Method for preparing aluminum-magnesium ultrafine crystal composite plate with multilayer structure

A multi-layer structure, ultra-fine crystal technology, applied in the direction of chemical instruments and methods, metal rolling, layered products, etc., can solve the problems of material matrix performance degradation, difficult product quality, low composite strength, etc., to increase the bonding strength , improve performance, refine the effect of the organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

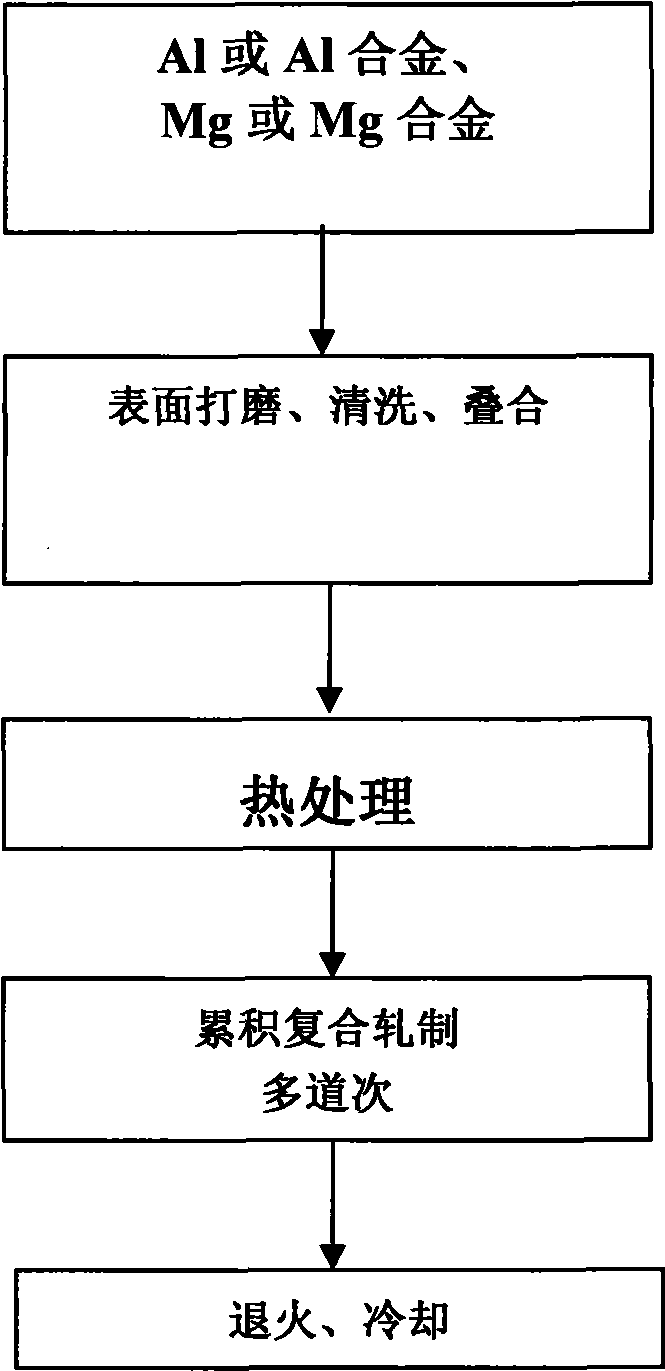

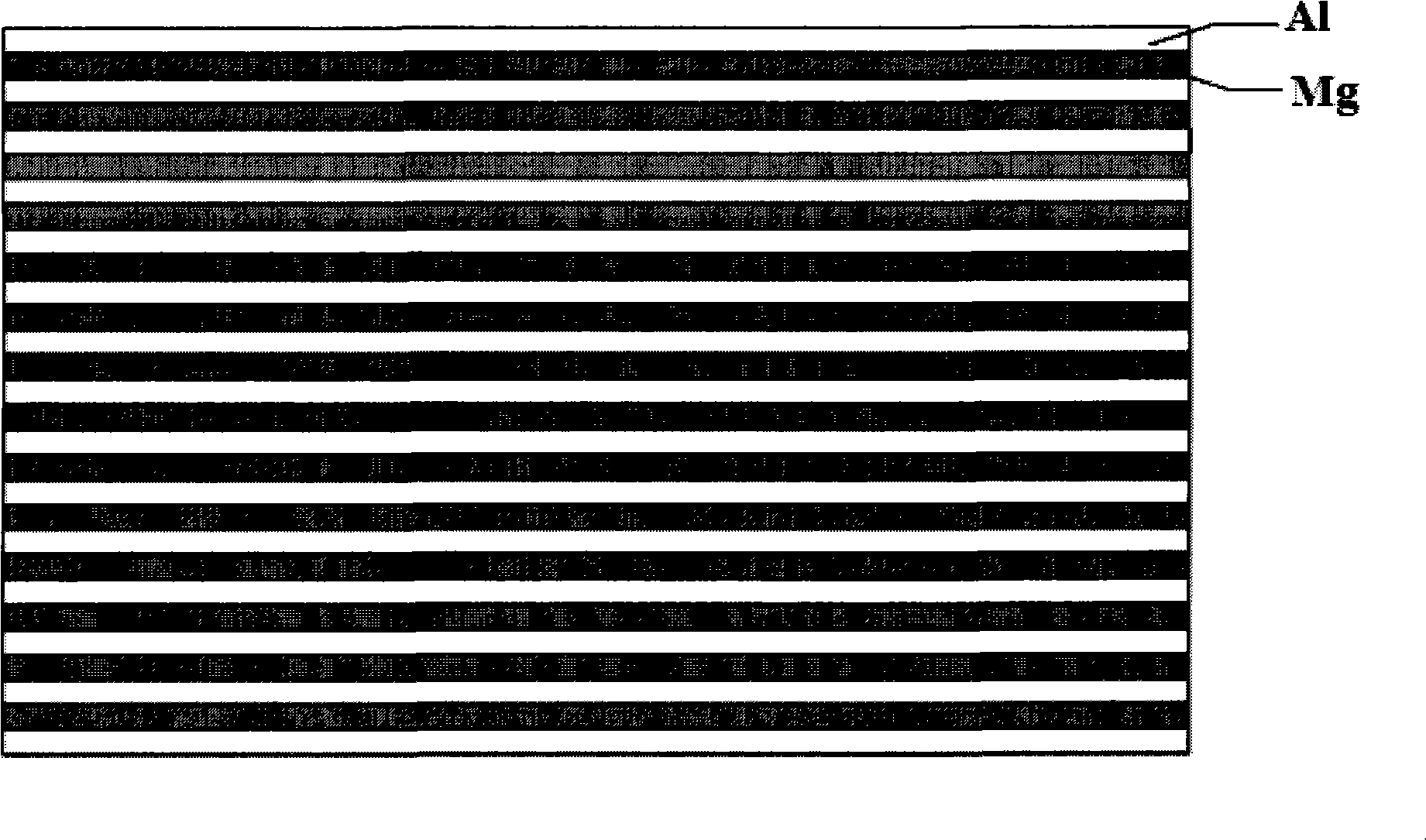

[0019] see figure 1 , the preparation method of the aluminum-magnesium ultrafine-grained multilayer structure composite plate of the present invention selects sheet material Al or Al alloy, Mg or Mg alloy as raw material, and the structural layer of the prepared ultrafine-grain multilayer structure composite plate is successively Al / Mg / Al, or Al alloy / Mg alloy / Al alloy, or Al / Mg alloy / Al; its preparation adopts the method of cumulative clad rolling, specifically implemented according to the following steps:

[0020] 1. Use a wire brush to polish the surface of Al or Al alloy and Mg or Mg alloy plate to make the surface roughness Ra≤12.5μm;

[0021] 2. Clean the surface of the treated plate with acetone or absolute ethanol solution to remove metal shavings and impurities on the surface of the plate;

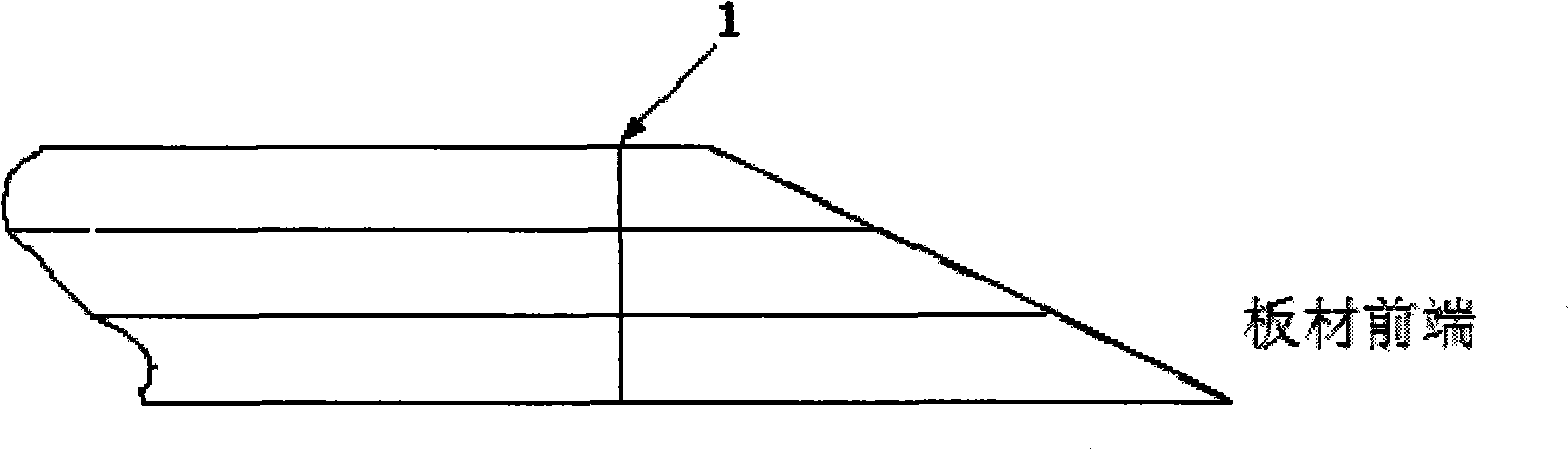

[0022] 3. Put the cleaned Al or Al alloy, Mg or Mg alloy in the order of Al / Mg / Al, or in the order of Al alloy / Mg alloy / Al alloy, or in the order of Al / Mg alloy / Al in order of h...

Embodiment 2

[0033] In this example, the difference between this implementation and Example 1 is that the surface treatment method of the plate is different. Firstly, the oxide on the surface of the plate is removed by chemical method, that is, NaOH, HNO 3 Wash with aqueous solution to remove scale, oil and impurities, and rinse with water; then use a wire brush / feather wheel to polish the surface of aluminum and aluminum alloy panels, magnesium and magnesium alloy panels, and honeycomb panels; finally use acetone or Clean the surface of the plate with anhydrous ethanol solution. Other steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com