Extra-thick hydrogen present 15CrMoR steel plate and production method thereof

A production method and steel plate technology, applied in heat treatment process control, heat treatment equipment, manufacturing tools, etc., can solve the problems of narrow specification range of 15CrMoR hydrogen-resistant steel plate, inability to meet the market demand for thick plates, and difficulty in ensuring the performance of steel plates, etc., to achieve hydrogen resistance Excellent corrosion resistance, enhanced batching control and smelting operation, and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

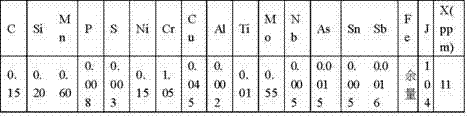

[0020] The extra-thick hydrogen-facing 15CrMoR steel plate of the present invention is characterized in that the steel plate is composed of the following elements in terms of mass percentage: C 0.12-0.17%, Si≤0.20%, Mn0.40-0.70%, P≤0.008%, S≤ Fe and unavoidable impurities.

[0021] The thickness of the extra-thick hydrogen-prone 15CrMoR steel plate is 120-150mm.

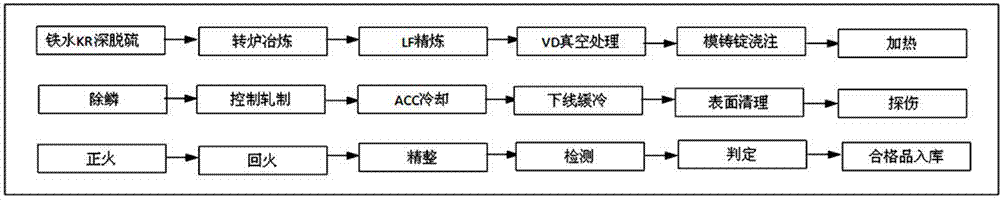

[0022] The production method adopted in the present invention includes: converter smelting, LF refining, vacuum refining, pouring, heating, rolling, controlled cooling, slow cooling and heat treatment.

[0023] The production method of the extra-thick hydrogen 15CrMoR steel plate is characterized in that it comprises the following steps:

[0024] Smelting process: molten steel is first smelted by converter, then sent to LF refining furnace, ladle temperature ≥ 1600 ℃, vacuum treatment in VD furnace.

[0025] Casting process: after the vacuum is broken, the casting temperature is controlled according to 1550-1555°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com