Slab sickle bending control system and method used for roughing mill

A technology of control system and sickle bending, applied in the direction of rolling force/roll gap control, etc., can solve problems such as deviation, insufficient adjustment, excessive adjustment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

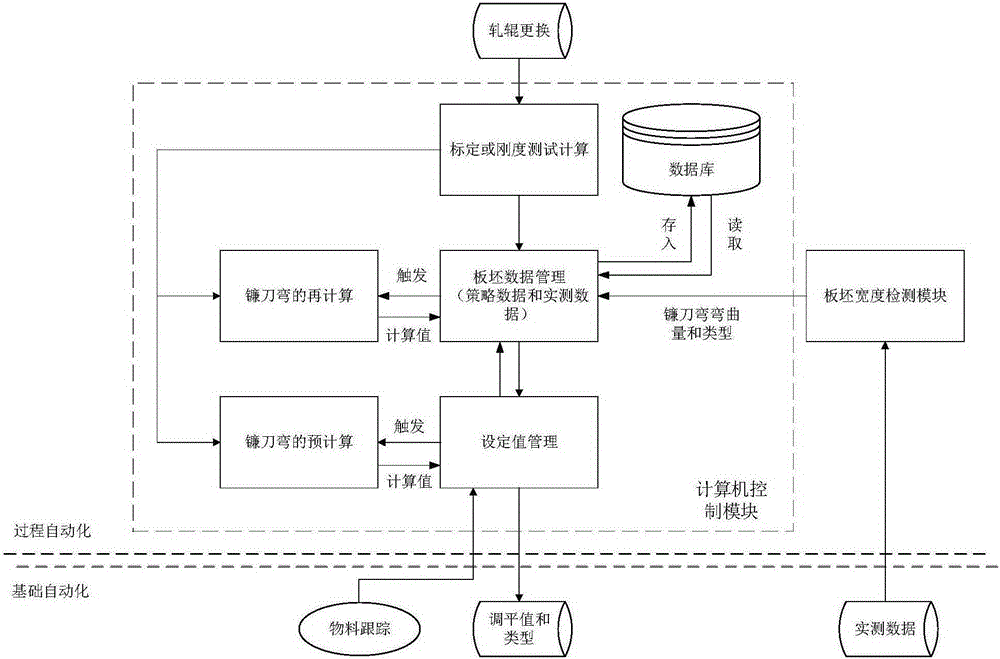

[0048] An embodiment of the present invention provides a slab camber control system for a roughing mill. It contains the following content:

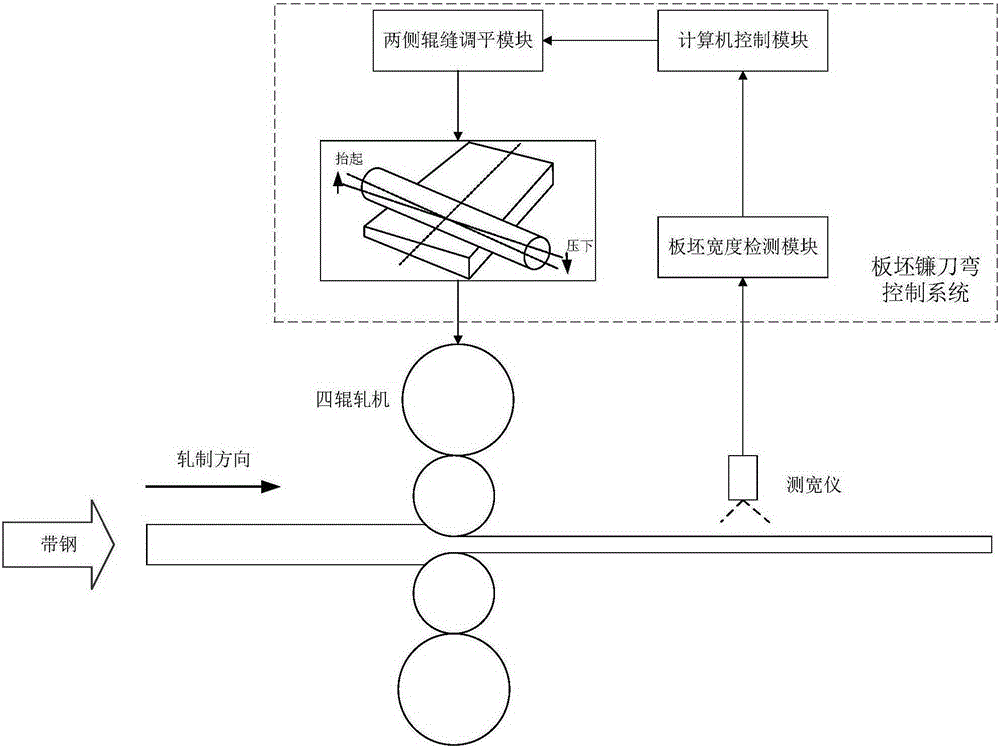

[0049] See attached figure 1 , the slab width detection module belongs to the process control system (L2), this module collects the center line offset data detected by the width gauge, calculates the bending type and degree of bending of the slab camber, and sends it to the computer control module; In order to measure the degree of camber bending, a parabola fitting is performed on the offset data of the export slab center line, and the fitted curve is as follows:

[0050] y=ax 2 +bx+c[l min , l max ]

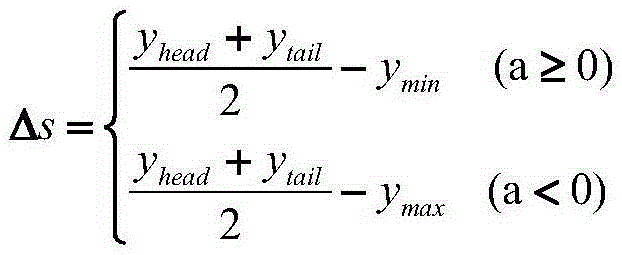

[0051] In the formula, y—indicates the offset of the slab center point in the width direction, mm; x—indicates the value of the slab center point in the length direction, mm; l min , l max ——indicates the value range of the center point of the slab in the length direction, mm; a, b, c——indicates the coefficients of the quadratic cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com