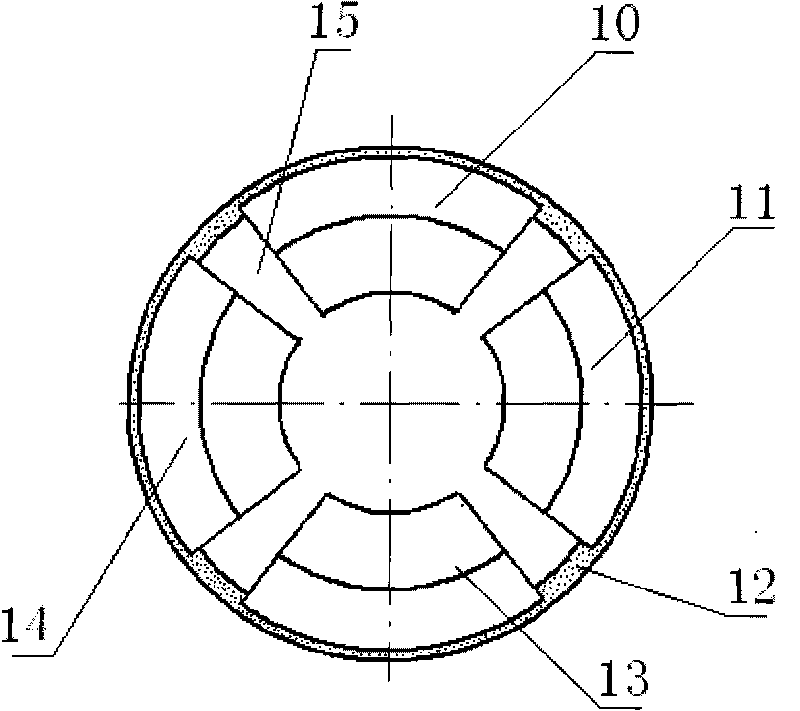

[0018] Such as figure 1 , figure 2 , image 3 As shown, a lathe processing tool for the coaxiality of the inner and outer circles of the workpiece is composed of a clamping body 1, a tensioner 3, a baffle 4 adjacent to the tensioner 3, and a set bolt 5 passing through the baffle 4, The clamping body 1 is composed of the machine tool spindle matching section 6, the transition section 7, the workpiece installation section 8 and the tapered section 9, wherein the transition section 7 has the largest diameter, and the end of the tapered section 9 has a The bolt hole, the tensioner 3 is composed of the first tensioner 10, the second tensioner 11, the third tensioner 13, the fourth tensioner 14 and the elastic ring 12, the first tensioner 10, the second tensioner The second tensioning block 11, the third tensioning block 13, and the fourth tensioning block 14 have the same structure, and all have a high-precision inner ring surface that is compatible with the tapered section 9 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com