Steel plate for large-thickness hydrogen-contacting equipment and its production technology

A hydrogen-facing equipment and large-thickness technology, applied in heat treatment equipment, manufacturing tools, temperature control, etc., can solve problems such as difficult to ensure the performance of steel plates, achieve excellent hydrogen corrosion resistance, good weldability, and improve comprehensive mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

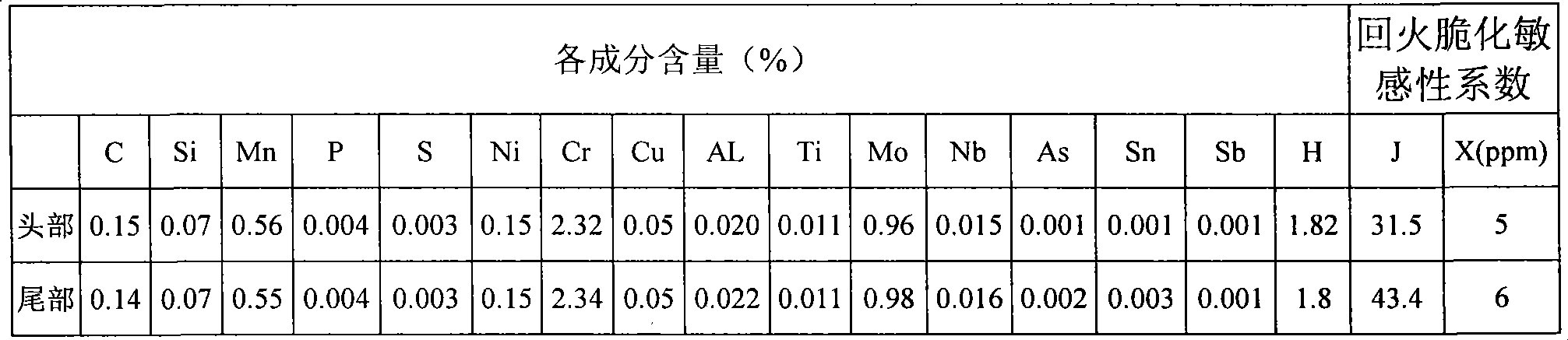

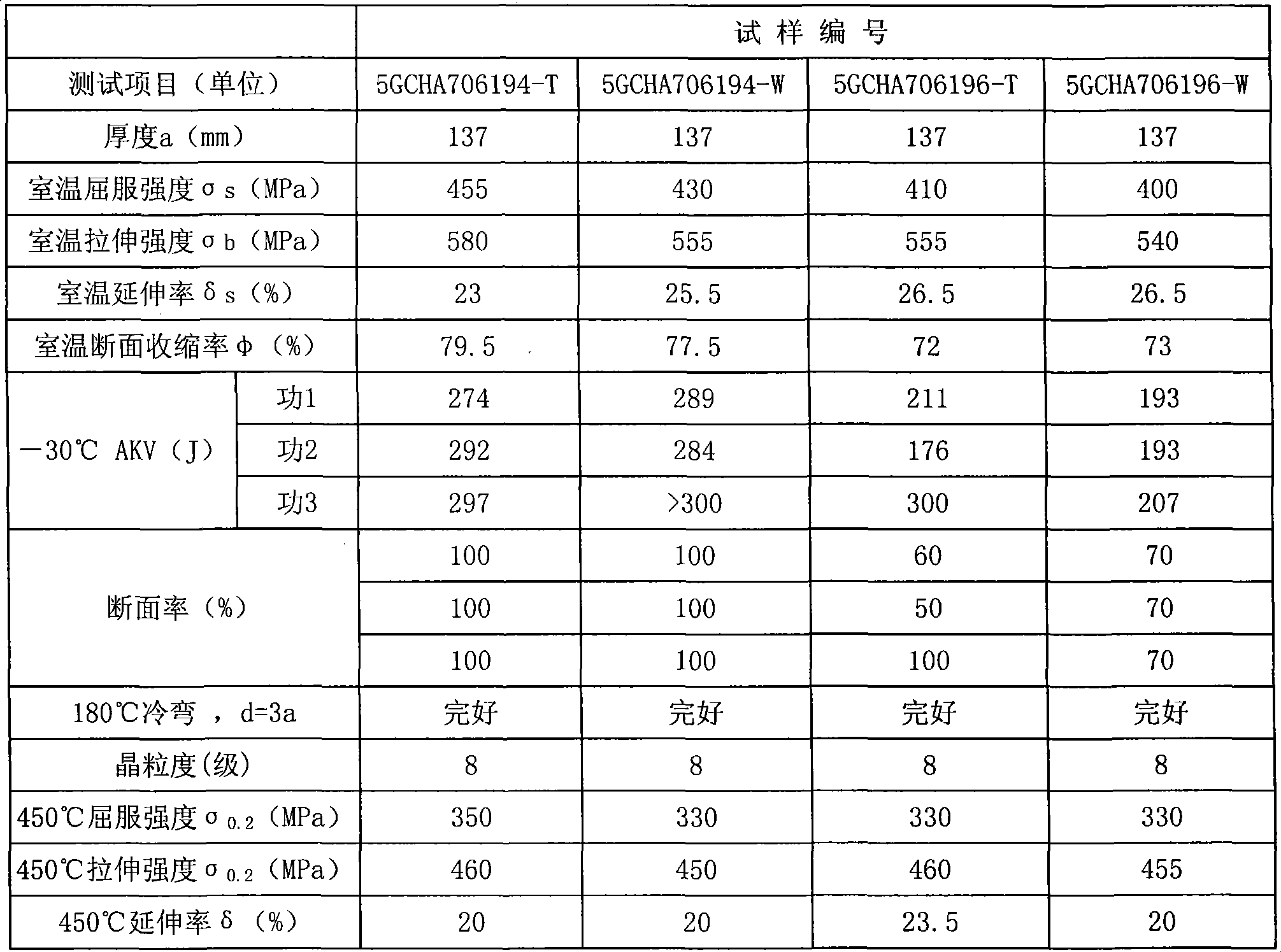

[0024] The actual content of each component of the large-thickness hydrogen-facing equipment steel plate of the present invention is in mass percentage, as shown in Table 1, its thickness is 137mm, and the welding cold cracking index Pcm of the head and tail is respectively 0.37%, 0.36%. The equivalent Ceq is 0.91%.

[0025] Table 1 Contents of each component and temper embrittlement sensitivity coefficient of steel for large-thickness hydrogen-facing equipment

[0026]

[0027] The production method of large thickness steel plate for hydrogen equipment is as follows:

[0028] (1) Smelting process: molten steel is first smelted in an electric furnace, sent to an LF refining furnace for refining, and fed with an Al wire of 300-500m, and when the ladle temperature is ≥1600°C, it is vacuum-treated in a VD furnace;

[0029] (2) Casting process: the temperature is 1555-1565°C after vacuum failure;

[0030] (3) Steel ingot cleaning and heating process: In order to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com