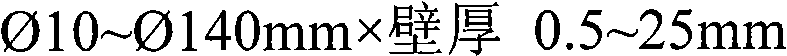

Titanium alloy TC4 cold-rolled tube and production method thereof

A titanium alloy and cold-rolled tube technology, applied in the field of titanium alloy tube and its preparation, can solve the problems of difficult processing, etc., and achieve the effects of good metal internal structure, reduced power consumption cost, and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Concrete preparation process is as follows:

[0027] 1. Made of TC4 tube blank Add paraffin wax lubricant to the inner surface of the tube billet, and roll it. The rolling deformation in the first pass is 24%, the rolling speed is 30 times / min, oxidation annealing, the annealing temperature is 800 ° C for 1.5 hours, and the scraping defect is repaired after air cooling;

[0028] 2. Add paraffin wax lubricant to the inner surface of the tube billet from the first pass, and roll it. The rolling deformation of the second pass is 28%, the rolling speed is 30 times / min, 50 passes of unilateral inner hinge, oxidation annealing , the annealing temperature is 800 ° C for 1.5 hours, and the defects are repaired after air cooling;

[0029] 3. Add paraffin wax lubricant to the inner surface of the tube billet coming down from the second pass, and carry out rolling. The rolling deformation in the third pass is 35%, and the rolling speed is 35 times / min. After rolling, each end of...

Embodiment 2

[0034] Concrete preparation process is as follows:

[0035] 1. Made of TC4 tube blank Add paraffin wax and molybdenum disulfide lithium-based grease lubricant to the inner and outer surfaces of the tube billet respectively, and carry out rolling. The rolling deformation in the first pass is 15%, the rolling speed is 20 times / min, 80 unilateral inner hinges, oxidation Annealing, the annealing temperature is 600 ℃ for 3 hours, and the defects are repaired after air cooling.

[0036] 2. Add paraffin wax and molybdenum disulfide lithium-based grease lubricants to the inner and outer surfaces of the tube blanks in the first pass, and roll them. The rolling deformation in the second pass is 38%, and the rolling speed is 30 times / min. After rolling, both ends cracked 6 cm, and the surface quality in the middle is better. Cut the ends, oxidize and anneal, anneal at 600°C for 3 hours, and repair the defects after air cooling.

[0037] 3. Add paraffin wax and molybdenum disulfide lit...

Embodiment 3

[0043] Concrete preparation process is as follows:

[0044] 1. Made of TC4 tube blank Molybdenum disulfide lubricant is added to the inner and outer surfaces of the tube blank, and the rolling is carried out. The rolling deformation in the first pass is 25%, the rolling speed is 30 times / min, oxidation annealing, the annealing temperature is 900 ° C for 1 hour, and the air cooling is repaired. scrape defects.

[0045] 2. Molybdenum disulfide lubricant is added to the inner and outer surfaces of the tube billet from the first pass, and then rolled. The rolling deformation in the second pass is 35%, the rolling speed is 35 times / min, and the unilateral internal hinge 50 passes, oxidation annealing, annealing temperature 900 ℃ for 1 hour, air-cooled and repaired scraping defects.

[0046] 3. Molybdenum disulfide lubricant is added to the inner and outer surfaces of the tube blanks in the second pass, and then rolled. The rolling deformation in the third pass is 38%, and the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com