Efficient hot-strength steel welding rod

A heat-strength steel and high-efficiency technology, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of high brittle and hard tendency, hydrogen-induced cracks, delayed cracks, etc., and achieve increased fluidity and impact The effect of improving toughness and increasing the number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

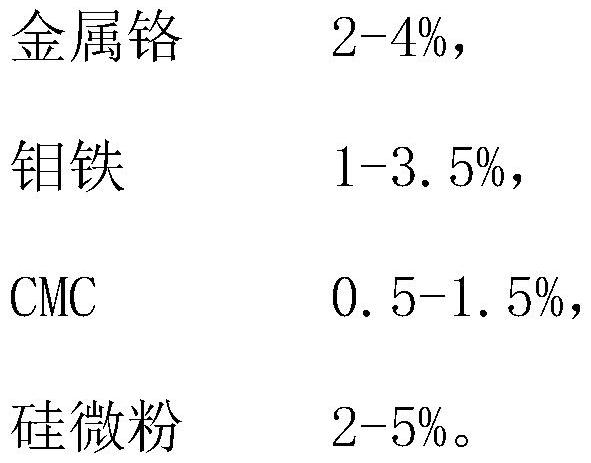

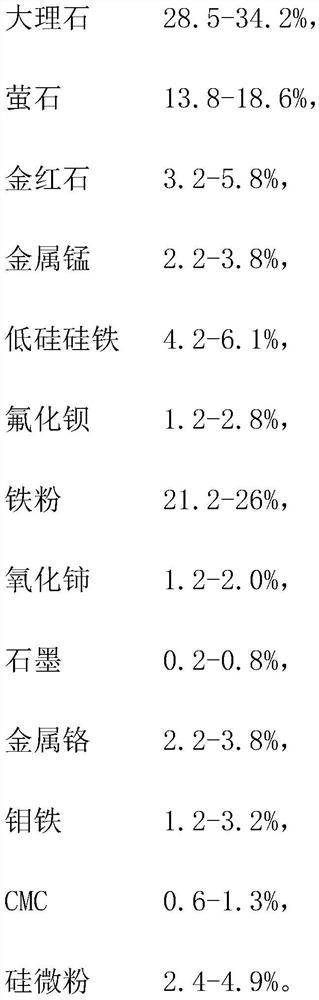

[0033] A high-efficiency heat-strength steel welding rod, the welding wire composition is as shown in Table 1, and the coating composition is as shown in Table 2. Mix the raw materials of the coating evenly, add 20% water glass of coating weight to it, mix well, Send the wet-mixed powder into the hydraulic press, wrap it on the welding core, and bake it at low temperature, medium temperature and high temperature. The concentration of the water glass is 42 degrees Baume; the potassium-sodium ratio of the water glass is 2.5:1. The low temperature baking temperature is 70°C, the medium temperature baking temperature is 130°C, and the high temperature baking temperature is 370°C.

Embodiment 2

[0035] The only difference from Example 1 is that the components of the welding core are shown in Table 1, and the components of the coating are shown in Table 2.

Embodiment 3

[0037] The only difference from Example 1 is that the components of the welding core are shown in Table 1, and the components of the coating are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com