Punching mould and punching method suitable for labtop keyboard frame

A notebook computer and stamping die technology, applied in the field of stamping dies and stamping, can solve the problems of high stamping force of metal parts, collapse angle of keyboard hole, difficulty in meeting high requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

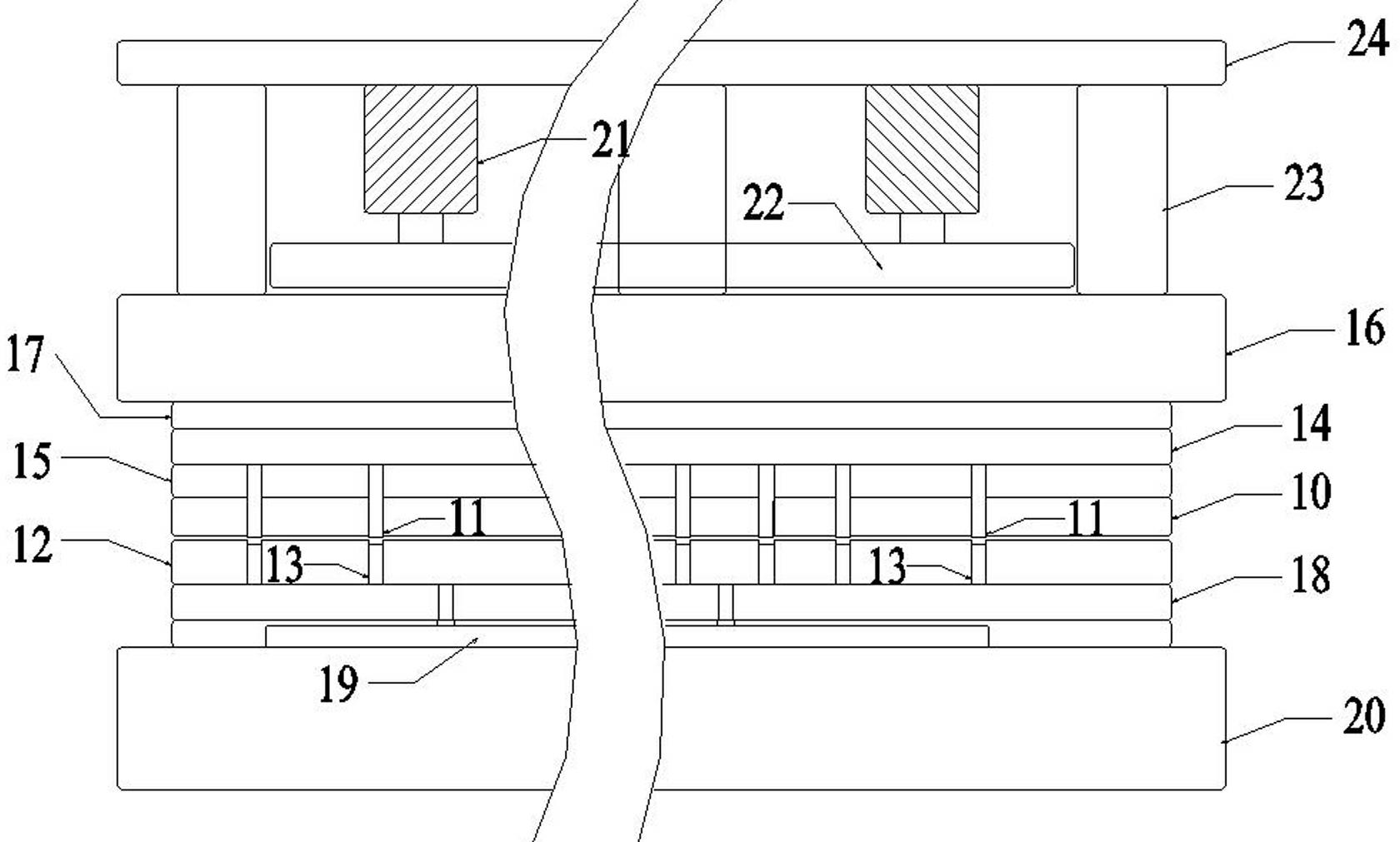

[0035] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

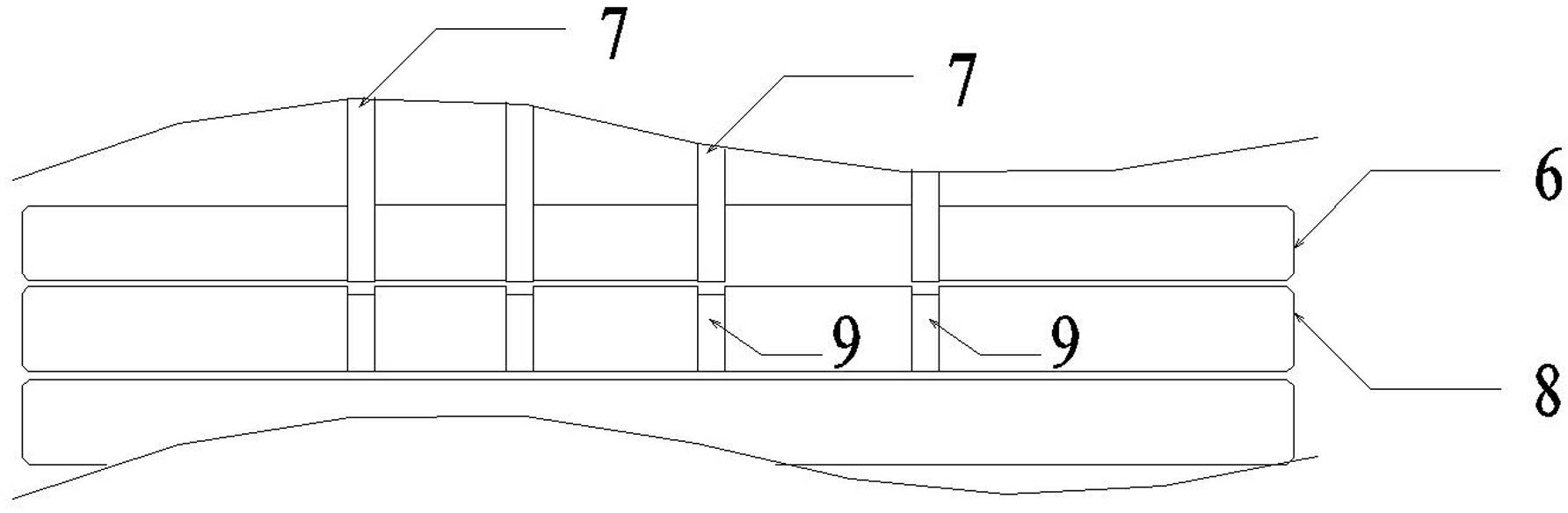

[0036] A stamping die suitable for laptop keyboard frames, including: a set of blanking dies for blanking, multiple sets of rough punching dies for rough punching and preprocessing, and a set of fine blanking for final finishing mod.

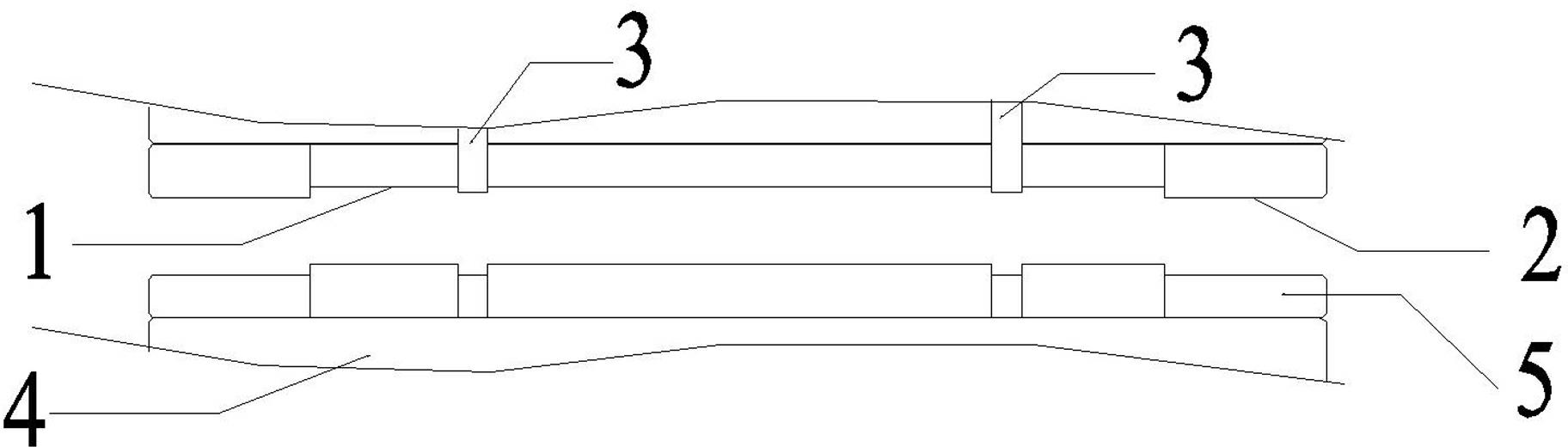

[0037] refer to figure 1, the blanking module includes: a blanking and upper stripping plate 1 for stripping and pressing materials; a blanking punch set arranged in the blanking and upper stripping plate 1 for punching materials, the blanking punch set It includes a blanking punch 2 for blanking the periphery of the material to form the border around the keyboard and a punching punch 3 for punching out holes on the keyboard other than the keyboard hole; it is arranged under the blanking upper stripper plate 1 The blanking lower template 4 is used to fix the lower mold parts; the blanking lower mold that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com