Self-adaptive correction method for differences of fuel compositions of natural gas engine

A fuel composition and engine technology, applied in engine control, machine/engine, fuel injection control, etc., can solve the problems of increasing engine misfire, difficulty in guaranteeing engine rated power, limiting the operating range and operating quality of natural gas vehicles, etc., to achieve improved control horizontal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

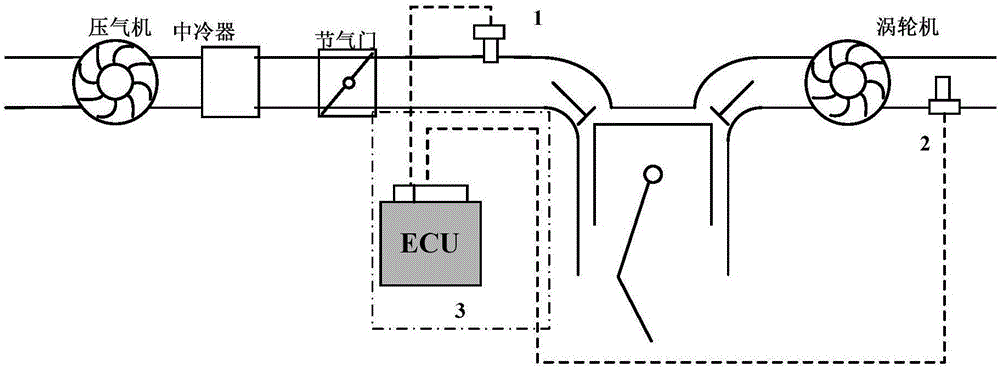

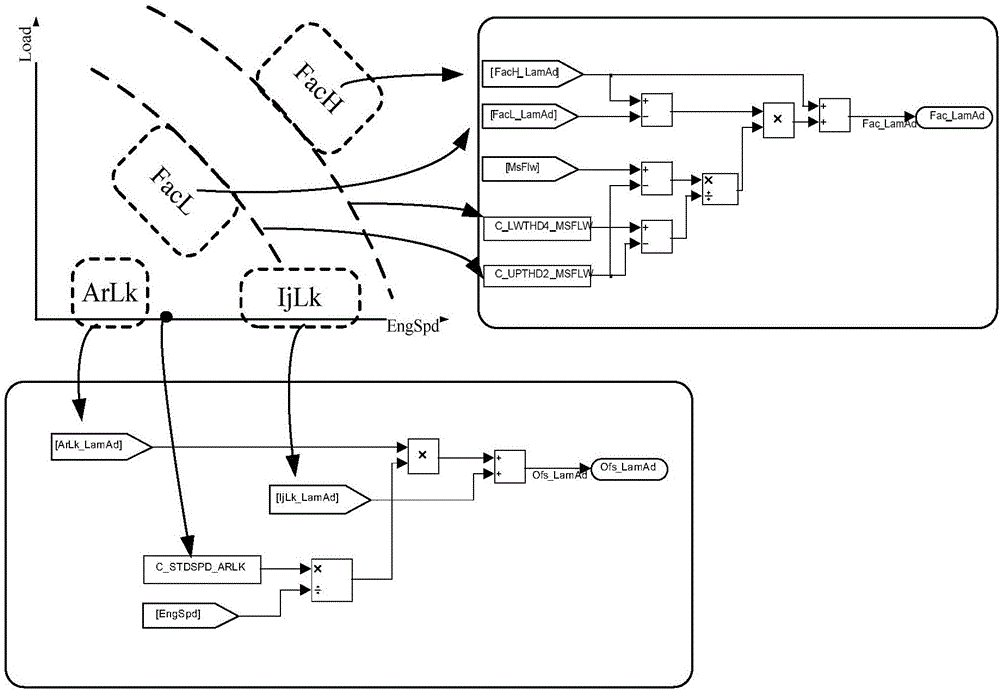

[0041] In this embodiment, a natural gas engine fuel composition difference self-adaptive method relies on the composition of a nozzle 1 for gas fuel injection, a wide-area oxygen sensor 2 for mixed gas ratio feedback control, and an engine control unit (ECU) 3 A hardware device, the method specifically includes the following steps (such as image 3 shown):

[0042] 1. According to the engine speed and load conditions, the working condition area for activating the adaptive algorithm is divided:

[0043] A. When the speed is lower than the engine idle speed × 110%, and the load is lower than 20% of the maximum torque, it is divided into low speed and low load industrial and mining area (ArLk), which is recorded as working condition area 1;

[0044] B. When the rotational speed is higher than or equal to the engine rated rotational speed × 90%, and the load is lower than 20% of the maximum torque, it is divided into a high rotational speed and low load area (IjLk), which is rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com