Method for producing titanium strip by adopting conventional hot continuous rolling machine set

A technology of hot continuous rolling and titanium strip, applied in metal rolling, tension/pressure control, roll speed control, etc., can solve the problems of coil weight limitation and high production cost, improve quality, reduce production cost, and advanced control system Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

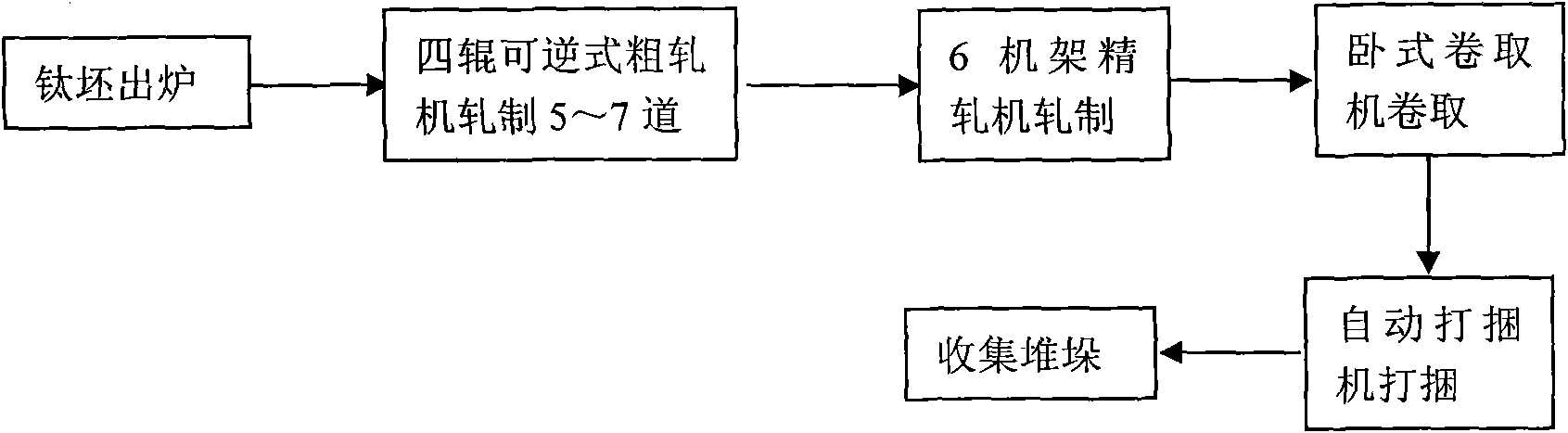

Method used

Image

Examples

Embodiment 1

[0026] The 180*1000*8000mm titanium billet is heated to 800-900°C and released from the furnace. It is transported to the four-roll reversible roughing mill at a speed of about 1.5m / s through the roller table and the roller table before rough rolling. Rolling is carried out in 5 passes. The 30mm thick intermediate slab is formed for the first time, and the rolling speed is 1.2-4m / s. After the roller table is sent to the flying shear to remove the irregular part of the head, it enters the 6-stand finishing rolling unit for rolling, and the finishing rolling temperature is 750~ 850°C.

[0027] There are 5 sets of hydraulic looper devices (namely H1~H5) between the stands of the finishing rolling mill. The height adjustment system makes the rolling mill automatically adjust the speed, and through the tension adjustment system, the titanium strip is rolled under the state of slight tension and constant tension. The tension is set at 4-8MPa, and the titanium strip of 4.5*1000mm is ...

Embodiment 2

[0029] Others are the same as in Example 1, the difference is that the raw material size is 240*1200*10000mm, the finished product size is 20*1200mm, the thickness of the intermediate billet is 50mm, the titanium billet is heated to 800-850°C and released, and the rolling speed of the roughing mill is 1.2-3m / s, the finish rolling start temperature is 750~800℃. The tension of the finish rolling unit is set at 6-8MPa, and the titanium strip of the required size is rolled; the final rolling temperature is 650-700°C, and the rolling speed is 3m / s; the finished titanium strip is transported to the horizontal coil through the layer cooling roller table The take-up machine coils into coils, the coil weight is 5-15 tons, the coiling temperature is 550-600 ℃, and the coiling tension is 5-8MPa.

Embodiment 3

[0031] Others are the same as in Example 1, the difference is that the raw material size is 160*1000*11000mm, the finished product size is 3*1000mm, the finished titanium billet is heated to 850-900°C and released, the rolling speed of the rough rolling mill is 2-4m / s, the finishing The rolling start temperature is 750-800°C. The tension of the finish rolling unit is set at 5-8MPa, and the titanium strip of the required size is rolled; the final rolling temperature is 650-700°C, and the rolling speed is 8m / s; the finished titanium strip is transported to the horizontal coil through the layer cooling roller table The take-up machine coils into coils, the coil weight is 5-15 tons, the coiling temperature is 550-580 ℃, and the coiling tension is 8-10 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com